Индивидуальный поликарбонатный акриловый круглый прозрачный пластиковый

- Категории: Other Plastic Building Materials >>>

- Поставщик: Guangzhou,Lishen,Plastic,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

custom polycarbonate acrylic round clear plastic skylight dome cover

Advantages Of Polycarbonate Skylight Domes | ||

Characteristics | Unit | Data |

Impact resistance | J/M | 850 |

Light transmission | % | 80 |

Fire resistance | GB8624--1997 | B1 (burning point:630°C) |

Range of temperature | °C | -40°C - +120°C |

Anti-UV | There are ultraviolet(UV) coating:50UM, and reduce 5um annually | |

Lightweight | It is just 1/3 the weight of acrylic dome, or 1/6 as heavy as glass skylight, and the only drawback is that it is more expenxive than either. | |

The PC skylight dome is energy efficient, environment-friendly, lightweight, weather resistant, recyclable etc. It can defense fogging due to smooth surface. | ||

Application: walkways, patios,terraces, indoor, outdoor, garden house etc. | ||

Glazing is available in thermoformed acrylic polycarbonate as single or double domes

1. The translucent Horizon System is constructed of lightweight, impact resistant, UV protected polycarbonate panels that are easy to install.

2. polycarbonate skylight design is a dry glazed, daylighting system with proven energy saving solar and thermal properties

3.we are the manufacturer of plastic domes acrylic, polycarbonate and ABS.

4. They are ultra high-quality thermoformed rooflights.

Should I choose Acrylic or Polycarbonate?*

Acrylic is a good option when on a budget, they offer great value for money and are very economical. We class these as "Fragile". Acrylic domes offer great UV resistance but have a lower fire rating.

Polycarbonate skylights are always our recommended choice as these are virtually indestructable, certified "Non fragile" and have a Fire Rating & BBA Certificate available.

Let the sun shine into your home with the skylight dome.

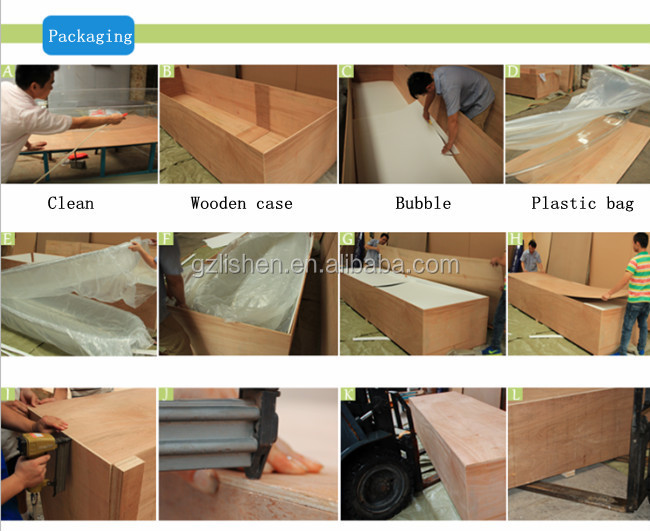

Packaging : plastic bag + Wooden case + Batten

Different situation decides to different packaging based on the product safe

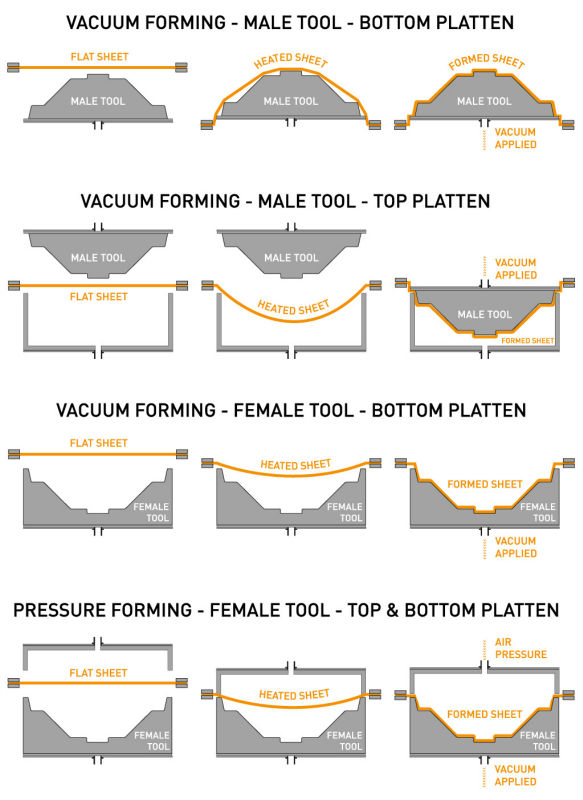

What is the Vacuum mold?

Vacuum forming is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto a convex, or into a concave, single-surface mold, and forced against the mold by a vacuum (suction of air). The vacuum forming process can be used to make most product packaging and speaker casings. It is also used to fabricate car dashboards. The first commercial manufacturer of vacuum-formed plastics was Robinson Industries of Coleman, Michigan.