DNAY800B высокоскоростная 7 моторов Bopp ПЭТ ПВХ пленка 8 цветов ротогравюрная печатная машина

- Категории: Машины для ротационной глубокой печати >>>

- Поставщик: Zhejiang,Deguang,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Deguang -Printing In Life

Machine Running Vedio Link: http://v.youku.com/v_show/id_XNzEyMTc0ODMy.html

| Technical parameter: | ||

| Model | DNAY800B | DNAY1100B |

| Web width | 800mm | 1100mm |

| Printing speed | Max 120m/min | Max 120m/min |

| Print cyl. dia. | Φ100-350mm | Φ100-350mm |

| Rolling material dia. | Φ570mm | Φ570mm |

| Print cyl. cross adjustable | 30mm | 30mm |

| Registering accuracy | ±0.1mm | ±0.1mm |

| Total power | 132kw | 154kw |

| Weight | 14000kg | 15000kg |

| Overall dimensions(L×W×H)(mm) | 13500x3000x3100 | 13500×3300×3100 |

| the specification is based on 6 colors | ||

Seven inverter motor controlling system

1.Programmable controller control the main motor, rewinding and unwinding motor, the speeding and decelerating synchronously to ensure the same linear speed and stable film tension of rewinding and unwinding traction during the printing process and auto roll-changing. Set the tension value of the rewinding and unwinding traction by adjusting the precision reducing valve, and make it closed loop controlling with potentiometer and inverter motor. The advantage of the swing arm is that it can buffer the fluctuation of the film tension and ensure the registration accurate.

2. The feature of seven inverter motor controlling: Less rewinding waste, better registration stability

1):Save much material, ink, solvent and power when the capacity is huge.

2):Rewinding speed 120m/min, rewinding waste 5m

3):Save ink, solvent, power 25%,,reduce the cost largely.

3.The comparation on the rewinding waste of seven inverter motor controlling and magnetic powder auto tension controlling:

Magnetic powder auto tension: Rewinding speed 120m/min, rewinding waste 80m.

Seven inverter motor controlling:Rewinding speed 120m/min, waste 5m.

1. Usage: It is suitable for BOPP, PET, CPP, PVC and combined film and paper with the same properties. Its printing speed is 120m/min, mechanical speed is 130m/min.

2. Seven frequency motor controlling system.

3. PLC control.

4. Automatic splicing and cutting.

5. Floating roller to adjust tension

6. Outside unwinding and rewinding dual station turret, inching rotation.

7. Two unwinding shaft is controlled by two frequency motor.

8. Unwinding traction adopts frequency motor.

9. Unwinding and rewinding air shaft

10. Pneumatic pressing roller.

11. Shaftess printing cylinder.

12. Automatic registration with video inspection.

13. Pneumatic doctor blade.

14. Pneumatic ink pump.

15. Electric heating or gas heating or oil heating.

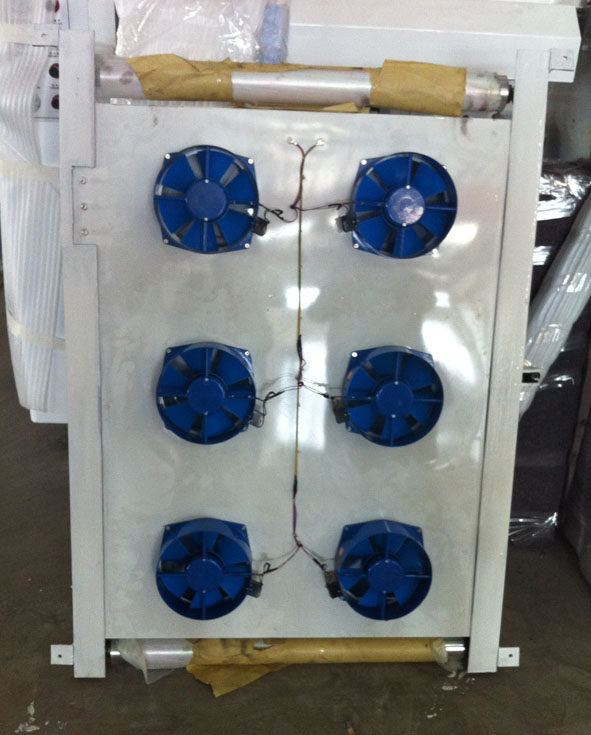

11.Independent drying and suction exhausting system,air circulated,max recycled rate 50%,outside oven increase the amount of blowing air to ensure the drying.

12. Assisted oven on the top of last printing unit can prevent the last color adhesive to the printing cylinder when the color cover the whole cylinder, making the film completely dry.

13. Pre-heating system

14. Water cooling and air cooling, two option.

15. Waste air eliminating tunnel.

16. Two rewinding shaft is controlled by two frequency motor.

17. Rewinding traction adopts frequency motor.

18. Main motor: Frquency motor

19. Cast iron wallboard,thickness is 70mm

Details Picture of Rotogravure Printing Machine:

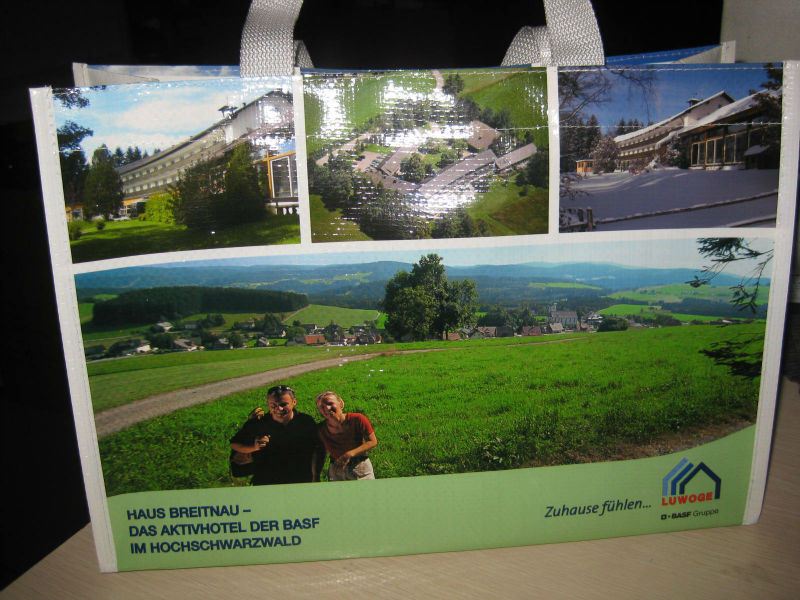

Our Printing Products sample :

Our Working Shop:

We are In Exhibition :

Certificate of Rotogravure Printing Machine:

ZheJiang Deguang Machinery Co.,Ltd:

30 Years History Consistent and Stable Quality,Your best Choice!!!