Стандартные зубчатые наконечники с Оловянным покрытием HSS

- Категории: Плита >>>

- Поставщик: Chongqing,Yuqing,Machine,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

HSS DIN3972 Standard Gear Hobs with TIN coating

Accuracy :ClassAA ,ClassA and ClassB

1.Nomal tooth profile parametere

Module | M |

Pressure Angle | PA=20° |

Addendum | S+F=1.25m |

Working Depth | D+F=2.25m |

Total tooth height | h=2.5 |

Clearance of tooth bottom | CK=0.25 |

Tip radius | r=0.3m |

Pitch | np=π.m |

Tooth Thickness | sn=np/2 |

2.Specifications:(mm)

Module | Outside Dia. | Overall Length | Hole Dia. |

1 | 50 | 32 | 22 |

1.25 | |||

1.5 | 40 | ||

1.75 | 63 | 50 | 27 |

2 | |||

2.25 | 71 | 55 | |

2.5 | |||

2.75 | 63 | ||

3 | |||

3.25 | 80 | 71 | 32 |

3.5 |

Module | Outside Dia. | Overall Lenngth | Hole Dia. |

3.75 | 90 | 80 | 32 |

4 | |||

4.5 | 90 | ||

5 | 100 | 100 | |

5.5 | 112 | 112 | 40 |

6 | |||

6.5 | 118 | 118 | |

7 | 125 | ||

8 | 125 | 132 | |

9 | 140 | 150 | |

10 | 150 | 170 | 50 |

Notes:(1)Module 11-14 can also be orderded

(2)Hobs With inch hole of 7/8,1,11/16,11/4,11/2,13/4 and 2 in can be made.

(3)Gear hobs of JIS,BS,DIN and ANSI standards can be ordered too

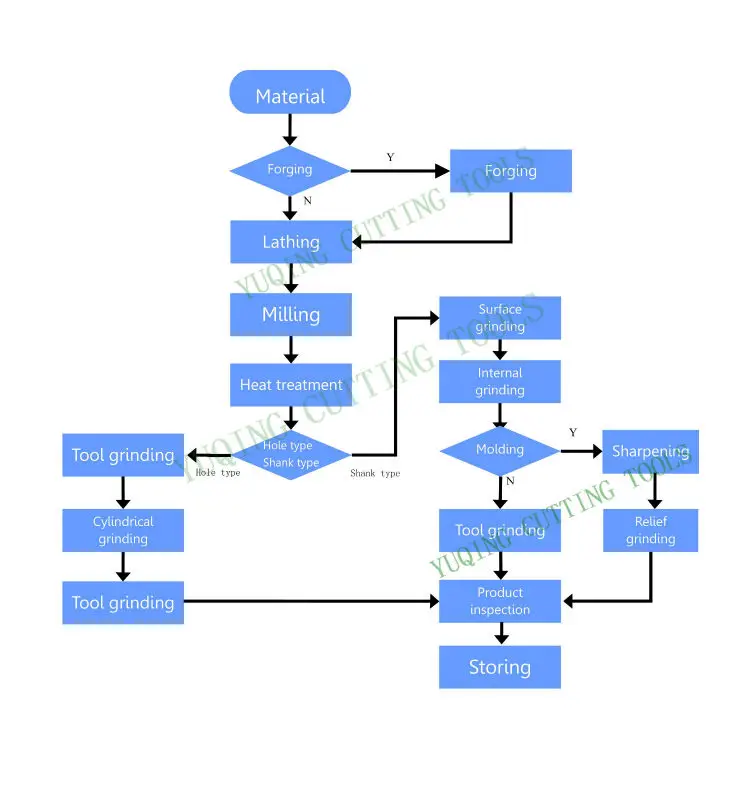

Production process of milling cutters

Material Introduction:

A. W6Mo5Cr4V2 (GB) M2( ASTM), S6-5-2(DIN), SKH51(JIS)

chemical composition:C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

main application:It is widely used for making all kinds of cutters and durability cold-work die

B. W6Mo5Cr4V2Co5 (GB), M35( ASTM), 1.3243(DIN), SKH55(JIS)

chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

main application:It is often used for making blades with high-speed and great cutting difficulty as it’s good abrasive resistance

W6Mo5Cr4V2(M2),W9Mo3Cr4V(W9),W18Cr4V(W18),W6Mo5Cr4V2Al(M2Al),W6Mo5Cr4V2Co5(M35),W2Mo9Cr4VCo8(M42),W4Mo3Cr4VSi(4341),W4Mo2Cr4VSi(4241)