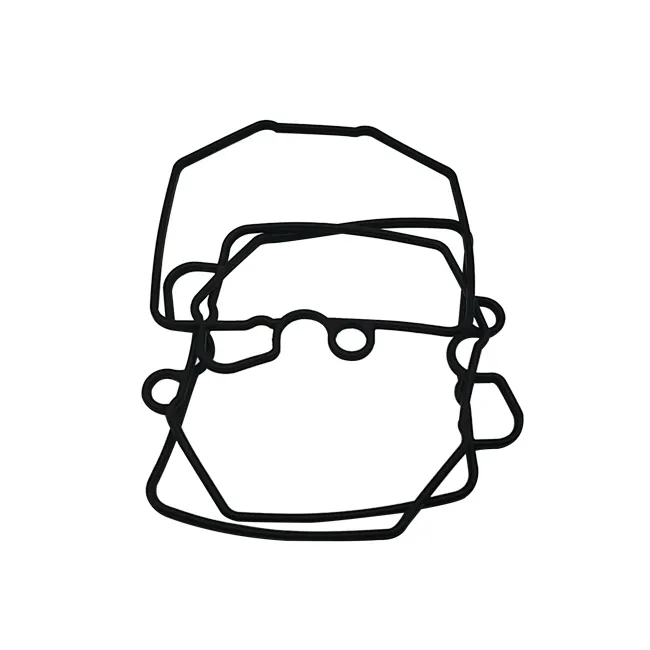

Неопреновая резиновая плоская прокладка

- Категории: Прокладки >>>

- Поставщик: Dongguan,Heng,Qiang,Rubber,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

QUALITY CONTROL

Laboratory room 实验室

\t\t\t\t\t\t\t\t\tOur Company \t\t\t\t\t\t\t

RUBBER SHOW

Electronics Fair

In HK

CES Fair

In Hk

In Hk

Aapex Fair

In USA

K show

In Germany

\t\t\t\t\t\t\t\t\tMold Work Shop \t\t\t\t\t\t\t

Capacity | 150 sets/Month | ||||||

Machine | 11 sets CNC machines, 6 EDM machines(including Mirror EDM machines), 6 sets milling machines | ||||||

Mold type | Compression,Transfer,Injection(Cold&hot runner) | ||||||

Mold steel | NAK80,S136, P20,S50C | ||||||

Biggest mold size | 1200mm | ||||||

Main products | roller molds, automotive rubber mold, Liquid silicone rubber mold, no flash corner mold,Plastic mold | ||||||

Export Market | Japan;Germany, USA,UK,Southeast Asia, etc. | ||||||

Software | Mastercam ,UGNX,AutoCAD ,SolidWorks , Pro-E | ||||||

Lead time | Prototype :3-7days Production mold: 10-15 days | ||||||

Our workshop view

Capacity | 300 tons silicone rubber compound each month | ||||||

Machine | 46 sets compression machines11 sets liquid silicone injection machines 10 sets Solid rubber injection machines 3 sets special customized Wire harness connector machines based on Amphenol's requirement 7 sets plastic injection machines | ||||||

Michine pressure | 50 to 350 tons | ||||||

Main products | Widely used in Automotive& Ev new energy,industry,Medical appliance,Artificial intelligence,house-hold appliance, toy,bathware,kitchenware,precision die-cutting etc. | ||||||

Export Market | Japan;Germany, USA,UK,Southeast Asia, etc. | ||||||

WHY CHOOSE US

1. Manufacturing and exporting experience for over 24 years. ISO 9001&14001 &IATF16949&ISO 13485 approved.

2. Products are supplied to over 50 countries.3. One-stop service from rubber molded parts to rubber extruded parts. Save time and save money for you.

4. In-house mold design and building capabilities

5. Injection, injection transfer, compression, extrusion and silicone liquid injection capabilities

6. Our product are in high quality

1)No reclaimed rubber used to ensure quality.

2)Auto rubber milling production line.

3)Complete in-house custom compound formulating and mixing.

4)Rubber compound is tested before production

2)Auto rubber milling production line.

3)Complete in-house custom compound formulating and mixing.

4)Rubber compound is tested before production

7. Rubber compound can be RoHs, Reach. Other certificates can be done according to different customer's demands

8. Strong advantage for auto rubber part. PPAP, MSDS, IMDS available.

9. Keep secret to your idea and your design.

10. 24 hours (two shifts) / 6 days for production.

11. Professional design team, mold maker engineer. OEM/ODM service.

12. Professional QC and R&D teams to assure high quality

13. Professional sales team. Good English capabilities and communication skills.

14. Prompt delivery. For prototype: 3-7 days, Production orders can be arranged specially to meet customer’s urgent demands

8. Strong advantage for auto rubber part. PPAP, MSDS, IMDS available.

9. Keep secret to your idea and your design.

10. 24 hours (two shifts) / 6 days for production.

11. Professional design team, mold maker engineer. OEM/ODM service.

12. Professional QC and R&D teams to assure high quality

13. Professional sales team. Good English capabilities and communication skills.

14. Prompt delivery. For prototype: 3-7 days, Production orders can be arranged specially to meet customer’s urgent demands

CONTACT ME