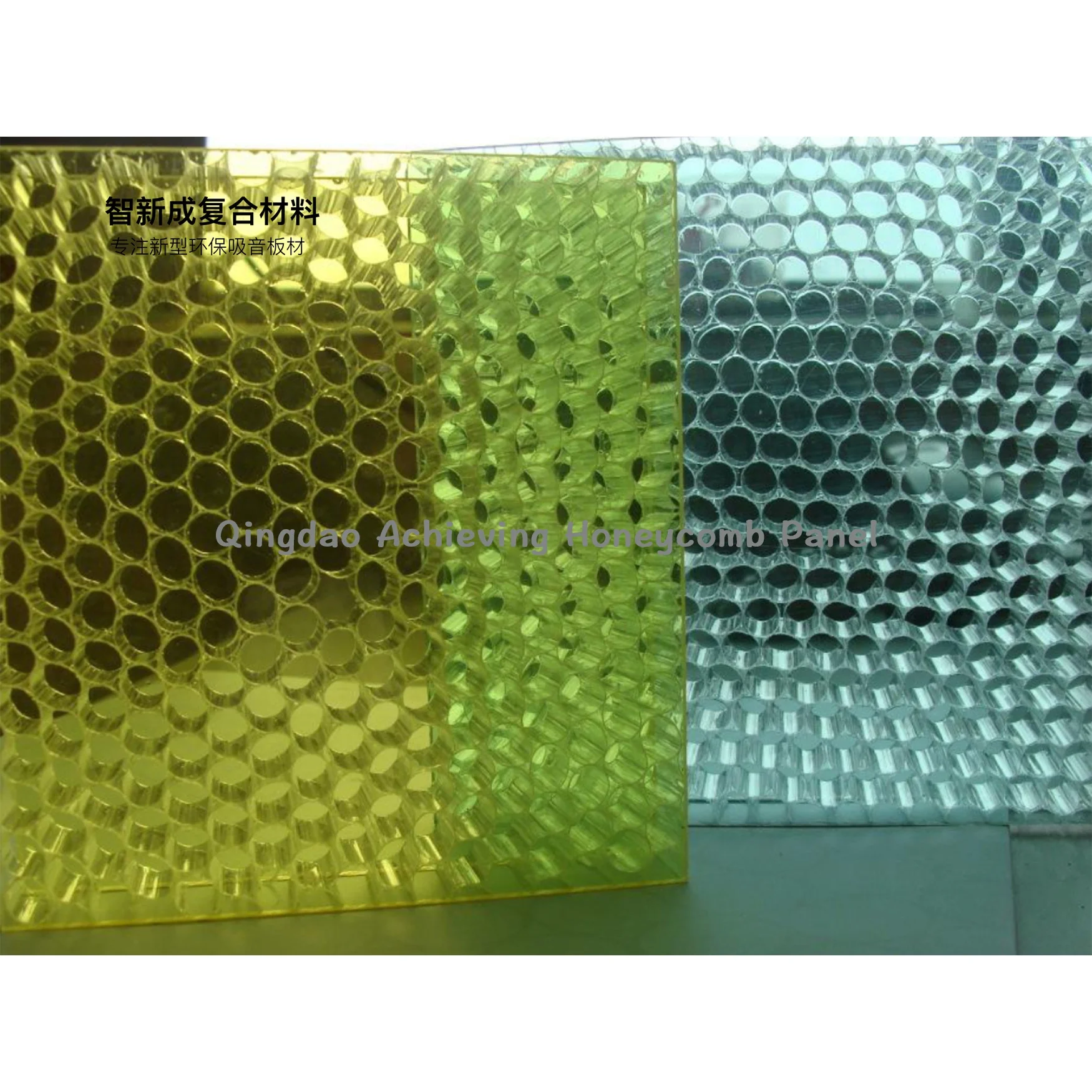

Структурная изоляционная панель для внутренней декоративной полипропиленовой/поликарбонатной сотовой облицовки

- Категории: Golf >>>

- Поставщик: Qingdao,Achieving,Honeycomb,Panel,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Our PP honeycomb sandwich floor which is sandwich structure honeycomb core and top bottom plywood surface.

PP honeycomb core Specification

PP8 (Cellcore diameter is 8mm,capacity is 85kg-95kg/m ³ )

PP10 (Cellcore diameter is 10mm,capacity is 75kg-85kg/m ³ )

PP12 (Cellcore diameter is 12mm,capacity is 65kg-75kg/m ³ )

Light weight, high compressive strength,anti-water,anti-humidity honeycomb can be used as structure in floor,ceiling,wall. .Besides PP honeycomb can cut down body weight ,increase speed, save energy when honeycomb structure make guarantee for body strength. Hereinforce our PP honeycomb widely used in boat,yatch,port,bridge,truck body,building,FRP and so on

FEATURES:

1>light weight with stiffness strength, high light

transmission,no focusing.

2>Heat isolation

3>Excellent dielectric properties

5>Recyclable

6>Light yet strong

7>Conductive grades available

8>Small cell sizes at high density configurations.

Application:

*1>Marine

*2>furniture

*3>advertising display

*4>transportation as structural material such as hull, deck, bulkhead, tank, canopies and accessories

*5>closet,partitions

*6>truck body, car roof, and trunk.K

| Length Max | 2500mm |

| Width Max | 1300mm |

| Normal size | 2440*1220mm |

About Company

Qingdao Achieving Honeycomb Panel Co., Ltd. is a privately owned company which was found in 2008. This is the second company built up by the owner and is mainly focusing on the plastic honeycomb composite panels, which is different from the owner’s first company – a mechanical factory founded in 1999. The products includes but not limited to hardware, machinery and equipments, rubber and plastic products and etc. Our products have always been following the demand trends on the market. And our products’ reliable quality and our good service have brought us a good reputation home and abroad. We are willing to improve and develop new products with friends and clients together. We are inspirited by innovations. We’d love to have more experiences on developing?new markets and new applications for our clients, and creating better products.

Factory Information

Factory Size | 3,000-5,000 square meters |

Factory Country/Region | Hongbu Community Liuting Town Chenyang District,Qingdao |

No. of Production Lines | 5 |

Contract Manufacturing | OEM Service Offered |

Factory Display

How does achieving honeycomb acoustic board work?

Achieving acoustics is based honeycomb,its cell structure could aborb,reflecting,consume

the energy of sound vibration, to keep noise minimum.

Honeycomb sheet mat advantage

It is strong and flexible,not grow together like rubber for example and have air in side its cells,

ventilatable and not crush,dissipating sound as it pass through the mat rather than deadening.

How to use Achieving acoustic board

Wildly adopted by commercial buildings, apartments, noise reduce for adjacent floors

It is a 5mm thickness mat,common size 1220*2440mm or 1150*2300mm,

Made of polycarbonate or polypropylene.density is around 70-90kg/m3,

It is laid and glued onto the floorslab’s surface, easier be bond and quickly ready for

Installation of tiles or timber flooring.

How do I know your quality?

We are a company/factory with more than 12 years’ experience in the honeycomb industry. During these years, we have done many businesses with the client from all over the world. If you still concern about the quality product, feel free to contact us ask for the sample.

Can you deliver to the my city?

We are qualified export factory and trading company, have lience anthoritied by Goverment.