Лидер продаж в Южной Африке Китай лучшие кирпич силу проволочной сетки сварочный

- Категории: Контактная сварочная машина >>>

- Поставщик: Jiaoyang,Welding,Industries,Hebei,Co.,Ltd

Поделиться:

Описание и отзывы

Характеристики

Brick force mesh welding machine

Brick force mesh welding machine is mainly used to produce brick force meshes. Brick force mesh is widely used in construction, hollow wall reinforcement, increase the elasticity, to prevent wall cracks, is a good building auxiliary material.

This machine is used to produce the brickforce mesh roll from 1.6-3.5mm wire . This brickforce mesh is very popular in Africa, South Africa, Malawi,Zamiba

Parts of product

A. Main welding machine

B. Wire payoff and shelf

The sensors are also equiped to monitor the line wires. It has 6 springs between the yellow device and blue frame,which can regulate 6 wire payoffs are included.

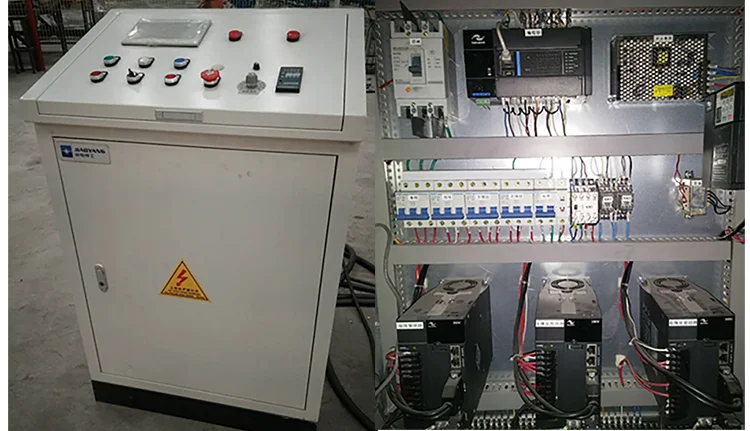

C. Control cabinet

1.Taiwan famous brand PLC and touching screen

2.pneumatic testing, servo alarm

3.mesh size is set from PLC , welding current and welding time is also set from PLC

Basic information

1.specification

Items | Parameter |

Mesh width | 75mm, 115mm, 230mm (50-230mm adjustable ) |

Electrode no. | 4 |

Wire diameter | 1.6-3.5mm |

Cross wire space | ≥20mm |

Material | Low carbon wire ( carbon contains ≤0.2%,tensile strength ≤550MPa |

Welding speed | 60-90 times/min. |

Transformer | 36KVA×1set |

Line wire feeding | Coils wire feed from coil by servo motor |

Cross wire feeding | Coils wire feed from coil by servo motor |

Welding pressure | Pneumatic |

Welding method | Controlled by SCR |

Mesh pulling | Automatic rolling machine, one time making two coils |

Controller | PLC with touch panel |

Mesh length setting | Automatic cut |

2.function features

1.The automatic brick force mesh welding production line is a new research and development project designed for some countries in Africa.

2. It works with coil wire feeding ,the double work position welding and automatic centerless grinding roll and shear mesh .

3. Rolling mesh device is mainly composed of the mesh tension ,guide rolling mesh ,cutting and dial the mesh devise ,which has greatly improve the work efficiency ,eliminating the need of for manual downtime cut mesh rewinding.

3.application

1.it is mainly used to produce brick force meshes

2.Brick force mesh is widely used in construction ,hollow wall reinforcement ,increase the elasticity ,to prevent wall cracks ,is a good building auxiliary material

3.Brick force mesh is used for the foundation ,wall ,ect. It has higher request for strength and stability of place and the local stress where it is reinforced in the brick and block

4.Brick force mesh is used in the reinforcement of the brick and block construction every key points of the cement mortar ,so that brick and cement mortar to form an intergral whole structure ,the maximum absorption stress and vibration ,excellent and anti-crack performance

1. Engineers is aviliable for service overseas.

Service such as install and adjust the wire mesh welding production line, traning the wire mesh mesh operator.

2. Warranty: 1 years since the shipment date of the wire mesh production line.

Hebei jiaoyang wire mesh machine co.,ltd

1. Employees: 243Advanced steel wire mesh welding machine for sale

2. Engineers and technicians: 34

3. Processing equipment: 105 sets

4. Plant area: 133,000 square meters

5. Office area: 3,700 square meters

6. National patents: 63

7. Assets: USB 20,000,000

8. Annual equipment export amount: 360 sets

9. Annual equipment output: 800 sets

10.Foreign markets: Asia, Middle East, America, Africa

workshop:

The machine will be packed with plastic bags, spare parts in carton box.

Special packing is available according to customers' requirements.