Ультразвуковая машина для фиксации страз ультразвуковой сверлильный станок нижнего

- Категории: Apparel & Textile Machinery >>>

- Поставщик: Guangzhou,Dashan,Ming,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

ultrasonic rhinestone fixing machine,ultrasonic drilling machine for lingerie

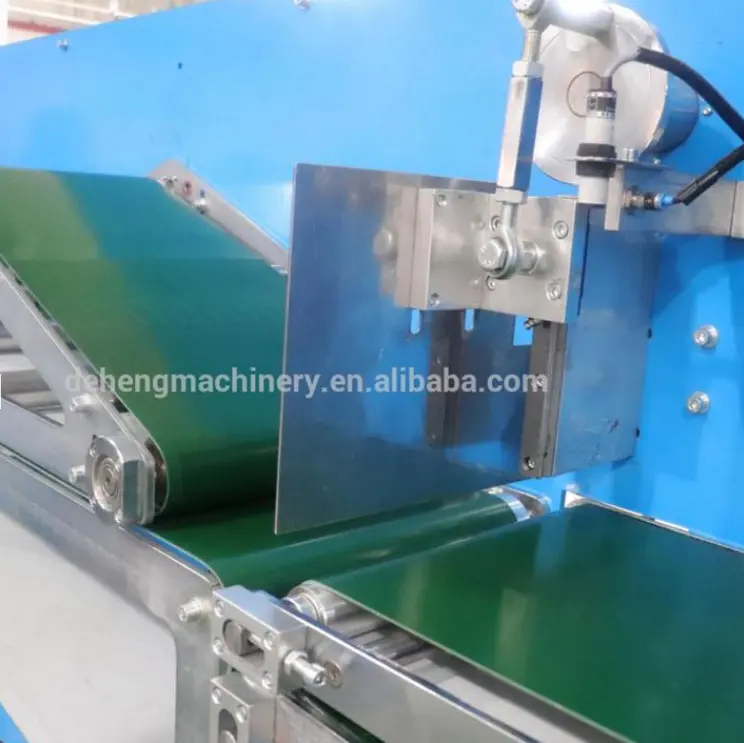

Multifunctional Ultrasonic Hot-fix Setting Machine

For the sake of preventing fire,electronic shock,injury during the work and other accidents , please do comply with the safe attention proceeding mentioned in this manual .

Before using , please read the manual carefully , and operate the machine correctly.Please keep the manual on the places available for users easily check after reading it.

Part One :Characteristics & Purpose

The product is a portable welder , which integrates with safety, craft of advance, high efficiency ,convenience etc,which has a big advantage in structure and craftwork, especially in the aspect of safety. We combine the advantages of domestic and overseas technics with the actual situation of our own , making efforts to ensure the using safety of the products.

The effect pictures of ultrasonic rhinestone fixing machine,ultrasonic drilling machine for lingerie:

Part Two :Working Principle

It adopts the principle of high-speed vibration heat-energy transfer, under the effect caused by strength,vibration and friction are generated on the surfaces of two processed goods and they melt down swiftly.When vibration stops,the surface and process complete.The welder using in the field of machining diamond and bead in shoes manufacturing , clothes manufacturing , embroidering , printing etc. and also can be uses for the welding of small size product.(e.g.PVC,Umbrella)

Part Three:Main Structure

- It is galvanization armor plated , the whole machine connects to the ground to dispel heat, and also have the additional pipeline-heat fan. All of the wires adopt particular structure and connecting well.The energy converter is made of particular high-quality alloy , and the cover is made of light insulated material.

- The switch is imported.

- The pin of power wire used the three-ply cables,and safe to connect to the ground.

- The aspiratory pump is the electromagnetic air compressor.

Part Four:General Operating Notice

- Work area should be clean. Mess-up will cause the accident .

- Make sure about the suitable working environment , it should be displayed in cool and dry places , keep away from explosive and flammable goods.

- Caution about electronic shock , avoid the machine to contacts with radiator , refrigerators etc.

- Make kids and non-staff keep away from the work area .

- If not used , please display the ultrasonic welder on the dry places and make sure that kids aren’t able to touch it , lock it simultaneously , do not display it the ground directly.

- The wire should keep away from the hot resource and oil.

- Tools (power wire and energy converter and so on) should be maintained well and cleanly . so that they can exert their effect fully . For example ,if any troubles are detected , users should contact service to repair it.Handle (energy converter should keep dry ; prevent grease and water.)

- Changing the connecting measure of output wire is forbidden, if any troubles are detected , please contact service to repair it.

- If not used , unplug the socket.

- In order to avoid the accident , do not use the ultrasonic welder to do extra task out of the rules.

- Do not use the solvent such as gas and alcohol to clean the machine and accessories . If needed , please use soft cloth dipping some water .

- Pay more attention to control the device fully.

Part Five:Notice of Using Ultrasonic Welder

Assembling the machine correctly , the interface of output line should be locked closely.

Sucker should be inserted into nozzles directly,and lightly pick it out.

The transfer is not allowed to face to irrespective things.

Part Six:Before Work

- Power:The power used should comply with the voltage requestes.

- Switch of the power:Make sure the switch is wellbalanced , press up to switch the indicator light on , and press down to off.

- Switch of air pump:Press up to switch the indicator light on , when pump working , it’ll make noise , you can switch it off .

- Manual Switch:Press up to switch it on and press down to switch off , you can also use the foot pedal to operate it .

- Output: Connect to energy converter , output ultrasonic.

- Nozzle:Direct interface of sucker and pump.

- Additional Switch: Power import wire , connect wiring box to footing switch.

- Fuse:When power malfunction happens , the fuse will break automatically to avoid the destroy of machine and occurring of accident.

- Input of power: The interface connected to the wiring box.

Part Seven : Module of Energy

- Portable vibration canister is made of light insulated material , in the exterior is the ultrasonic controlling switch , and the interior is converter and the welding head . Please aim at the spare parts when working , and push the switch lightly , make sure it can work smoothly.

- The welding head , to communicate the ultrasonic waves from the converter to the spare parts.

Part Eight : Operation

1.Turn on the power . And pilot lamp will be on.

2.Check the ultrasonic , press the testing switch , you will feel oscillating and warm touching the welding head . If it cries or no oscillations , no temperature , please check below : (1) did it connect between welding head and the converter . (2)The welding head was broken. (3)The converter broken.

3.Time of setting ultrasonic : it can be adjusted according to the situation of the diamond and bead . Usually it should be set at 0.1~0.5s. the converter should be vertical on the stones , then press the switch and it work automaticlly,moving the converter away.

4.When the machine is used for a long time , Please clean the pump when the welding head can’t suck well.

5.After a long time to use , the welding head may be abrasive on the surface , please change the head when necessary ( make sure it was turn off when changing ). If the machine out of the way, please send it to us.

6.It is used very broadly in the filed of solder diamond and bead in shoes manufacturing, clothes manufacturing etc.