Винт и цилиндр 135 мм для экструдера корма собак с двойным

- Категории: Plastic & Rubber Machinery Parts >>>

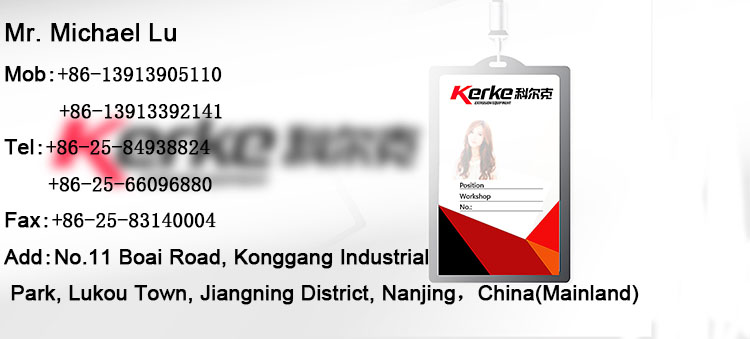

- Поставщик: Nanjing,KERKE,Extrusion,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

135mm screw and cylinder for Dog food twin screw extruder

1. ABOUT US:

2. WHY CHOSSE US:

1. Product introduction

Twin screw extruder screw element:

· convenient interchangeability by agile combination.

· fulfill efficient self-cleaning, transmission, compounding, pressure-forming, etc.

· made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by special treatment.

Assembled together, they will become twin screw which are essential and key part of extruders for material to

transmission, shearing and plasticization.

Twin screw extruder screw element parameter:

Model | Screw Major Diameter (D/mm) | Screw Minor Diameter(d/mm) | D/d | Center distance (mm) |

KTE-20 | 21.7 | 14 | 1.55 | 18 |

KTE-25 | 25 | 16.1 | 1.55 | 21.2 |

KTE-35 | 35.6 | 23.6 | 1.51 | 30 |

KTE-50 | 50.5 | 32.5 | 1.55 | 42 |

KTE-52 | 51.4 | 33.8 | 1.52 | 43 |

KTE-60 | 59.6 | 43.5 | 1.37 | 52 |

KTE-65 | 62.4 | 40.4 | 1.54 | 52 |

KTE-68 | 69 | 49 | 1.40 | 60 |

KTE-70 | 70.6 | 47.4 | 1.49 | 60 |

KTE-75 | 71 | 47 | 1.51 | 60 |

KTE-95 | 93 | 61 | 1.51 | 78 |

2. Certificate:

Presales service:

>introducing in detail features and application of the products to customer

>Selecting economical and practical machine & equipment for customer

>Providing operation data of the related machine & equipment

>Providing means of trial performance for customer

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment

>Communicating in time the manufacturing progress of the machine with user

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training

>Filling in detail customer’s information

>Providing long-term maintenance service and spare parts

>Giving technical support to customer for developing new product

>Providing free maintenance for a year