Описание и отзывы

Характеристики

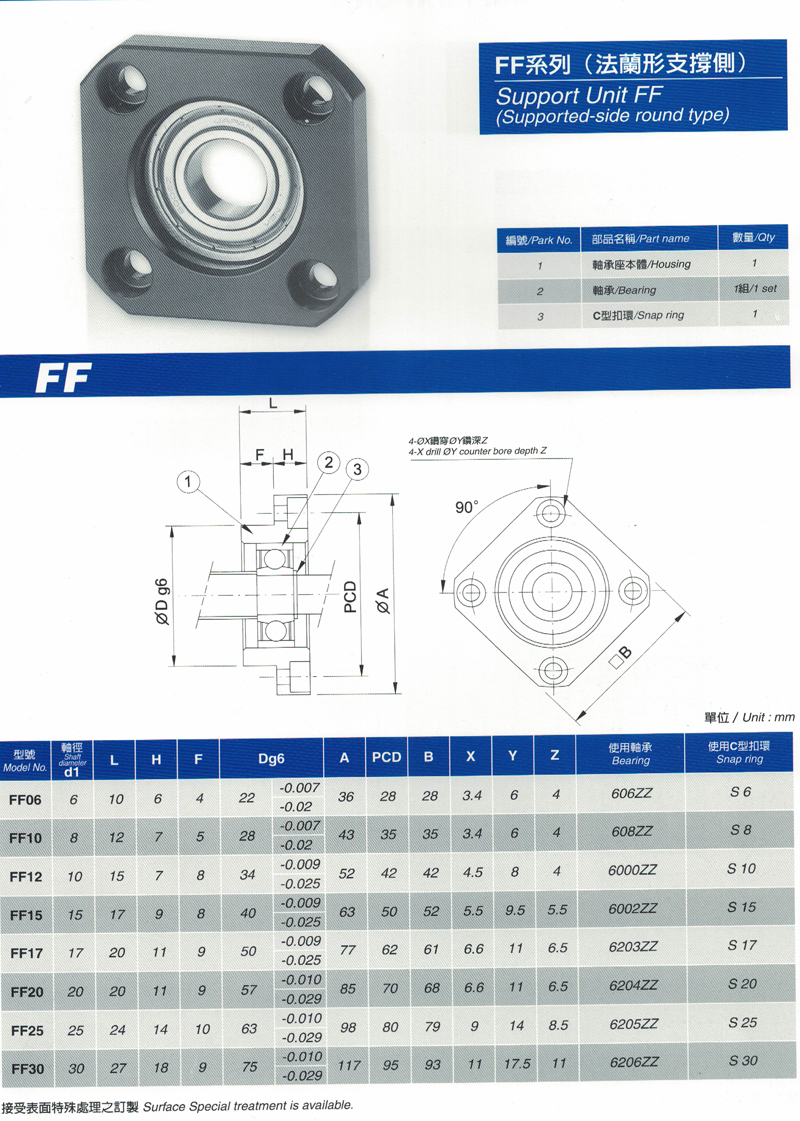

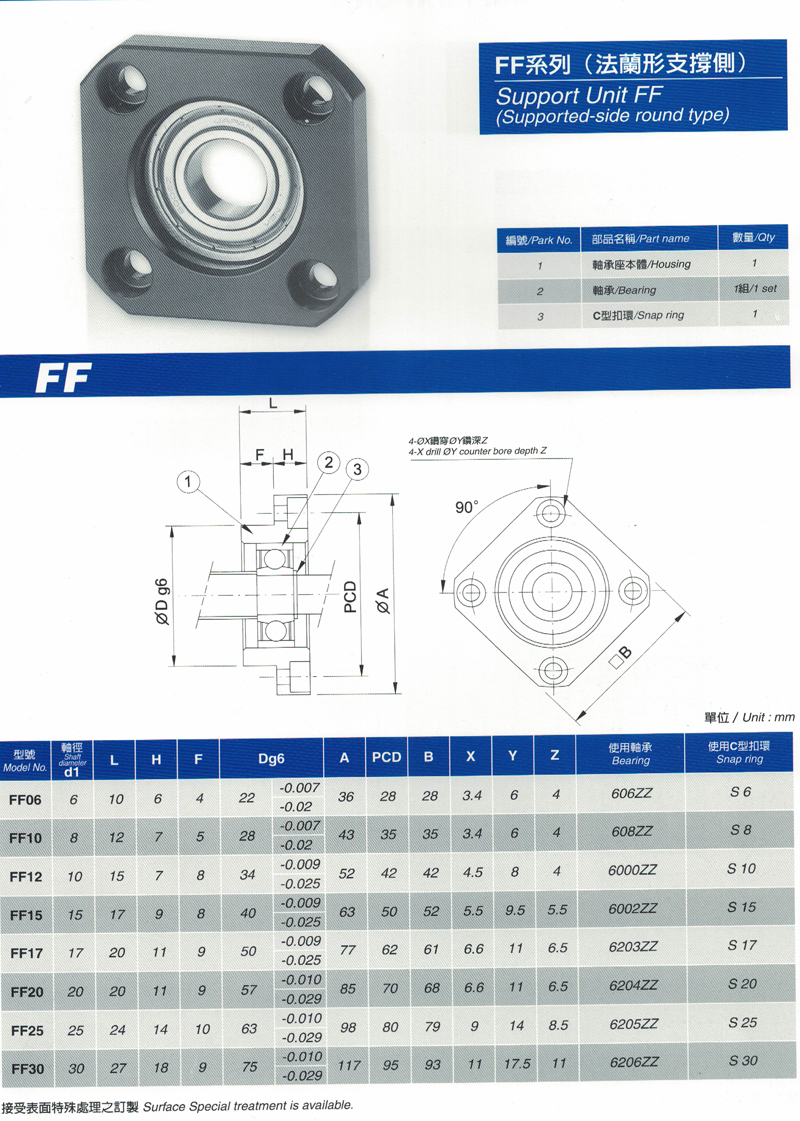

Flange Type FF25 support for ball screw

Support unit of the ball screw Details: |

A Different Name |

support unit,fixed-side support,supported-side rectangular typer |

Size |

Following list |

Brand |

NJSKT, FST, TBI, SYK |

model |

FF25 |

Minimum quantity: |

1 piece

|

Snap Ring Size

|

S 25

|

Shaft Diameter

|

25 mm

|

Precision: |

C7,C5,C3 |

Bearings

|

Deep Groove Ball Bearing |

Lubrication: |

grease |

Seal types |

Double sealed |

Material: |

chrome molybdenum alloy steel |

Packing |

original color box packaging,OrWooden Carrying Case. |

Product Description

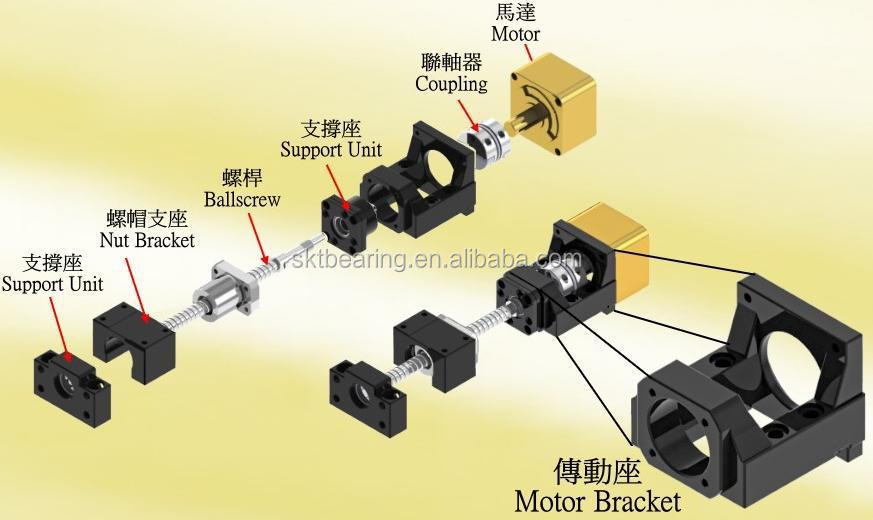

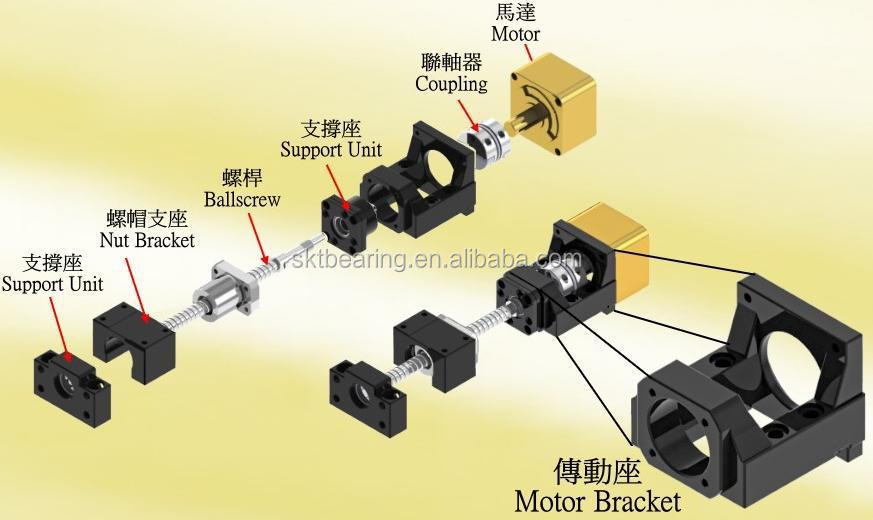

Ball Screw Support unit

- The Support Unit comes in six types: models EK, FK, EF, and FF, which are standardized for standard Ball Screw assembly provided with finished shaft ends, and models BK and BF, which are standardized for ball screws in general. The Support Unit on the fixed side contains a high precision JIS Class 5-compliant angular contact ball bearing provided with an adjusted preload.

- The ball screw of the supported side rectangular used the deep groove ball bearings with the high preformance and high accurauy.

- NJSKT bearings offers a full range of support bearings to be fitted on the machined ends of precision rolled ball screws.

Fixed-slide +Supported side

EK6+EF6 FK6+FF6

EK8+EF8 FK8+FF6

EK10+EF10 FK10+FF10 BK10+BF10

EK12+EF12 FK12+FF12 BK12+BF12

EK15+EF15 FK15+FF15 BK15+BF15

BK17+BF17

EK20+EF20 FK20+FF20 BK20+BF20

FK25+FF25 BK25+BF25

FK30+FF30 BK30+BF30

BK35+BF35 BK40+BF40

Also we can provide Linear guides and Ball screw

Drawing of support unit

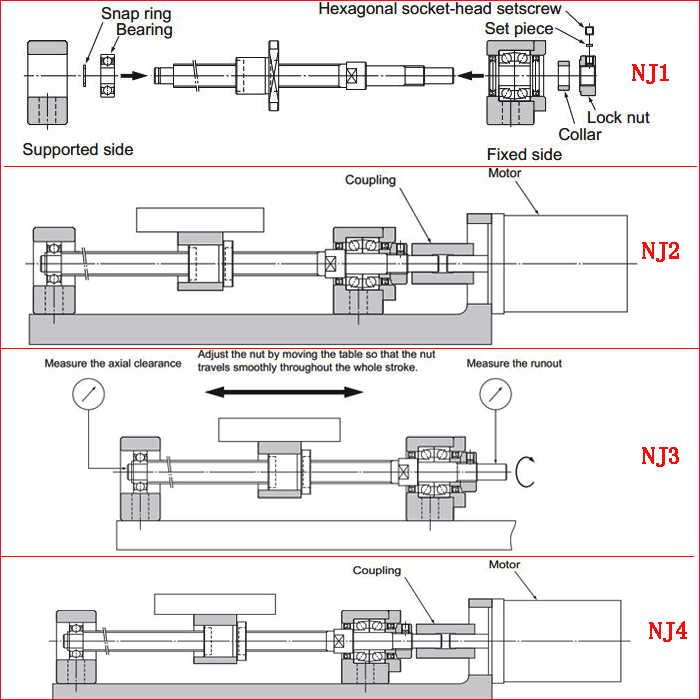

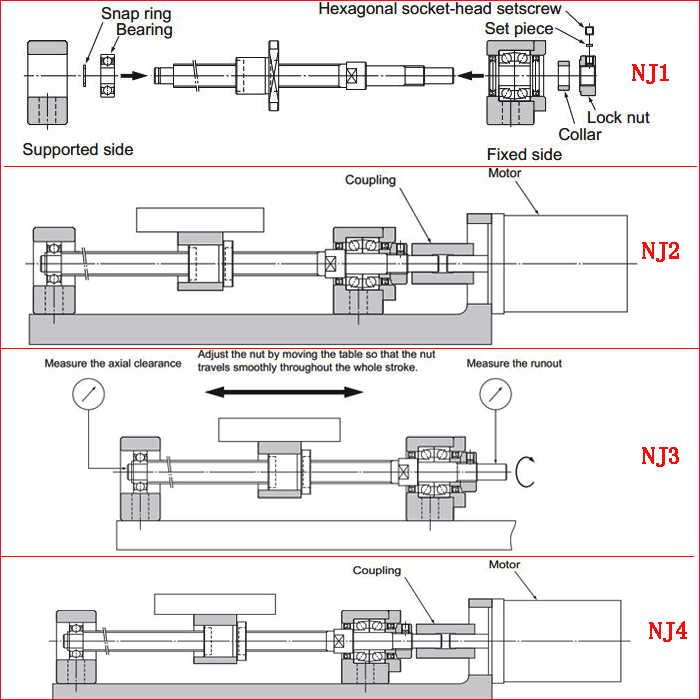

Mounting procedure

- Installing the suport unit( NJ1)

- Install the fixed side support unit with the screw shaft.

- After inserting the fixed side support unit,Secure the lok nut using the fastening set piece and the hexgonal socket- head setscrews.

- Attach the supported side bearings to the screw shaft and secure the bearing using the snap ring,And then install the assemblu to the housing on the supported side.

- Installation onto the table and the base.(NJ2)

- If using a bracket when mounting the ball screw nut to the table,insert the nut into the bracket and temporarily fasten it.

- Temporarily fasten the fixed side support unit to the base.Nowpress the table toward the fixed side support unit to align the axial center,and adjust the table so that it can travel freely.

- Press the table toward the fixed-side support unit to aligh the axial center,Make the adjustment by reciprocation the table several times so that the nut travels smoothly throughout the whole stroke,and teporarily secure the support unit to the base.

- Checking the accuracy and fully fastening the support unit.(NJ3)

- While checking the runout of the ball screw shaft end the axial clearance using a dial gauge,fully fasten the ball screw unt,the nut bracket, the fixed side support unit and the supported-side support unit.

- Connwction with the motor(NJ4)

- Mount the motor bracket to the base.

- Connect the motor and the ball screw using a coupling

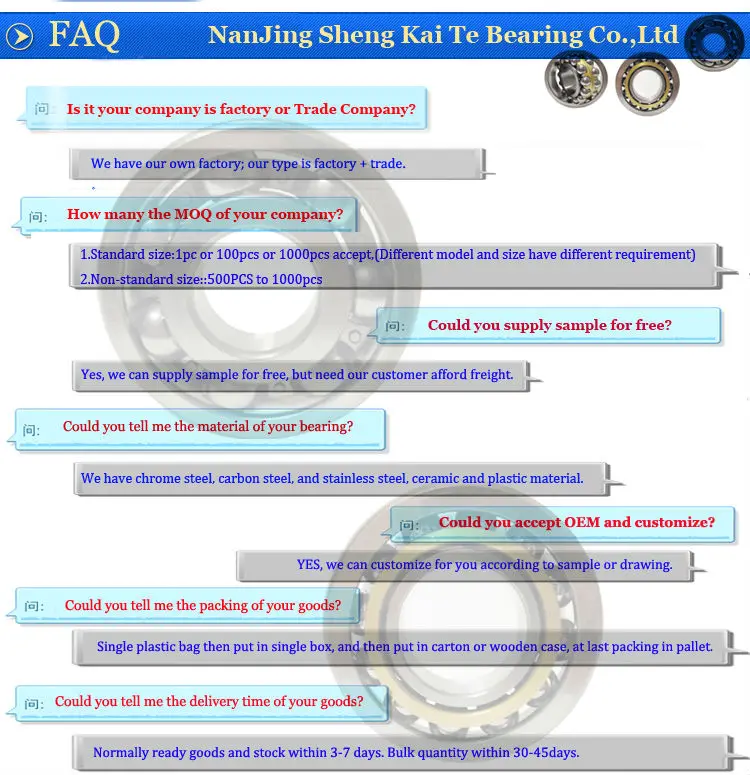

package

- Standard size:1pc or 100pcs or 1000pcs accept,(Different model and size have different requirement)

- Non-standard size::500PCS to 1000PCS

Payment:

- T/T ,L/C, Western Union,PayPal, Credit Card

Sample:

- Free sample after deposit,or sample cost at buyer's cost(refundable)

Shipping:

- For Small orders (1pc-50pc)and samll Size,we send by express UPS,DHL,FEDEX, or EMS,china post with Thracking number

- For Big quantity (1000pc-100000pc), we will ship by sea.

Before-Sales:

- Providing guidance for bearing type selection ,choosing the optimal desidn,reducin H the customer cost and esuring the operating performance of equipment

- Hlping customers design bearing applications and providing overall solutions

- Reducing operating cost for customers

In-Sales :

- Providing customers with transportation arrangements and related service

- Assisting customers in handling icoming inspection.

After-sales:

- Providing customers with trainings about bearings installation,operation and maintenance

- ENsuring the stable operation of equipment,improving

- Providing bearing failure analysis