Машина для обработки стекла сверления отверстий в

- Категории: Glass Production Machinery >>>

- Поставщик: Liaoda,(LAD),Glass,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Glass Processing Machine for Glass hole drilling

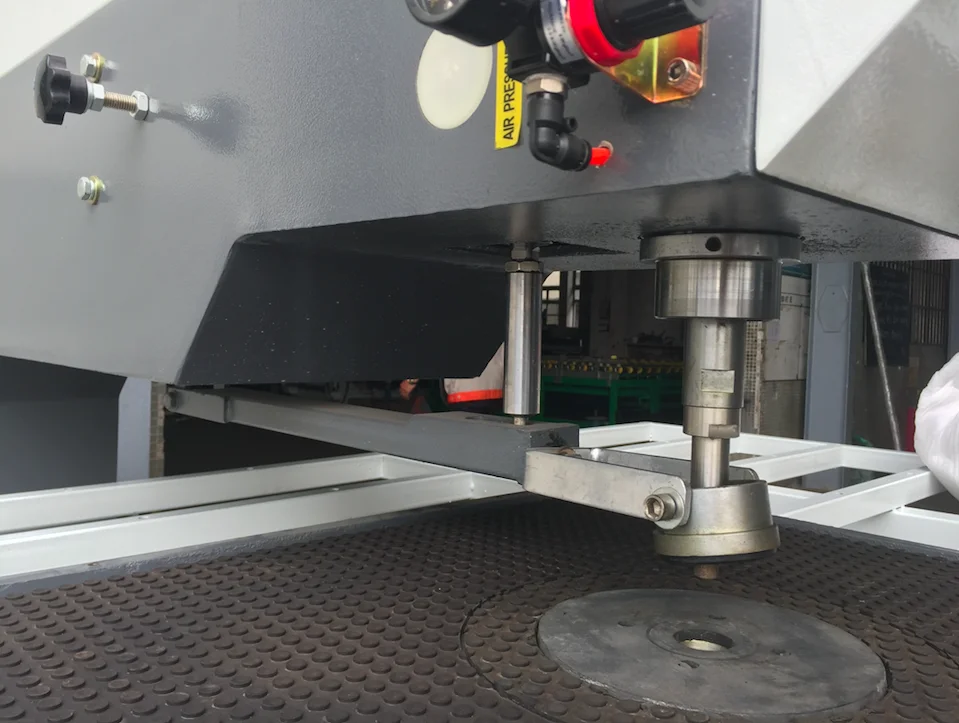

- There are two drilling spindles in this machine, one at the lower side and another upper. When the glass is put on the table, it is fixed pneumatically and the lower spindle will rise up automatically to drill from the bottom side, then the upper spindle will drill the top side of the glass and thus, the hole is drilled through.

- The cooling water runs inside the core drill so that the cooling effect is directly acted onto the glass without any loss. Tapping or chamfering can be made on the hole for particularly purpose.

- The spindle design is sophisticated such that it is strong enough for 24 hours running a day. The rigid and anticorrosive spindle enables maintenance free. Customer can designed drilling machine with extra hole diameter, glass size. Also machine is able to drill holes on water sink.

- There are semi automatic and fully automatic control modle for option

Machine Feature:

*Machine with lubricated feeder technology

*Laser positoning device

*Operation can be a single cycle, continuous cycle

*Fast drilling with high quality

*Movable coordinate location, High precision of perforation pitch

*Machine drilling hole diameter can be customized.

*Semi automatic or computer operation for options

*Easy to drill hole on glass without broken

Model Number | YD-HD-5/80 |

Distance from hole center to C-stand (mm) | 1250 |

Hole diameter(mm) | 4~200 |

Glass thickness(mm) | 3~30 |

Concentric tolerance(mm) | ±0.2 |

Compressed air consumption (IT/min) | 0.6 |

Pressure (kg/cm2) | 8 |

Power (kw) | 3.85 |

Outer dimension (mm) | 2150*2500*1750 |

Weight (kg) | 1000 |

Payment term and shipping:

- By T/T, 30% deposit, balance paid before delivery

- Machine delivery after 30days production day

- Machine loading in container or sending by LCL cargo is permit

- Shiping agent will be offer if it is required

Warranty and service:

- 1 year warranty for the machine

- Life time technical support and parts

- English version machine operation manual, machine operation video and on site service if necessary

Machine package and loading:

Wrapped by plastic bubble sheet (FCL) Plywood package (for LCL)

Machine pictures:

Our Team:

Mobile: +86 13630073630

Skype: KellyFong4

QQ: 748983414