Высокоточная ЧПУ горизонтальная машина для заточки труб с глубоким

- Категории: Расточные станки >>>

- Поставщик: Zhengzhou,Timeway,Machine,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

High Precision CNC Horizontal Deep Hole Tube Honing Machine

DHK-100 DHK-200 DHK-250

Main Outlook

Summary

Machine Summary

- The series CNC deep hole honing machine is the dedicated machine for honing and polishing of deep hole. Mainly for fine processing of the precision parts, it is an ideal deep hole processing machine with high precision and high efficiency.

- The modified version type of the machine can be designed according to the different demands. Absorbing the advanced experience home and abroad, this machine can realize accurate control of timing, positioning and quantifying in the process of production. With the development of high-performance abrasive and automated honing machine, the honing application range will get wider and wider.

Main Performances

Performance and Features

- The machine adopts the mode of workpiece fixed, honing head rotating and reciprocating. It has a wide appliation, especially for processing of non-rotary workpiece, such as hydraulic cylinder, air cylinder, square body, the workpiece with rotary shaft and flange plate, etc.

- The workpiece is fixed by V-type supporting and chain locking. The machine can be programmed to realize automatic operation, with setting up to honing time, reciprocation frequency and honing distance. It is suitable for mass production or single maintenance production. The machine selects Taiwan Delta control system with human-machine interface touch screen.

- The surface roughness is up to Ra 0.2µm and roundness is less than 0.03mm, the hole tolerance is up to IT7 or above.

Specifications List

Technical Parameters

| Specifications | Units | DHK-100 | DHK-200 | DHK-250 |

| Honing diameter range | mm | Φ25-Φ100 | Φ28-Φ200 | Φ32-Φ250 |

| Max. honing depth | mm | 1000-10000 | 1000-10000 | 1000-10000 |

| Spindle center height | mm | 220 | 350 | 350 |

| Spindle speed range of honing bar box | r/min | 50-375(Variable) | 50-350(Variable) | 50-350(Variable) |

| Workpiece clamping dia. range | mm | Φ40-Φ200 | Φ35-Φ300 | Φ50-Φ350 |

| Carriage reciprocating speed range | m/min | 1-25(Variable) | 5-20(Variable) | 5-20(Variable) |

| Cooling pump flow | L/min | 100 | 100 | 50 |

| Oil tank volume of cooling system | L | 600 | 600 | 600 |

| Honing head expansion pressure | MPa | 0.3-4(Variable) | 0.5-4(Variable) | 0.5-4(Variable) |

| Spindle motor power of honing bar box | kw | 11 | 11 | 11 |

| Reciprocating motor power | kw | 5.5(AC servo) | 4.5(AC servo) | 4.5(AC servo) |

Clamping and expansion motor power of honing head | kw | 0.75(AC servo) | 0.75(AC servo) | 0.75(AC servo) |

| Cooling pump motor power | kw | 2.2 | 2.2 | 2.2 |

Main Images

Packaging & Shipping

- Firstly packed by waterproof cloth and then in wooden case.

- Few parts may need to be taken down and be packed in wooden case.

- According to customer's different require, wo can adopt different packaging.

Whether CNC deep hole honing machine or CNC deep hole drilling and boring machine or CNC deep hole skiving roller burnishing machine, we all use the same standard Packagings.

Company Information

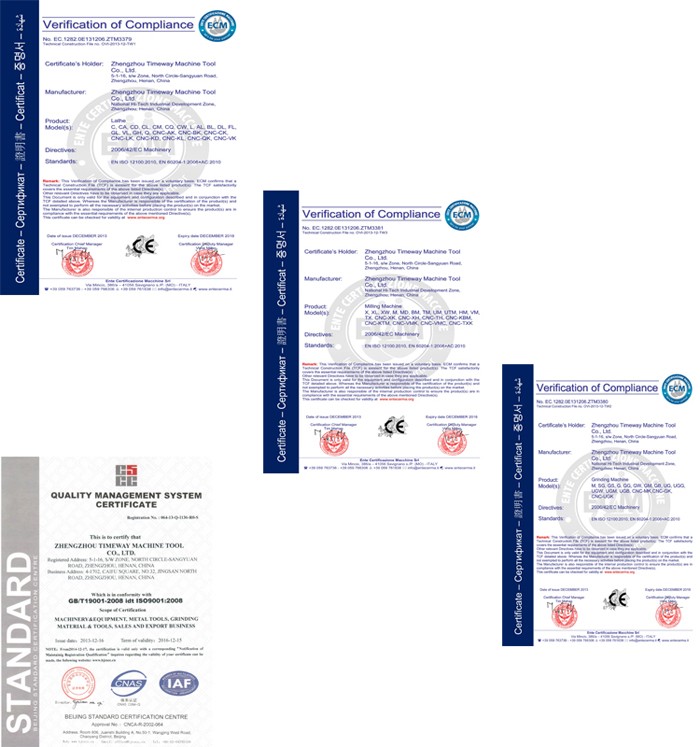

Certifications

Похожие товары

Буровая установка сверлильного станка

US $5000-$9500

Горизонтальный сверлильный и фрезерный станок

US $69000-$72000

Высокоточная машина для сверления седла клапана, serdi

US $10000-$20000