ZR262II мини-офсетная печатная машина для

- Категории: Offset Printers >>>

- Поставщик: Weifang,Zongrui,Printing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

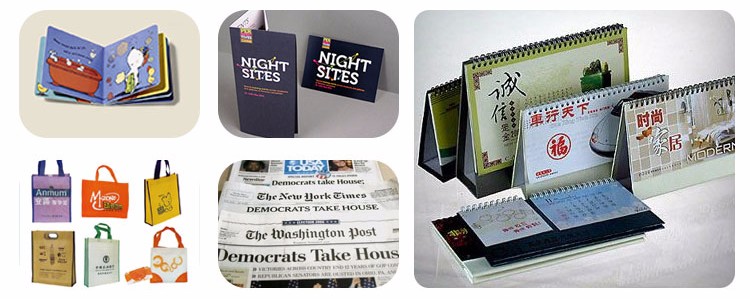

| This machine has smart structure,practicable and economical. It’s an advanced type on basic of Hamada machine. It adopts three form ink rollers and two/one form dampening roller structure. It’s a pneumatic pressing type instead of handle. It has the plate micro-adjustment function. It’s easy to operate. (Touching Screen Automatic is optional) It adopts advanced PLC programmable controller Printing products are widely available as paper cups printing press, paper printing machine, etc. |

ZR262II | ZR262II book mini Offset Printing Machine price for sale | |

| Model | ZR262II |

| Max. printing size | 605 × 440mm |

| Max. sheet size | 620 × 450mm |

| Min. sheet size | 260 x 180mm |

| Plate size | 620 × 485 × 0.15mm |

| Blanket size | 616 × 505 × 1.95mm |

| Usable paper | 45-250gsm |

| Ink roller | 16pcs (3 forme inking rollers) |

| Dampening roller | 3pcs (2 forme dampening rollers) |

| Printing speed | 2000-7000 sheets/hour |

| Power supply | Single-phase: 220v, 50Hz |

| Main motor | 1.5kw |

| Air pump motor | 0. 8kw |

| Machine dimension | 2820(L) × 1020(W) × 1460(H)mm |

| Net weight | 1350kg |

| Package dimension | 3000(L) × 1150(W) × 1650(H)mm |

| Gross weight | 1650kg |

PNEUMATIC PRESSING: Adopt pneumatic pressing cylinder for each unit making pressing automatically instead of traditional manual handles for water supply ink supply and plate cylinder pressing. |  |

| Accurate orientation: Front paper stopper of registration both side-pulled-paper stopper paper feeding horizontal registration paper feeding table slight adjustment plate cylinder registration of up/down |  |

| The latest control system: Using the most advanced control system of computer program and circuit board, that can improve production efficiency and also reduce the errors of printing. The whole machine is controlled by PLC. There are functions such as auto press, auto stop while paper jam powder jet, steps running forward and backward |  |

Double sheets detection: It can avoid the problem such as double sheets, paper overlap and non-stop |  |

| Dampening and inking separated: Dampening system is separated from inking system, which can adjust dampening and inking flexibly and content the requirement of different printing items for dampening and ink |  |

BIG CYLINDER FOR PAPER TRANSFERS: (Optional) A new type for paper transfers between two units, it can achieve the tranfers one time than old type for 2 or 3 times. The advantage:transfers more stable, ink enough time to dry. |  |

Centralized Lubricating oil supply:(Optional) use Auto system to control Lubricating oil for the important parts of machine which can improve the efficiency of machine |  |

Presented counter:(Optional) This machine adopts electromagnetic presented counter. If the quantities printing work finishes, the paper feeding stops automatically |  |

Weifang Zongrui Printing Machinery Co.,Ltd is located in the famous kite capital of the world--- Weifang. This factory was established in 2010. It is a comprehensive enterprise which collects scientific development, production management and technical service. It is the largest printing equipment production base of China. The factory covers an area of 20,000 square meters, the fixed asset 2 million dollars. The factory has advanced machinery-processing equipment, perfect quality management system and quality guarantee system. It was awarded “Shandong Famous Brand Product” by Shandong Province and awarded “Weifang Top Hundred Enterprise” by The People’s Government of Weifang and was awarded the honorary title of "Honoring Contracts and Standing By Reputation Enterprise” by Agricultural Bank of China Shandong Province branch five consecutive years. It first passed the ISO9001 quality management system certification and ensure that the quality standard products are produced every Offset press. |  |

Company Name: Weifang Zongrui Printing Machinery Co., Ltd.

Address: East Xiazhuang Ind. Zone, Beiguan Street Office, Weicheng Dist.

Weifang City, Shandong Province, China.

FAX: 86-0536-8953250 86-0536-8953251

CONTACT PERSON: Patrick Li TITLE: sales manager MOBILE: 86-18863030258

WhatsApp: 18863030258

q: WHAT’S THE PRODUCT RANGE?

A: Printing machine,such as mini offset printing machine, heavyduty offset printing machine, flexo&plate lable

printing machine,tape printing machine and some small machine like pre-press and post-press.

q: ARE YOU A MANUFACTURE?

A: Yes, we are located in weifang, shandong province which close to qingdao port.

q: HOW DOES YOUR FACTORY DO REGARDING QUALITY CONTROL?

A: Most our machine mechanical parts are processed by ourselves.So we can better controlour quality from

beginning.Electrical Part we had cooperated with good foreign brand, such as UBC, Yaskawa, Siemens, NSK,Delta, Panasonic etc.And all our machine will do running test before shipping.

q: WHAT’S THE PAPER FEED SYSTEM AND DELIVERY SYSTEM?

A: Multi-sucker universal feeder/Chain Delivers with three gripper Bars.

q: WHAT’S THE REGISTRATION?

A: Wheel-type pull side/front side.

q: WHAT’S THE DIFFERENT BETWEEN THE OFFSET PRINTING AND FLEXOGRAPHY?

A: Offset printing: Toppan printing (PS plate, resin plate).Flexography: Intaglio printing .The offset printing is

more precision than flexography.

q: WHAT’S THE THE DIFFERENT BETWEEN SATELLITE MODEL AND 2 COLOR UNIT MODEL ?

Satellite model : one imprint, two ink duct. Suitable for printing normal two color prints.

2 color unit model : two imprints. Suitable for printing high quality prints.