Энергосберегающая мини-легкая Расширенная глина комбинированная производственная

- Категории: Other Construction Material Making Machinery >>>

- Поставщик: Henan,Zhengzhou,Mining,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Energy-saving Mini Light Expanded Clay Aggregate Production Line

1. Good qulity and high capacity output.

2. Stable operation performance. Adopts negative pressure production technology.

3. The main equipment are simple structure, onvenient operation and esay for maintenance.

4. Max. efficiently usage of raw material - Limestone.

5. Lower heat consumption for unit product.

6. The usage of vertical Pre-heater can efficiently use the waste hot gas from kiln to pre-heating the limestone. This treatment will reduce the the consumption of fuel.

7. Perfect sealing of main equipment which can avoid the waste of hot gas.

8. Environmental design which can meet your local environmental rules and regulations.

9. Highly automatic control system can gurantee you high efficiency of labors.

STEP 1: RAW MATERIAL CRUSHING & PREPARATION

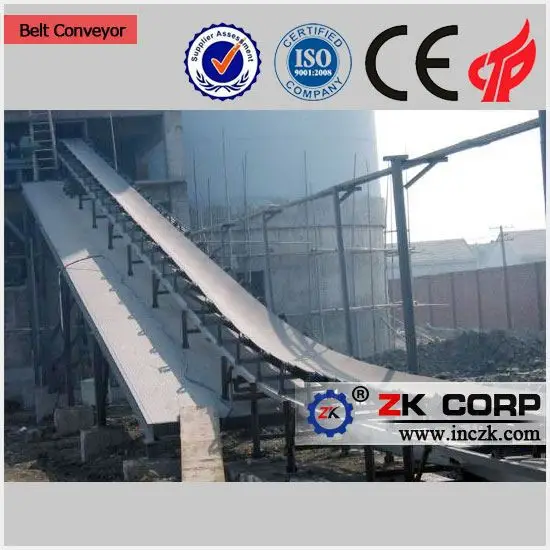

Main Equipment: CRUSHER, VIBRATION SCREEN, BELT CONVEYOR

STEP 2: CALCINATION & COOLING

ROTARY KILN

ROTARY COOLER

STEP 3: LIME GRINDING (OPTIONAL)

BALL MILL

STEP 4: LIME STORAGE & DUST COLLECTING

BUCKET ELEVATOR

BAG FILTER

Established in 1956, Henan Zhengzhou Mining Machinery Co., Ltd was a designated factory by Ministry of Machinery Industry and Henan Mechanical & Electronic Bureau to produce equipments for cement, lime and other construction material industries. Supported by Henan Metallurgical Planning & Design Institute and CHALCO Zhengzhou Research Institute, Henan Zhengzhou Mining Machinery Co., Ltd began to develop new product for calcinations of limestone and dolomite in 1988. More than 90% of the domestic Magnesium plants chose our rotary kiln to calcine their dolomite. We also supplied rotary kiln to South Korea’s first Magnesium plant-POSCO M-TECH and the biggest refractory manufacturer in Middle East-KUMAS.