Nningzheng Brand Mini Refrigerator Plate Tube

- Категории: Refrigerator & Freezer Parts >>>

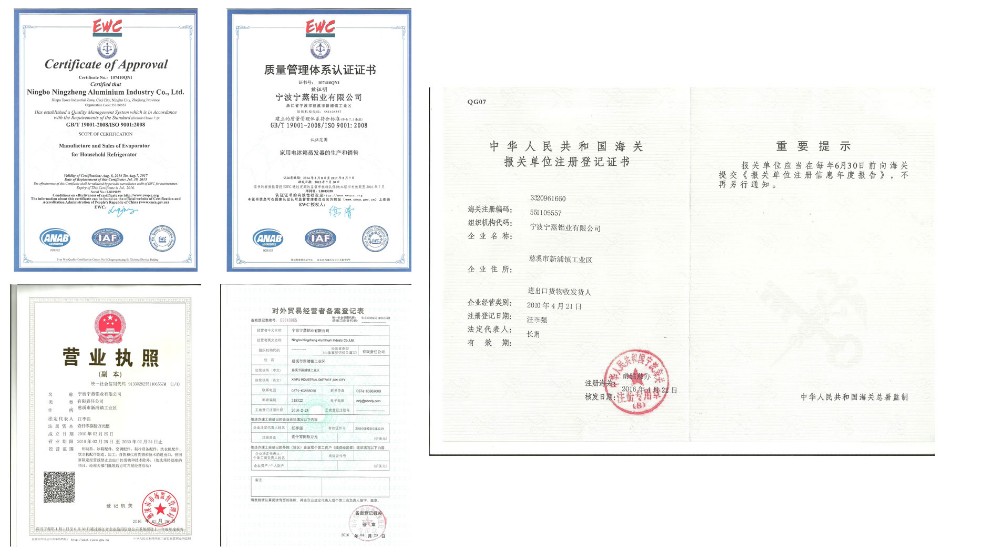

- Поставщик: Ningbo,Ningzheng,Aluminum,Industy,Co.,Ltd.,[Zhejiang,China]Ningbo

Поделиться:

Описание и отзывы

Характеристики

Nningzheng Brand Mini Refrigerator Plate Tube Evaporator

Application

Products: Aluminium Roll bond evaporator in refrigerator

Main use: Used in freezer, refrigerator,air conditioner, wine cabinet, showcase chiller etc.

Good quality, service and moderate price in the same field

Powerful production ability, quick delivery!

Raw material (Al plate) | Al plate: the thickness of finished product is 1.1-2.0mm | |||

| The thickness of raw Al plate:1.7-2.15mm | ||||

| refrigeration parts | |||

Structure | Double side roll bond evaporator | |||

| Single side roll bond evaporator | ||||

| Part single side roll bond evaporator | ||||

Key process | preparing materials – cleaning – printing – rolling – annealing - blowing up – punching –folding and sharpening –adding the capillary – assemble welding – leakage testing – cleaning and drying – coating - inspection – packing. | |||

Performance

| (1) Surface treated with powder coating to prevent corrosion | |||

| (2) Inner cleanness can meet the requirement of R134a and CFC cooling system | ||||

| (3) Can satisfy the cooling capability requirements of the designed refrigerator. | ||||

| Notation | Max dimension: width 590mm, length 2050mm. | |||

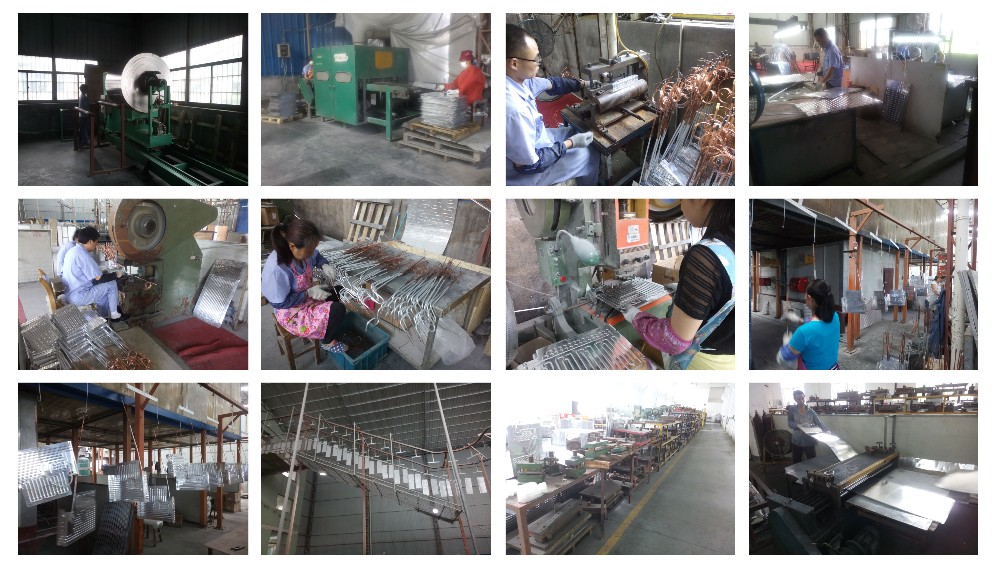

Customer visit

Normally our packing with carton/wooden case/Pearl film packaging, we can also do the packing as customers' requirements.

If you need specific packing requirements,pls let us know.

1. Original manufacturer and has been providing roll bond evaporator all over the world with innovative and high–quality products.

2. Professional team support in research ,design, production and sale to assure our customers best service .

3. Customized products and personalized services are available.

4. Strictly quality control system.

5. Quick delivery time, about 15-25 days after the payment received.

6. Fast & cheap delivery shipped by FedEx TNT, DHL, UPS, EMS...

7. Samples order is acceptable.

8. OEM /ODM machining service.

1. Do you accept products customization? Is they need mould fee?

Yes, we accept products customization.Need mould fee,because products usually need extra mould cost.But,we can return the mould fee when you reach a specific quantity.

2.How long is the normal production period for a 20-foot shippingcontainer?

According to the current productive capacity, usually needs 30 days from producing to delivery.

3.What is the type of payment?

Usually you should prepay 30% of the total amount. The balance should be pay off before we get the original B/L. L/C also is acceptable.

4.Can i keep your free sample?

Free samples are available within 1-2 pcs

5.Are you middle man or factory?

We are factory.Provide the most direct service.

6.What is the MOQ for the product and its delivery time?

It depends on which item the client making order,normally 1000 pcs