Оптовая синтетический алмаз микрон порошок для мраморного алмазного режущего

- Категории: Абразивы >>>

- Поставщик: Zhecheng,Hongxiang,Superhard,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Standard of China | Standard of International | Mesh | D50(um) | Standard of China | Standard of International | Mesh | D50(um) |

W0.25 | 0-0.25 | 60000 | 0.11~0.20 | W0.5 | 0-0.5 | 3000 | 0.2~0.3 |

W1 | 0-1 | 15000 | 0.6~0.8 | W1.5- | 0-2 | 13000 | 1 |

W1.5 | 1-2 | 12000 | 1.1~1.3 | W2.5 | 1-3 | 10000 | 1.6~1.8 |

W3 | 2-3 | 7000 | 1.9~2.1 | W3.5 | 2-4 | 6500 | 2.2~2.6 |

W3.5 | 2-4 | 6000 | 2.6~3.0 | W4 | 2-5 | 5000 | 3.1~3.4 |

W5 | 3-6 | 4000 | 3.5~4.2 | W6 | 4-6 | 3500 | 4.4~5.0 |

W7 | 4-8 | 3000 | 5.0~6.0 | W10 | 4-9 | 2500 | 6.1~6.5 |

W10 | 5-10 | 2000 | 6.5~7.3 | W10 | 6-12 | 1800 | 7.3~8.3 |

W12 | 8-12 | 1600 | 8.3~9.0 | W14 | 7-14 | 1500 | 9.1~10.5 |

W14 | 8-16 | 1300 | 10.0~12.0 | W20- | 10-20 | 1200 | 12.5~15 |

W20 | 12-22 | 1000 | 15.0~17.0 | W20+ | 15-25 | 800 | 18~20 |

W28 | 20-30 | 700 | 20~23 | W28+ | 22-36 | 600 | 23~26 |

W40- | 20-40 | 500 | 26~29 | W40 | 30-40 | 450 | 29~32 |

W40+ | 35-45 | 400 | 32~36 | W50 | 36-54 | 37~43 | |

325/400 | 320 | 43-48 | 270/325 | 280 | 48~55 | ||

230/270 | 240 | 56~64 | 200/230 | 200 | 65~73 |

Features

1. Selection of high-quality diamond as raw material, can ensure high-quality powder

2. All products through standardized management processes, process-oriented quality testing to ensure high performance and stability of the diamond

3. Anti-static dust-free workshop production, to ensure product purity 99.9%

4. Diamond powder particle size range of uniform, crystalline high agreement, basic grains accurate, easy to produce scratches when polishing

5. Product in strict accordance with ANSI B74.20-2003 R2010 standards

Monocrystalline diamond powder

Monocrystalline diamond powder select large size diamond particles as a raw material, after crushing, integer, purification, purification, separation, drying, particle size analysis, produced by technology. Monocrystalline diamond powder is yellow or off-white powder, uniform size, high strength, low impurity content.

Polycrystalline diamond powder

Polycrystalline diamond powder is using a unique method of directional blasting prepared from graphite, high detonation velocity explosive shock wave directional blasting the metal accelerated flight fly sheet, graphite sheet impact resulting polycrystalline diamond into graphite. The structure is very similar to natural diamond, formed by an unsaturated bond, having good toughness.

Diamond powder as an important raw material, can used for manufacturing soft abrasive polishing, abrasive paste, polycrystalline, drawing dies, the composite sheet and other products, processed diamond jewelry, tungsten carbide, electronic products, optical instruments.

Analysis report of particle size distribution 7-14 MICRON

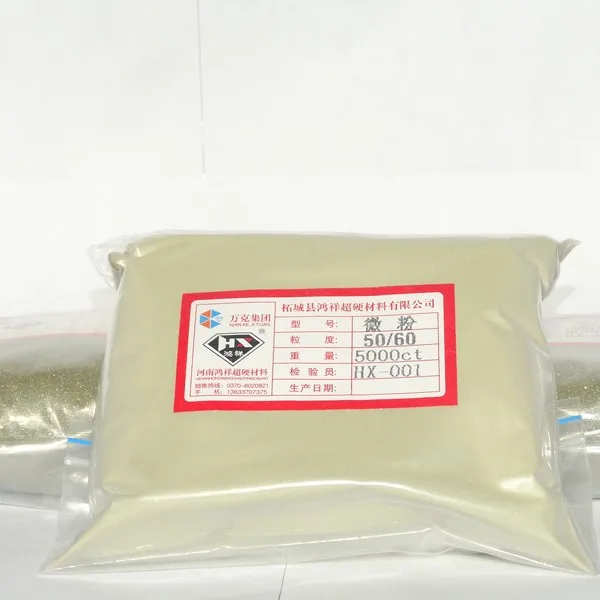

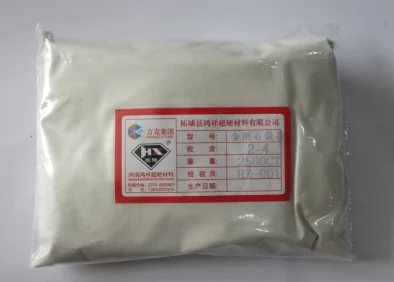

Package of diamond Powder

We will use carton package, and also can support your requirement if you need carton or other kind of package. of cause will add a little fees.

Delivery

We support express, air way, and by sea shipping.

Express like DHL, FedEx, TNT, UPS, EMS, etc.

Usually, we will arrange the shipping within 7 working days after we confirm the contract.

Established in 1990,Zhecheng Hongxiang Superhard Material Co., Ltd. is a specialized enterprise that engages in the research, production and sales of various kinds of synthetic diamond and diamond tool,glass tools,which keep ahead in Chinese market. Our target: Advanced technology is the basis of high-quality products.

Q1: What's your payment terms?

A: T/T, PayPal, Western Union, etc.

Q2: Do you accept retail order? What is the minimum order quantity?

A: Yes, we accept retail order. No MOQ. Just one piece for testing is also acceptable.

Q3: How you pack the products?

A: Carton box, plastic box, or according to your requirement.

Q4: Do you accept OEM?

A: Yes, we accept OEM. We can produce according to your drawings and samples.

Q5: What's your delivery time?

A: For stocks, within 3-5 days after payment received.

For normal order, within 5-7 days after payment received.

For mass order, within 10-15 days after payment received.

Zhecheng Hongxiang Superhard Material Co., Ltd. | ||

Tel | 0086-037186038278 | |

Fax | 0086-037186038378 | |

WhatsApp | 0086-18738113589 | |

Skype | hongxiang62 | |

QQ | 2850235769 | |

Email | hxdrill(at)hnhongxiang.com | |

Welcome to contact Nancy! | ||