Реактор непрерывного перемешивания/химический реактор/Вакуумный химический смесительный

- Категории: Реакторы >>>

- Поставщик: Guangzhou,Hundom,Machinery,Equipment,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

continuous stirred tank reactor/chemical reactor/vaccum chemical mixing reactors

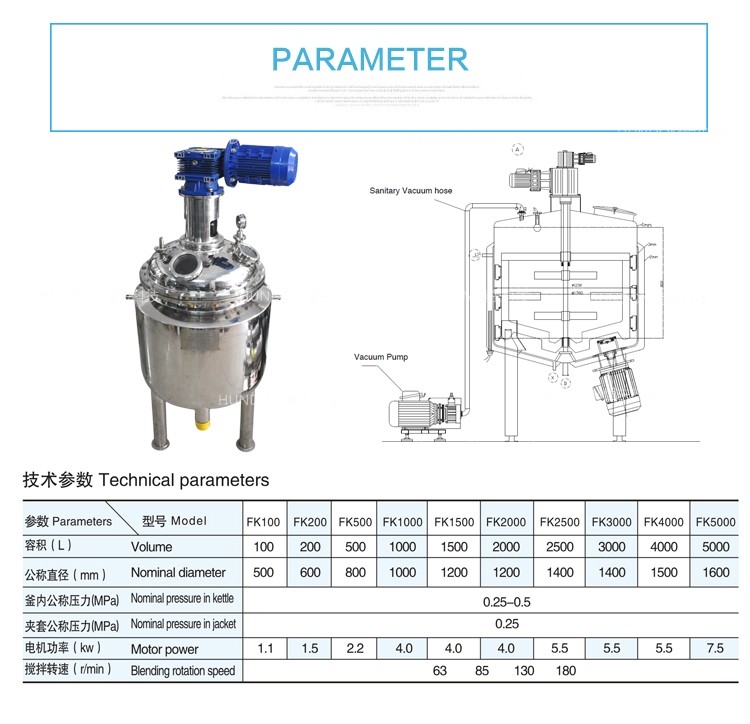

The reactor equipment is mainly used for the production chains such as hydrolysis , neutralization, crystallizationm , distillation , evaporation and storage in the industries of medicine, chemical industry, food and light industry ects . The reaction kettles are made of SUS304,SUS316L stainless steel material . The mixers are divided into anchor type , frame type , oar type and turbo type ects . The rotation mechanism can adopt cycloid pin gear reducer and stepless speed reducer . The sealing mechanism can adopt mechanical sealing . The heating and cooling can adopt jacket , semi-tube and coil structure ects . The heating methods are steam , electric heating and heat transfer oil to satisfy the technology requirements under different work environment such as anti-acid , anti high temperature , anti-abrasion and anti-corrosion . The design and manufacturing can be carried out according to the technology requirements of customers .

Specifications

| 1. | Material :SS304/SS 316(L) |

| 2. | Finish:Mirror or Matt Polish; Ra<0.4um/400mesh |

| 3. | Fully conforms to GMP requirements manufactured |

| 4. | According to technological requirement, the tank can heat and cool materials. The heating way including steam heating and electric heating. |

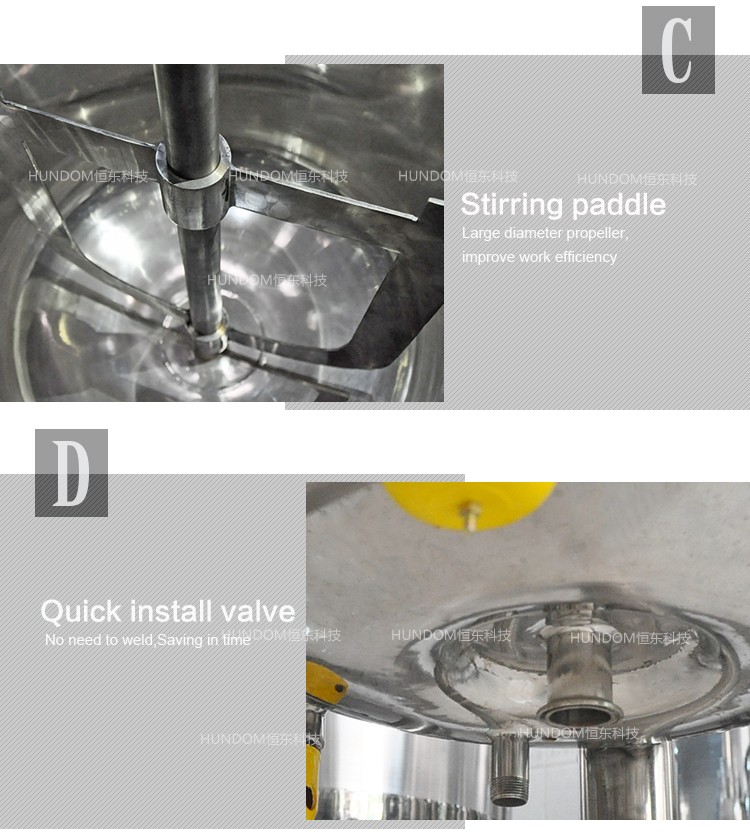

| 5. | Various forms of blending vanes are suitable for production of different types of products. |

| 6. | Easy to discharge, bottom direct discharge or by transfer pump. |

.

There are four kinds of agitators,you can choose it according to your requirement.