Jinshibao Малый завод по добыче

- Категории: Оборудование для добычи энергии и минералов >>>

- Поставщик: Jiangxi,Jinshibao,Mining,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Jaw Crusher | 150*250 | 5.5kw | 2t/h |

Hammer Mill | 400*600 | 18.5kw | 2t/h |

Belt Conveyor | / | 2.2kw | 2t/h |

Vibrating Ore Hopper | / | 0.25kw | 2t/h |

Gold Shaker | LY4500 | 1.1kw | 2t/h |

Specifications

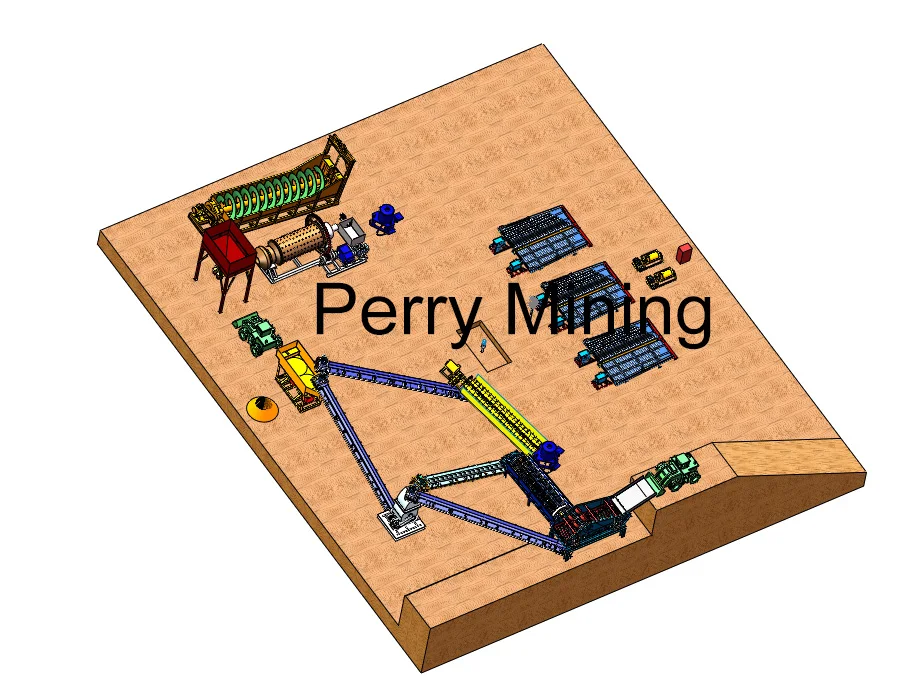

The jaw crusher, hammer mill and fine gold shaker table form the heart of the basic ore processor system. They are integrated into a turnkey unit by installing them into structural frameworks, linking them with hoppers, feeders and conveyors, and wiring them, ready for connection to a power source and water source. For long term operations, we recommend using a ball mill instead of the hammer mill to grind finer and reduce maintenance costs.

Our turnkey systems are gravity concentration plants that are easy to run and easy to maintain: simple, proven mechanics with no computers or electronics. Environmental and personnel safety issues are minimized with no use of leach chemicals or mercury.

For the small scale miner, these are the most cost effective, industrial grade processors available for continuous operation. The jaw crusher, hammer mill and fine gold shaker table form the heart of the processor. They are integrated into a turnkey unit by installing them into structural frameworks, linking them with hoppers, feeders and conveyors, and wiring them, ready for connection to a power source and water source.

Our basic turnkey ore processors utilize a cost-effective, heavy-duty hammer mill for the final pulverization just prior to the gravity shaker table. They are intended for proof-of-concept and bulk sampling programs, as well as commercial production of up to several thousand tons of ore.

However, the maintenance cost and downtime is significant with a hammer mill, so a longer term milling operation will usually choose to utilize a ball mill. The operator must consider the cost/benefit equation, as the initial cost of a ball mill is multiple times more costly than a hammer mill. However, our turnkey ore processors are designed so that the hammer mill can be directly replaced by a ball mill at a future time, with all other machinery remaining in service.