Горячая Распродажа полностью автоматическая машина для вязания металлической сетки из нержавеющей стали с защитой от электромагнитных

- Категории: Other Home Product Making Machinery >>>

- Поставщик: Tianjin,Tianyin,Tengxiang,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

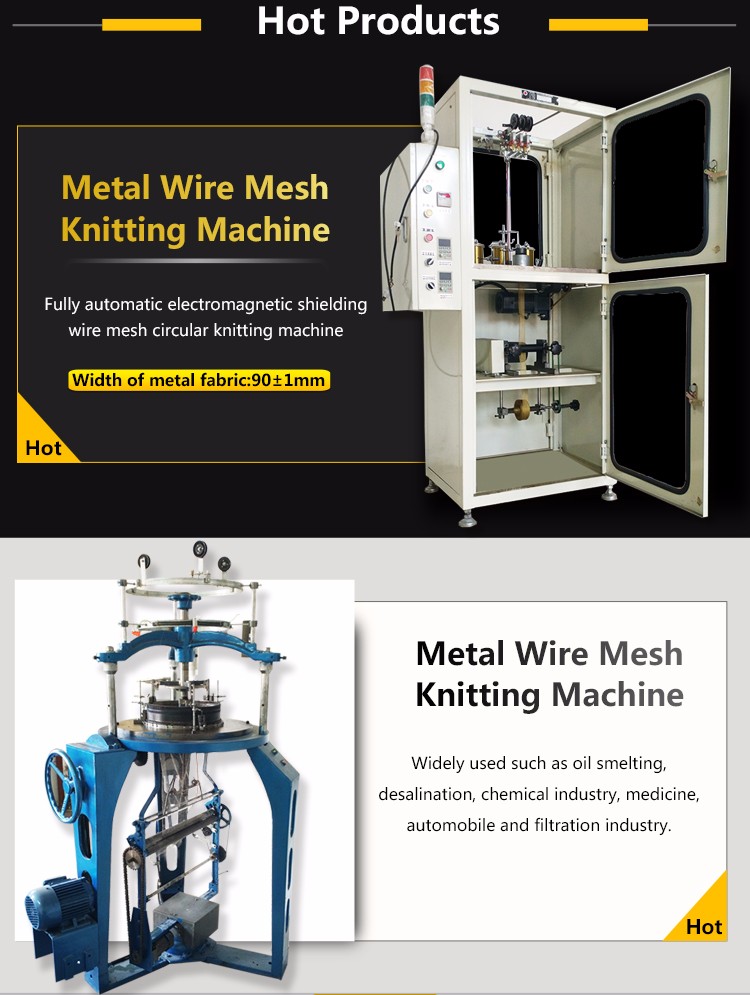

Hot Sale Full automatic stainless steel EMI shielding wire mesh knitting machine metal mesh knitted machine

Technical standard:

1. The machine is full automatic control. Two pieces metal flat wires are made by two pairs of pressure rollers. Double machine heads are knitting and coiling at the same time. Thus the production efficiency is two times.

2. Knitting cylinder speed:60-80 rev/min

Motor speed:1400 rev/min

Motor power: 1.5KW and 60KW

3. Stainless steel flattening part: Two pieces metal flat wires are rolled out synchronously. This part is equipped with frequency converter which can adjust the speed of rolling rollers and the gap of two rolling rollers. The flat wires are raw materials for knitting process.

4. The knitting part of the machine is composed of two knitting heads. Each of knitting head is equipped with double frequency speed controller to control the speed of knitting machine and drafting part respectively.

5. The knitting length can be set. The machine can shutdown and restart when it has reached the scheduled length of the mesh.

6. The machine is designed by integrated control. All control electrical appliances are places in one electrical box to operate easily.

7. The knitting part is one way and there is one piece metal flat wire.

Main technical parameters:

1. The rollers of the machine is made of alloy steel. The rollers gap is manually adjusted by screw compressing tightly. In this way, the finished flat wire size can be 0.1*0.3mm.

2. The width of knitted flat wire mesh sleeve is 50±2mm.

The needle number is 32.

Density: 280kg/m3

Material: 304 stainless steel wire

Wire size: 0.1*0.3mm

3. Knitting efficiency is 40-60 meters/hour(double machine heads). The wire flattening process capacity can meet the demand of knitting part.

4. Corrugating machine uses oblique ripple. Width of ripple is 3mm and depth of ripple is 2mm.

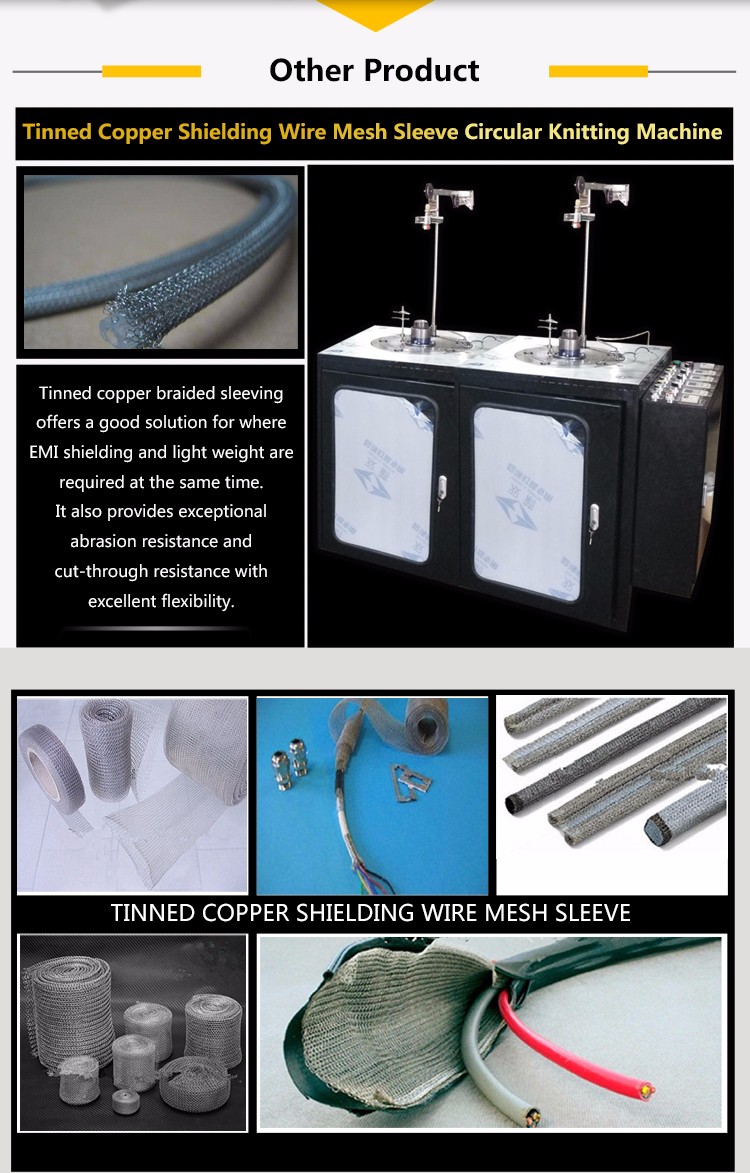

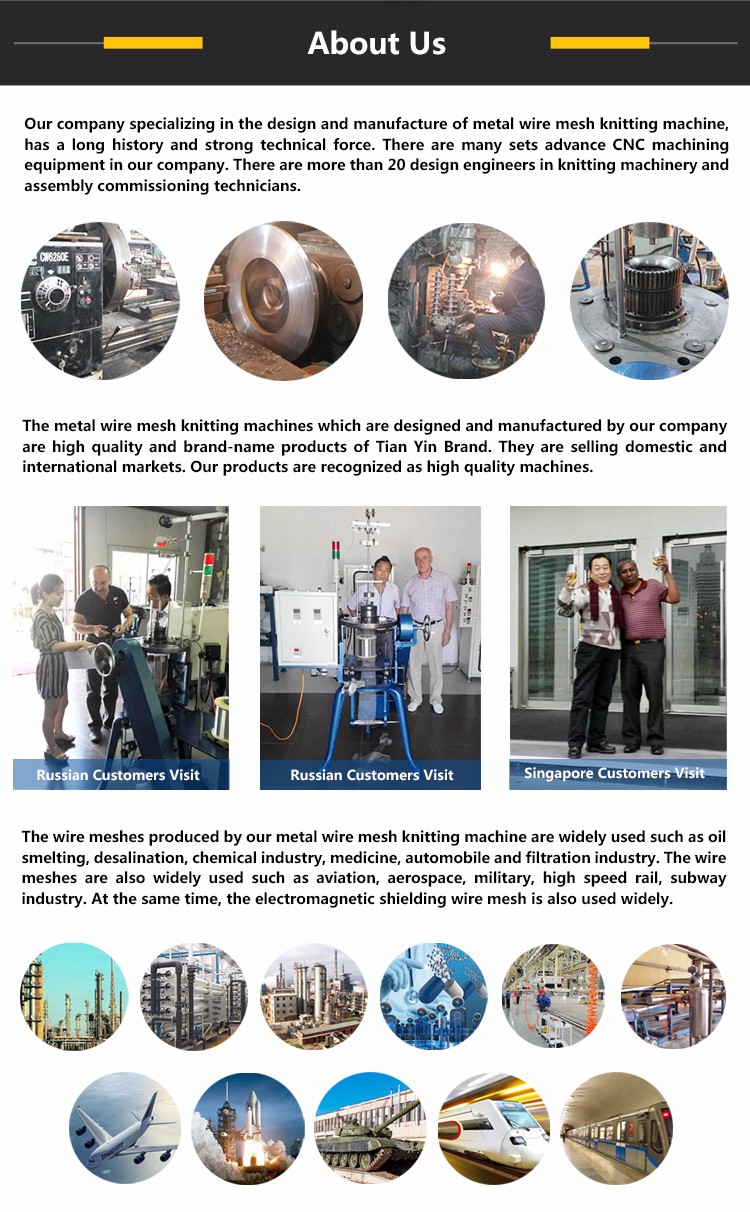

Company Information: