Производитель неочищенная система алюминиевая конструкция профиля для экструзии

- Категории: >>>

- Поставщик: Tianjin,Baiyi,Aluminum,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

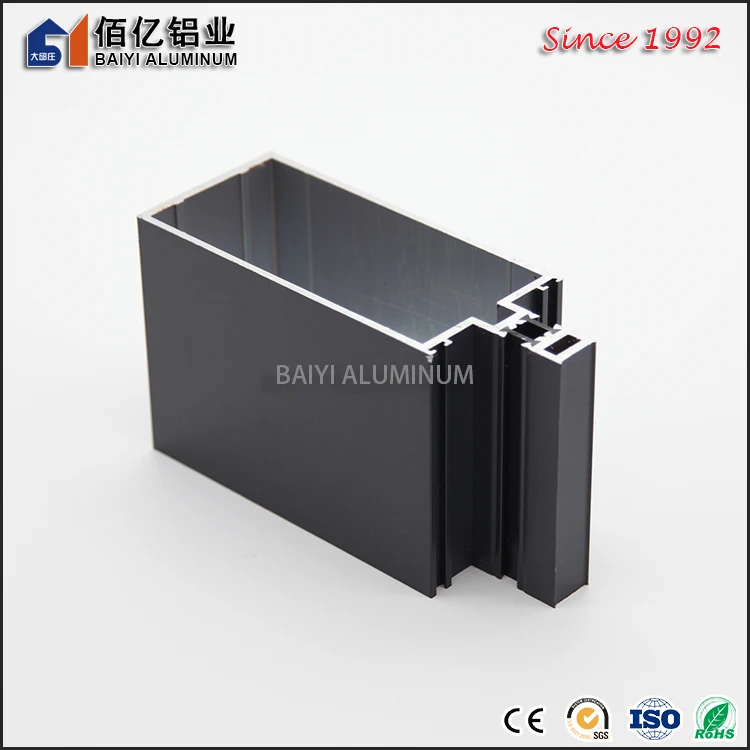

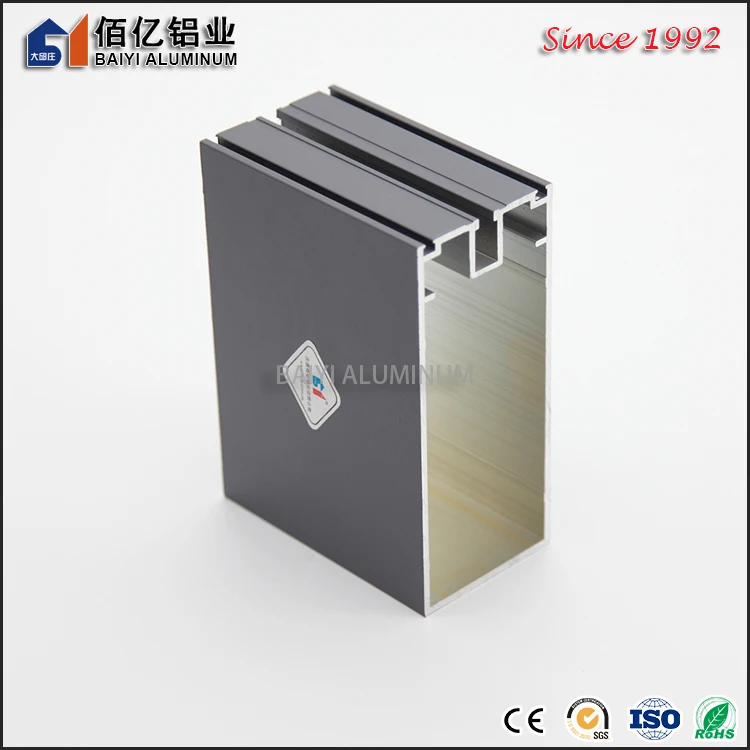

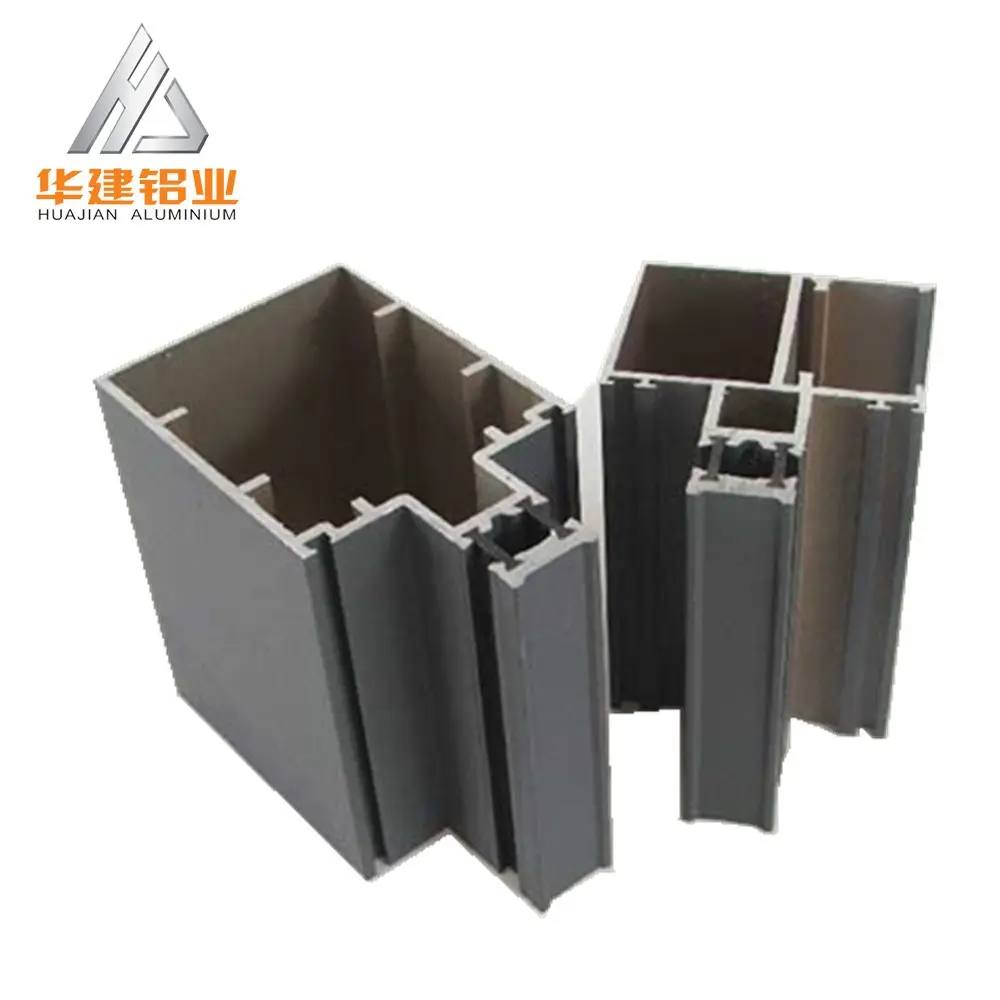

Manufacturer Unitized System Aluminum Curtain Wall Extrusion Profile Design

Manufacturer Unitized System Aluminum Curtain Wall Extrusion Profile Design use a common substructure with various width to choose, allowing a slim sightline, whilst maintaining the necessary strength and inertia requirements. Weather performance, thermal insulation, building connection, ease of fabrication and installation were the key factors that influenced the design of ours.

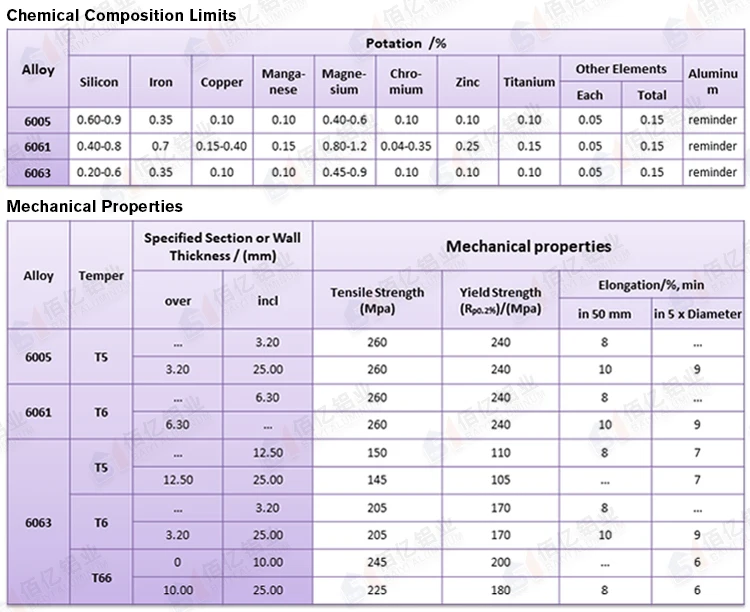

Powder Coating, Anodizing, PVDF, Wood Grain, Electrophoresis are all supported in our factory. 6063, 6061, 6005 and T5, T6, T66 are also available as material.

Curtain wall systems that apply our Alibaba Manufacturer Unitized System Aluminum Curtain Wall Extrusion Profile Design can be structured with the function of energy-saving, including frame curtain walls, and hidden frame curtain wall. Curtain wall used for exterior decoration industrial buildings and villas, and more easy cleaning, energy-saving, and good air-tightness, simple structure, easy installation, good quality procession with high technological machines, beautiful and fashion design.

The features of our Alibaba Manufacturer Unitized System Aluminum Curtain Wall Extrusion Profile Design are as below:

1. High performance in corrosion resistance, high weather resistance and excellent wear resistance;

2. Grade 6063, 6005, 6061 and temper T4/T5/T6/T66 supported;

3. On-time delivery;

4. Cutting, drilling, bending, and other machining services provided;

5. OEM, ODM acceptalbe and custom section supported;

6. Various surface treatments to choose, including powder coating, anodizing, etc.

Various packing solution supported.

We provide various kinds of packing solutions to our customers, such as Kraft Paper, Pearl Wool, Wooden Crate, Plastic, etc. Besides, we can also make packing as per customer's special requirements.

Established in 1992, located in Tianjin City, with annual 50,000 tons' aluminum products production, Baiyi Aluminum is one of the leading aluminum products manufacturers in China, we specialize in producing aluminum extrusion profiles, aluminum die casting, aluminum panels and their deep machining services.

ISO9001, RoHS, CE, approved, we regard quality as the most important thing, therefore, we have been awarded “China Top Brand”, “China Well-known Trade Mark”, “China top 10 energy-saving and Innovative enterprises”, “China top 20 enterprises in the building aluminum material” and “China top 10 enterprises in the industrial aluminum extrusion material”.

Baiyi Aluminum Capacity Introduction

| Alloy | AA 6063, 6061, 6060, 6005, etc. |

| Temper | T4/T5/T6/T66 |

| Production Capacity | 15 Extrusion Lines, up to 60,000 tons’ aluminum profiles annually |

| Extrusion Press Force | From 5MN to 30MN (500T to 3000T) |

| Surface Treatment | Powder Coating, Electrophoretic Coating, Anodizing(Matt, Sandblasting and Natrual) , PVDF Coating, Wood Grain(2D/3D supported), Brushed Metal, etc. |

| Anodizing Thickness | 10-30 micron |

| Powder Coating Thickness | 60-100 micron |

| Standard/Specification | GB, ISO, ASTM, DIN, JIS, EN, ANSI, SA, etc. |

| Length | 1-15m (for anodizing, maximum 12m available) |

| Deep Processing | Cutting, Drilling, Punching, Welding, Bending, CNC machining, etc. |

| Packing | Each profile attached with PE film, and then bundled by shrinkable water-proof plastic film. |

| MOQ | 500 KG |

| Terms of Payment | T/T or 100% irrevocable LC at sight |

| Port of Loading | Xingang Port, Qingdao Port |

| Normal Order Sequence | 1. Confirm the drawings, colors and prices; |

| 2. Pay the mould fee and we start to make moulds; | |

| 3. We send samples to you for your confirmation; | |

| 4. Make the payment of 30% deposit, start production; | |

| 5. After receiving the balance of order, delivery. |

Factory Tour

Product Category of Our Company

1. Are you a factory or trading company?

A: We are factory with OEM/ODM service.

2. Can I get some samples for free?

A: Yes, we can provide free sample, only the freight fee is paid by buyer, but if it’s for prototype, extra charge would be needed as per your design.

3. What's the lead time for your products?

A: It depends on different situations. 1) If we have moulds in stock, we can finish production within 20 days after receiving deposit. 2) If we have to make new moulds, it takes 15-18 days to finish moulds making and testing, and another 15 days to finish mass production.

4. How do I place my order?

A: Advisory → Specifications Confirmation → Solution & Quotation → P.O. Confirmation → Deposit → Mass Production → Balance → Shipment

5. What kind of payment terms do you offer?

A: T/T and L/C are acceptable.

6. Can you make my own products as per my design?

A: Yes, we can, and all the 2D and 3D digital files are supported by our Engineering Department.

7. Do you provide CNC machining and other services for further progresses?

A: Yes, we provide CNC machining, drilling, milling, punching, lathing, tapping, welding, bending, precisely cutting, surface treatment for final products, etc. until to the final products you want.