Высокотемпературный модуль из 1600 1430 циркониевого керамического

- Категории: Прочие продукты из керамического волокна >>>

- Поставщик: Jiangsu,Cera,Thermal,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

High Temperature 1600 1430 Zirconia Ceramic Fiber Module

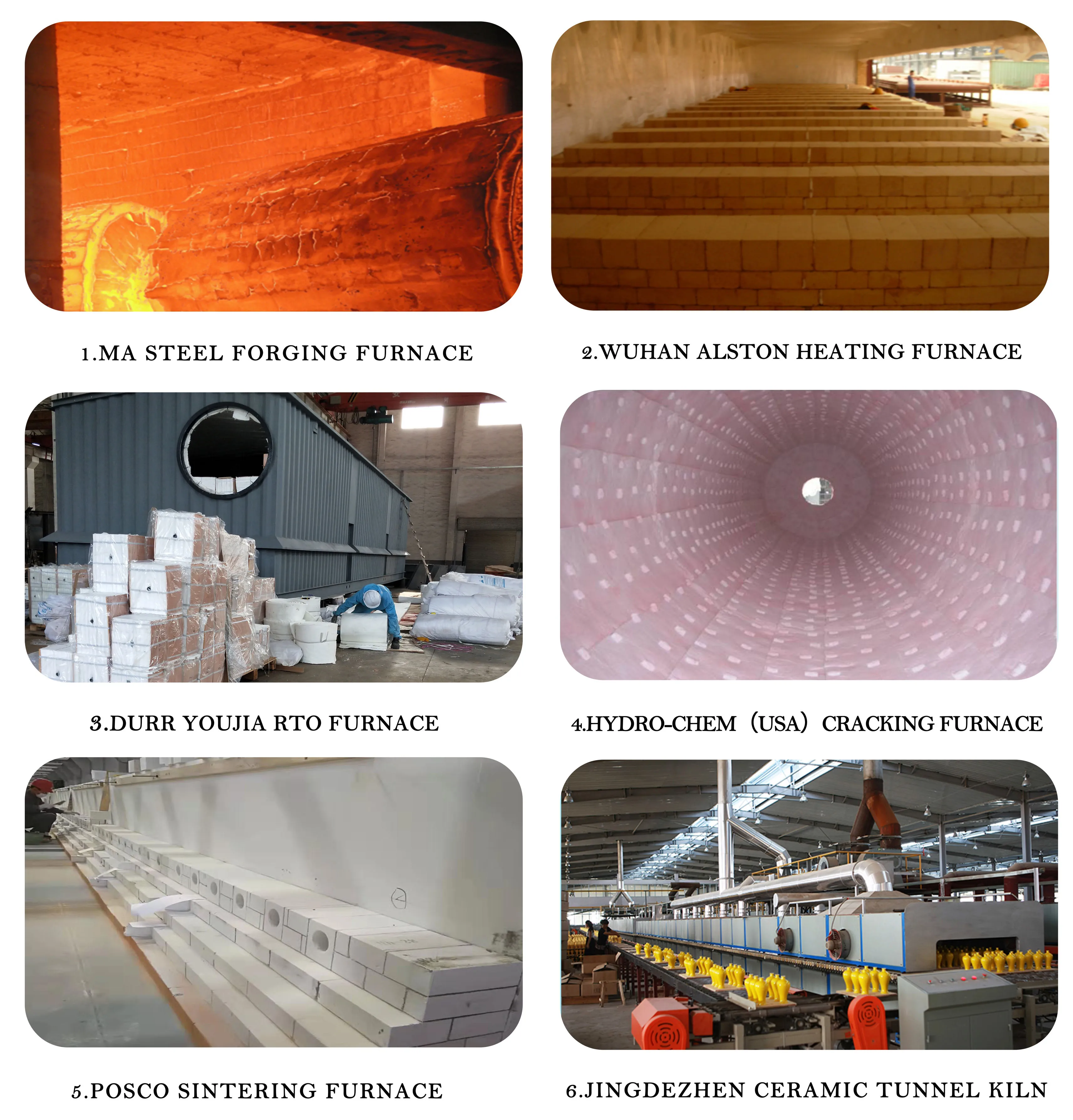

- The anchorage on the back allows for both in-line and parquet installation.

- The decompression of the blanket folds gives tightly sealed intermodular joints with both configurations

- The resilient blanket is resistant to mechanical damage

- Low thermal conductivity give high thermal efficiency

- Total resistance to thermal shock

- No drying or curing required – so available for production operation immediately after installation

- The anchor is remote form the module hot face

High Temperature 1600 1430 Zirconia Ceramic Fiber Module

Type | CT-1000 | CT-1260 | CT-1360 | CT-1430 | CT-1500 | CT-1600 |

Classification temperature oC | 1100 | 1260 | 1360 | 1430 | 1500 | 1600 |

Density(kg/m3)Density | 170,190,210 | 170,190,200 | ||||

High Temperature 1600 1430 Zirconia Ceramic Fiber Module

Jiangsu Cera Thermal Technology Co., Ltd. is formerly known as Nanjing Cera Material Technology Co., Ltd.

The main business of our company includes refractory materials production, furnace lining design and

construction of high-temperature thermal engineering, furnaces equipment, research and development

and sales of refractory material. Through years of cooperation with the British Morgan Thermal Ceramics,

we have accumulated rich experience in a good deal of engineering projects. We can provide our customers

with all kinds of high quality products, professional and customized products and engineering services

according to the actual working condition and requirements of each customer, in order to meet customers’

increasing demand of energy-saving.

Our tenet is: quality and credibility is fundamental, technology and service is the life.

- 2002 Established Nanjing Cera Material Technology Co., Ltd.

- 2005 Set up Nanjing workshop.

- 2009 Started Suzhou SLMC Thermal Insulation Materials Co., Ltd.

- 2010 Started Shandong Zibo Baoyang Refractory Fiber Co., Ltd.

- 2013 Started Thermaltec Insulation(Zhejiang)Company Limited.

- 2013 Started Jiangsu Cera Thermal Technology CO.,LTD

We obtained the quality system certification GB/T 19001-2008/ISO 9001:2008.

High-tech enterprises are under declare.

1. Thermal calculation, material selection support.

With advanced calculation software, it can calculate the heat storage loss and heat loss of

the kiln according to the temperature in the furnace, the working environment of the kiln,

and the economic selection of materials.

2. Process design.

Professional lining design team.

3. On-site guidance.

Have a rich team of on-site construction experience to provide customers with excellent

construction site guidance.

4. Installation Supervision.

Possess professional construction supervision ability, can provide professional construction

supervision service for furnace lining installation and constructio.

5. Special application consultation of thermal insulation materials.

We can provide technical support for customers and solve the difficulty of applying special

thermal insulation materials.