Высокоэффективная Закрытая охлаждающая башня для индукционных печей 24

- Категории: Cooling Tower >>>

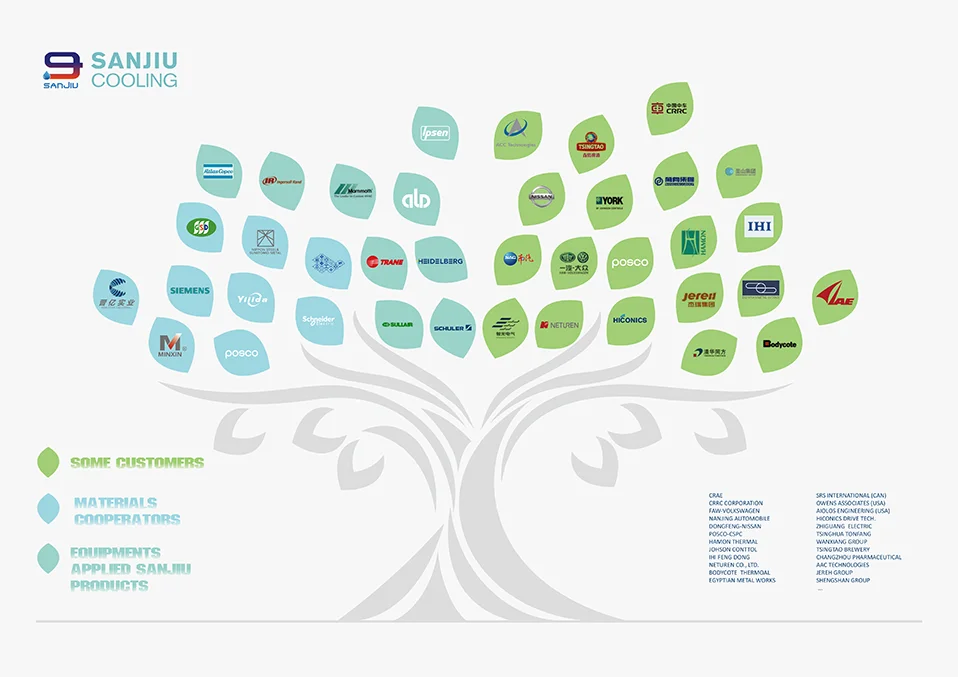

- Поставщик: Wuxi,Sanjiu,Cooling,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

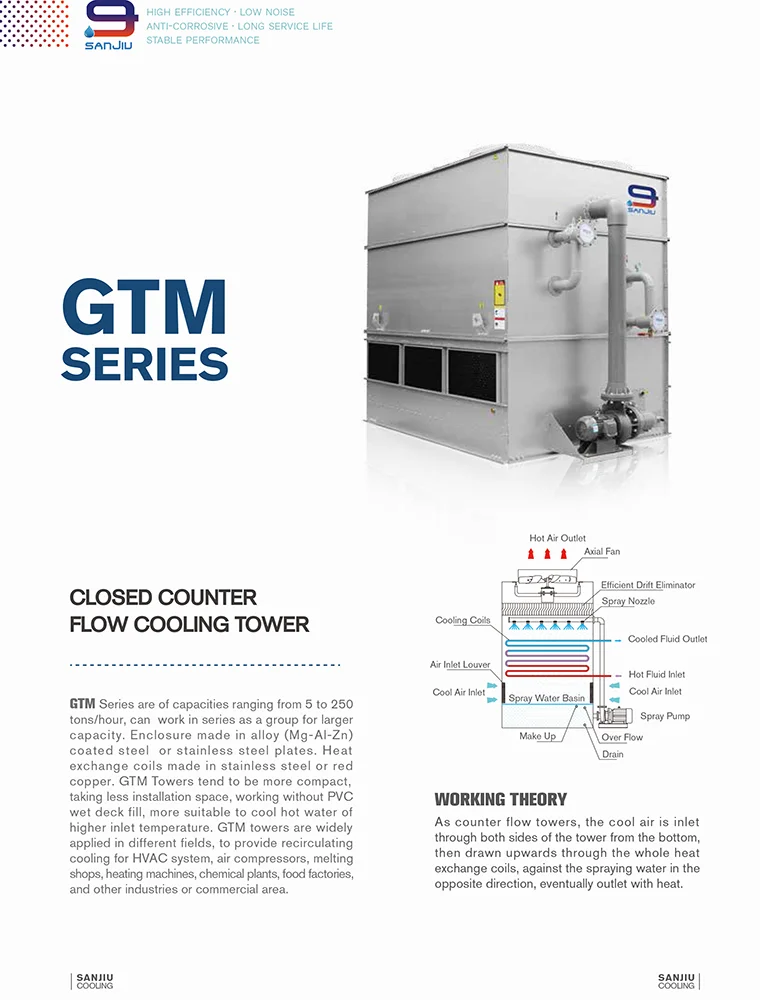

24 Ton High Efficiency Closed Cooling Tower for Induction Furnaces

Note: All the data is under the condition of 25.5℃ wet temperature.

If any change of condition,the data will change.

Model No. | GTM-20 (closed circuit) | |

Nominal Flow Rate | 24 m³/h, adjustable as different temperature | |

Cooling Range | From 65~55℃to45~35℃ | |

Water pressure | 0.32Mpa | |

Pipe diameter | Input diameter(mm) | DN65*2 |

Output diameter(mm) | DN65*2 | |

Rated Power | Fan (KW) | 0.55*2 |

Spray pump(KW) | 0.75 | |

Material of shell/tower body | Superdyma(imported from Japan) | |

Material of tupe | SUS304;Red copper | |

Installation Method | Modular Design,Easy Install | |

Closed water cooling tower shell is made in Mg-Al-Zn alloy coated steel, of "SuperDyma" series from company Nippon Steel, originally imported Japan. This special alloy coated steel is much better than galvanized steel in corrosion proof performance.

-Quick response in 12 hours

-Professional and economical cooling solution for every client

-Considerate and complete after sales service

Below information are normally required to know for selection of a most proper tower model and solution:

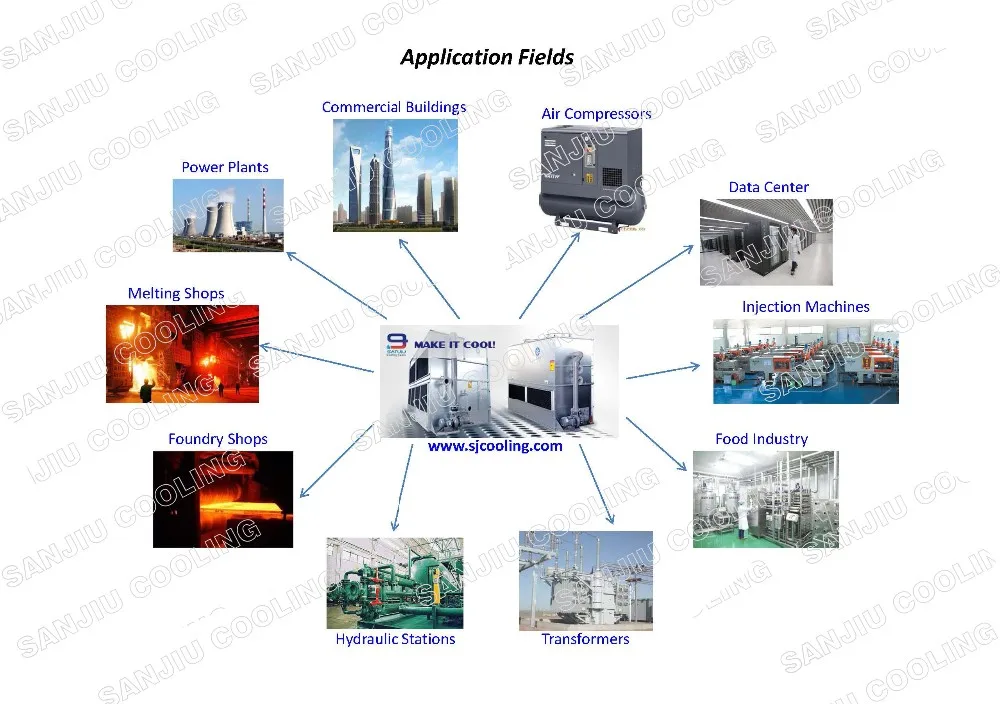

| Application: | (Explanations: Where the cooling towers will be used for? e.g. for HAVC system, Air Compressors, Melting Furnaces, etc.) | |||

| * Water Flow Rate: | m³/h | (Explanations: How many Tons of water required per hour?) | ||

| * Inlet Water Temp.: | °C | (Explanations: Temperature of hot water to be cooled) | (also descriped as "water temperature drop") | |

| * Outlet Water Temp.: | °C | (Explanations: Temperature of cooled water, usually it shall be at least 3~4 °C higher than the wet-bulb temp.) | ||

| * Wet-bulb Temp.: | °C | (Explanations: Highest wet bulb temp. of the location/area or city to install the tower is essential to know to evaluate the size of towers) | ||

| * Power Supply: | (Explanations: 380V/3 Phases is standard, which we could have in stock, but for customized towers, the delivery time could be longer) | |||

For easier discussions, 24 hours on line service available: Angela is online: skype: oasanjiu Mob./WhatsApp: 13559666650

Many thanks for your interests, and your inquires are always well attended!