50 тонн 180 кВт пластинчатый обменник испаритель с воздушным охлаждением винтовой водяной

- Категории: Industrial Chiller >>>

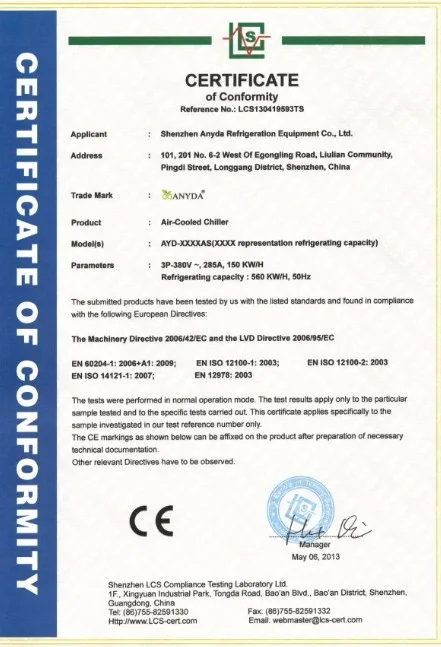

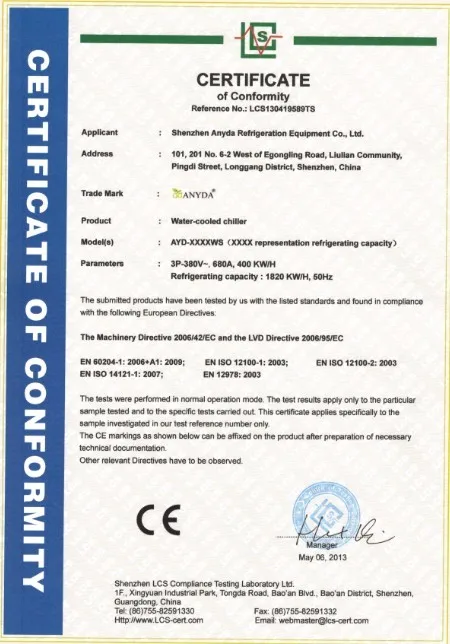

- Поставщик: Shenzhen,Anyda,Refrigeration,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description50 Ton 60 HZ Plate Exchanger Evaporator Air Cooled Screw Water Chiller

Applied Machinery: Cooling system of oil temperature, ultrasonic, high frequency machinery, injection molding machinery, blow molding machinery.

50 Ton 60 HZ Plate Exchanger Evaporator Air Cooled Screw Water Chiller

Anyda chiller machines are water-cooled type and air-cooled type. All models are equipped with compressor and pump overload protector, phase shortage and reversal alarm, anti - freeze thermostat, pressure gauge etc. They feature excellent performance and a long life span. This series of working flow is based on the basic principle of heat exchange. It is applicable to the industry that requires flow of precisely controlled chilled water, and considered as indispensable equipment for modern industry.

Applied Machinery: Cooling system of oil temperature, ultrasonic, high frequency machinery, injection molding machinery, blow molding machinery.

Air Cooled Chiller Machines Working Principle Diagram