OEM изготовленные на заказ металлические фрезерные Токарные услуги алюминиевые CNC обрабатывающие детали с лазерной

- Категории: Механическая обработка >>>

- Поставщик: Dongguan,Minghao,Precision,Molding,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Custom CNC Machining Parts of Most Materials | ||

Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) | |

Tolerance丨Surface Roughness | +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize avaiable) | |

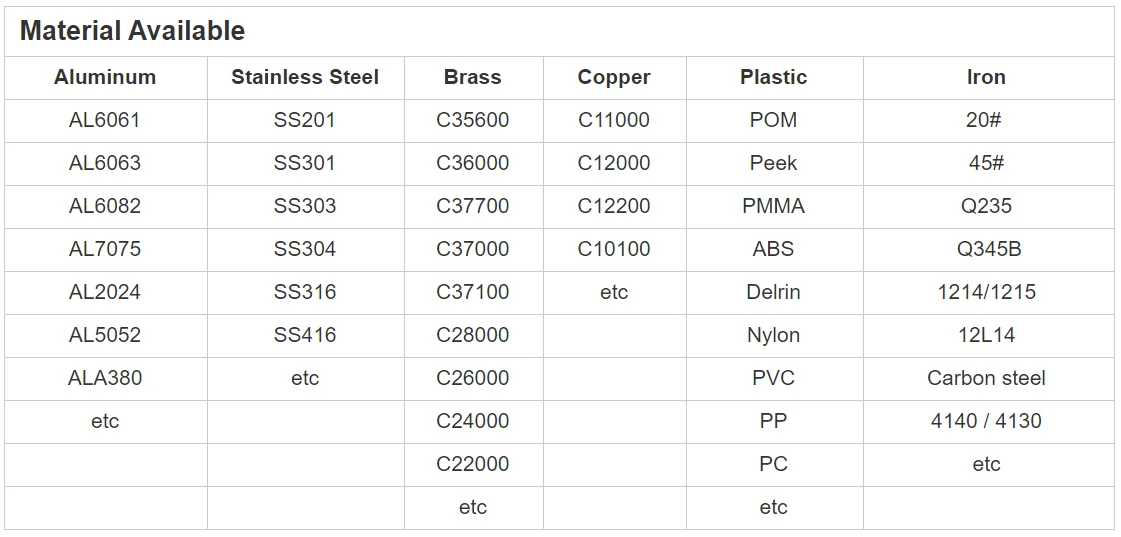

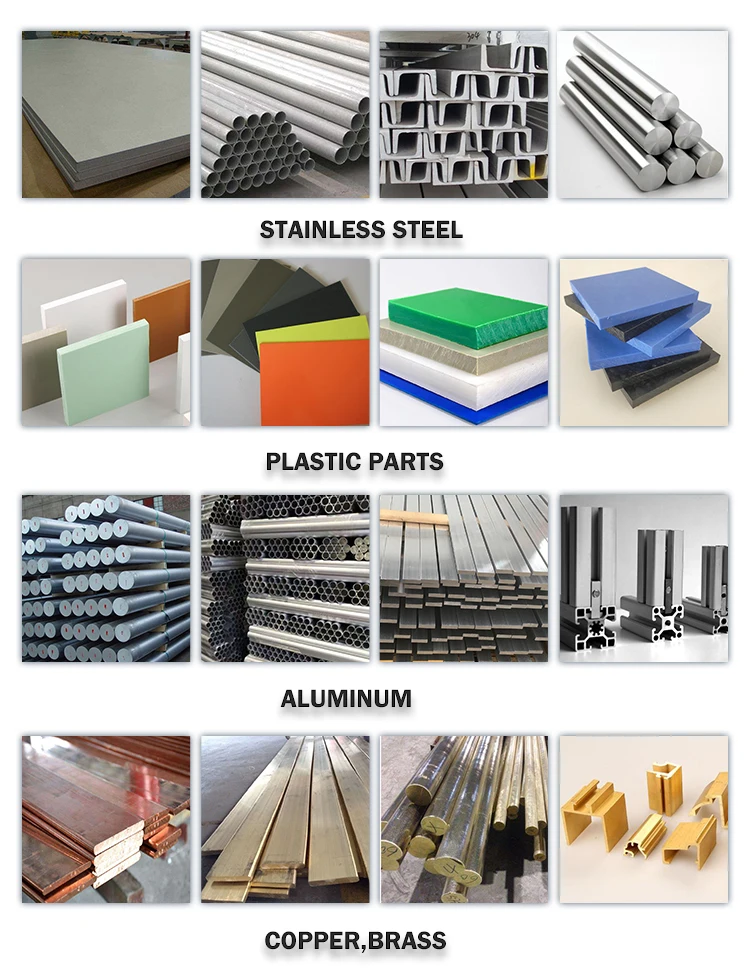

Materials Avaiable | Aluminum, Copper, Stainless Steel, Iron, PE, PVC, ABS, etc. | |

Surface Treatment | Polishing, general/hard/color oxidation, surface chamfering, tempering, etc. | |

Processing | CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment, etc. | |

Testing Equipment | CMM / Tool microscope / multi-joint arm / Automatic height gauge / Manual height gauge / Dial gauge / Roughness measurement | |

Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF | |

Our Advantages | 1.) 24 Hours Online Service & Quickly Quote / Delivery. | |

2.) 100% QC quality inspection before delivery, and can provide quality inspection form. | ||

3.) 18+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. | ||

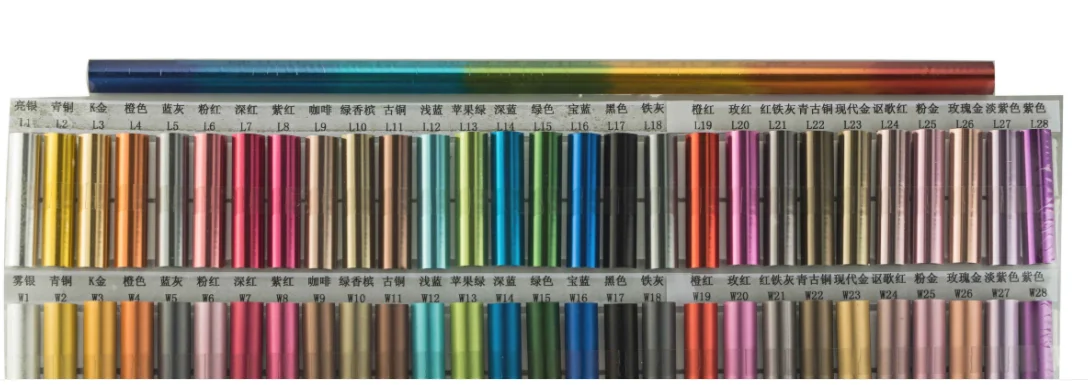

SURFACE TREATMENT

We Can Do:

<All colors of pantone>

Anodizing, hard anodized,polishing, electroplate, chrome, etched, engraving, silk print etc.

If you need anything else, please tell us >>>Go

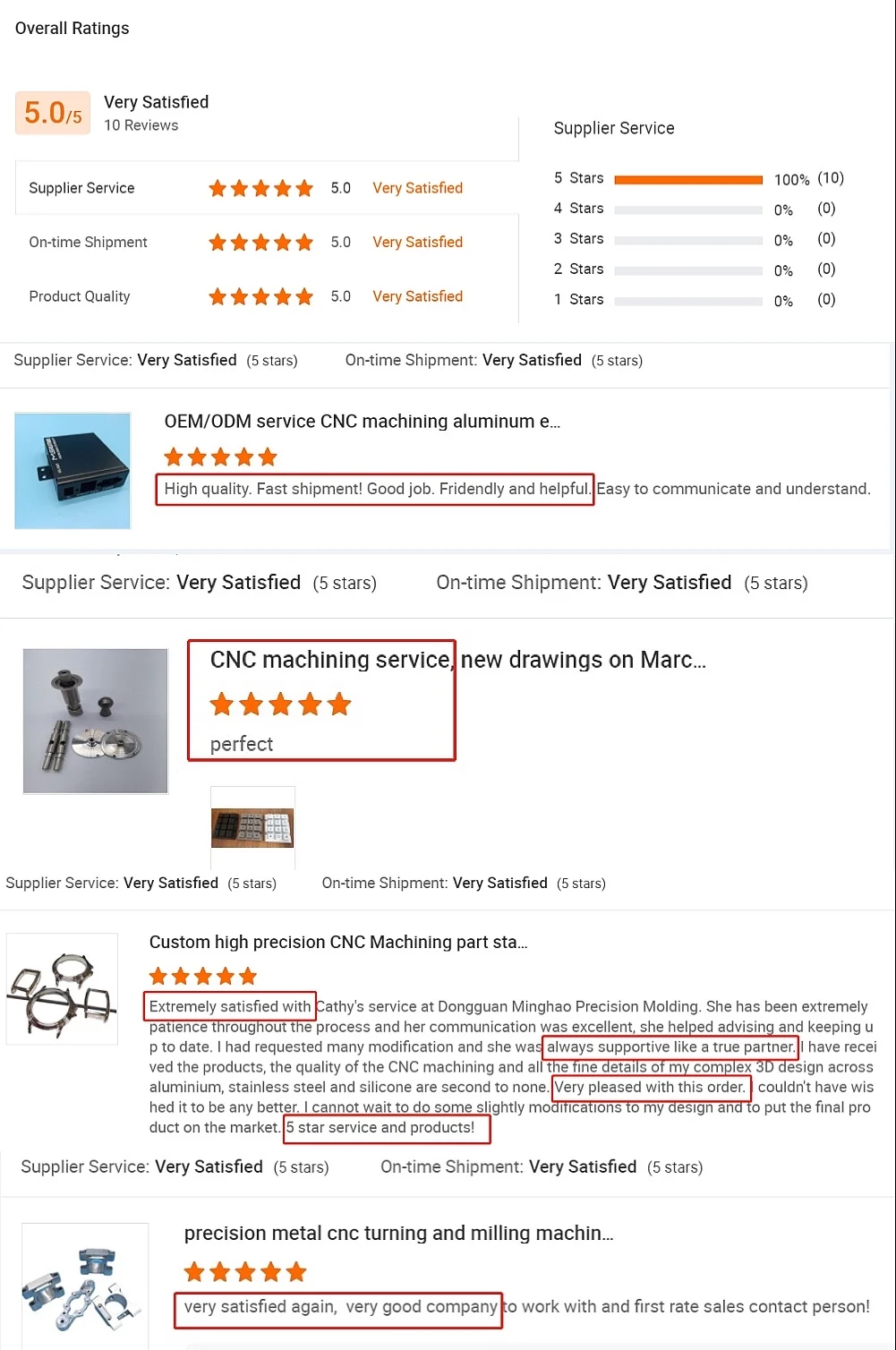

Customer Review

Company Profile

Ming Hao Rapid prototyping manufacturer is an ambitious ISO registered company, specialized in CNC machining and focusing on superior workmanship, absolute quality, cleanliness and on-time lead time. We specialize in the production of metal and plastic CNC machining and 3D printing rapid prototyping. We're a team of talented and experienced engineers, machinists and technical consultants, who commit to help solve problems relative to manufacturing precision and complex machined parts, including design,product costing, quality, assembly problems etc.

Team work: We have experienced engineers, programmers, QC, sales and management team.

Every member is firmly connected to well fulfill customers' orders. Engineers, programmers and workers share new ideas and skills together to continuously improve machining skill.Excellent communication: Sales members are fluent English speaking, proactive and have knowledge about machining, They can easily understand what you want.What makes Minghao Tech different fromother machining company is that MingHao is the label of superior quality and high efficiency.

Every member is firmly connected to well fulfill customers' orders. Engineers, programmers and workers share new ideas and skills together to continuously improve machining skill.Excellent communication: Sales members are fluent English speaking, proactive and have knowledge about machining, They can easily understand what you want.What makes Minghao Tech different fromother machining company is that MingHao is the label of superior quality and high efficiency.

We have imported many high-tech equipment during these years, for example 4 axis CNC machining center, which enables us to make complex and micro-machine precision parts faster than ever. Besides, we also have long term cooperated partners on sheet metal, stamping, injection and die casting; We can provide One-stop service to fulfill your whole project. No matter our CNC milling services, CNC turning services or other manufacturing service, we offer our customer highest precision and speed.

When receiving customers' first inquiry, we start to study their design at first time, taking them as our own projects, and suggest the best manufacturing method to bring them to life. We always provide good customer service and support customer launch new products on Medical, Aerospace, Automotive, and Consumer Electronic market soonest possible.We're flexible enough, care enough and honest enough to offer what you want. No matter what kind of your project, big or small, we do our best to provide you highest quality and competitive price parts with best service. Get us involved early, we will help you spend your money wisely!

Welcome to discuss your ideas with our technical team >>>Go

WORKSHOP

Why Choose Us

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shippingQuality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system,100% inspection and make sure the shipment with high quality products.Customer Service

Every client is served by a specialized sales for timely technical support and after-sales serviceProfessional Technical Team

80% of our technical engineers have more than 20 yeasrs of CNC machining experi-e

nce and professional technology to create the professional products.

Precision Machining

Our business content:CNC machining and the finished products,including the assembly of all kinds of hardware and plastic materials, 3D printing prototype and rapid prototyping.

Delivery On Time

Delivery-on-time of orders is our service policy. we work hard to provide the high quality products and good sakes service for every customer.

Product Packaging

Shipping

Похожие товары

Обслуживание лазерной резки дерева

US $0.80-$1.80

FR4 эпоксидная плата CNC Механическая прокладка

US $1.00-$200.00

Ролик для резки баночной маски n95 полуавтоматический роликовый нож

US $650.00-$750.00