Германия Качество качели круги поворотное

- Категории: Опорно-поворотные устройства >>>

- Поставщик: Shenyang,Leadway,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

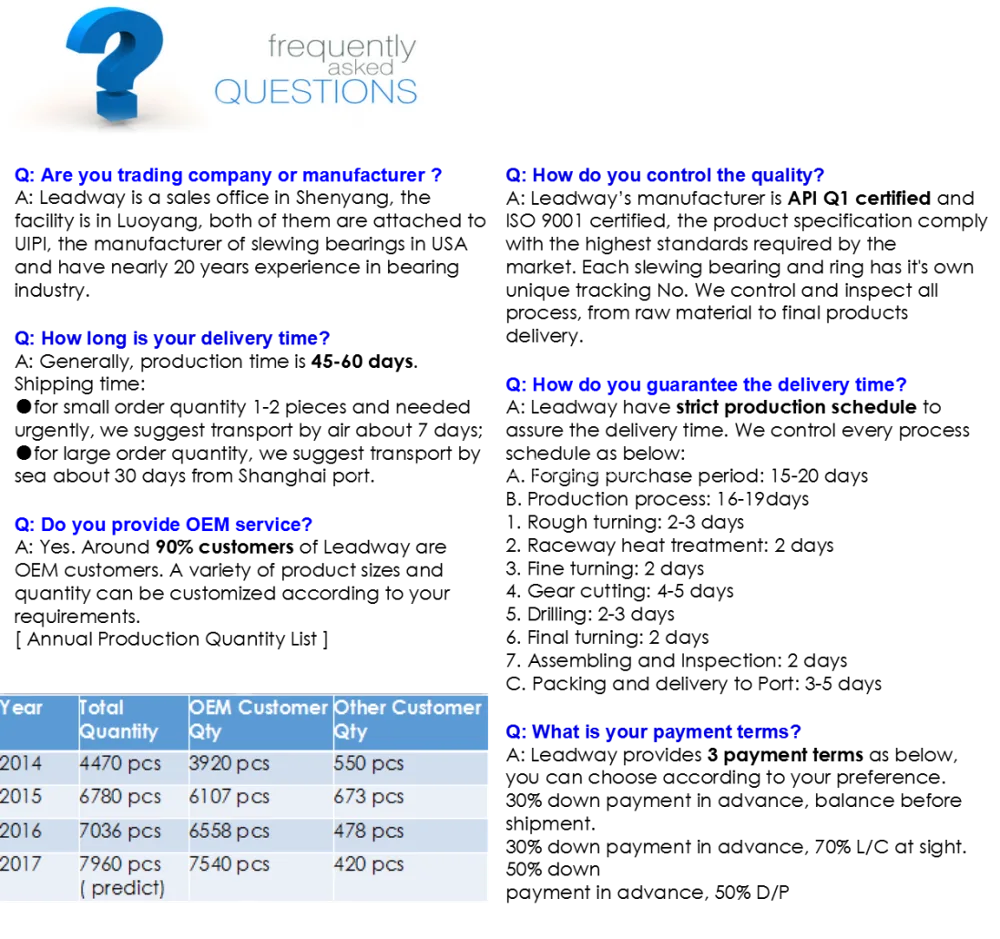

We satisfy every request of slewing bearings, slew bearings for excavators, slewing rings for earth-moving machines and slewing ring bearings for crane trucks, turntable bearings for agriculture, internal toothed, external toothed and toothless slewing bearings.

We satisfy every request of slewing bearings, slew bearings for excavators, slewing rings for earth-moving machines and slewing ring bearings for crane trucks, turntable bearings for agriculture, internal toothed, external toothed and toothless slewing bearings.

Our slewing rings can be produced with diameters between 300 and 6000 mm with crossed rollers’ sections, in single or double raw of balls, in one or three rows of rollers; and in mixed execution, rollers plus balls.

Typical applications we have supplied for include lifting, mining, logging, earth moving, medical and military applications. The slewing rings we provide give a large scale solution for high loads and controlled turning.

Our slewing rings come in many derivatives from common standard sizes through to specialist designs. All production facilities are API & ISO controlled with many external verification audits being conducted by our clients on a regualr basis.

Combining compactness, accuracy, smooth operation with relative high rigidity, together with simple mounting and operation reliability are qualities that allow use of these bearing in all industrial branches.

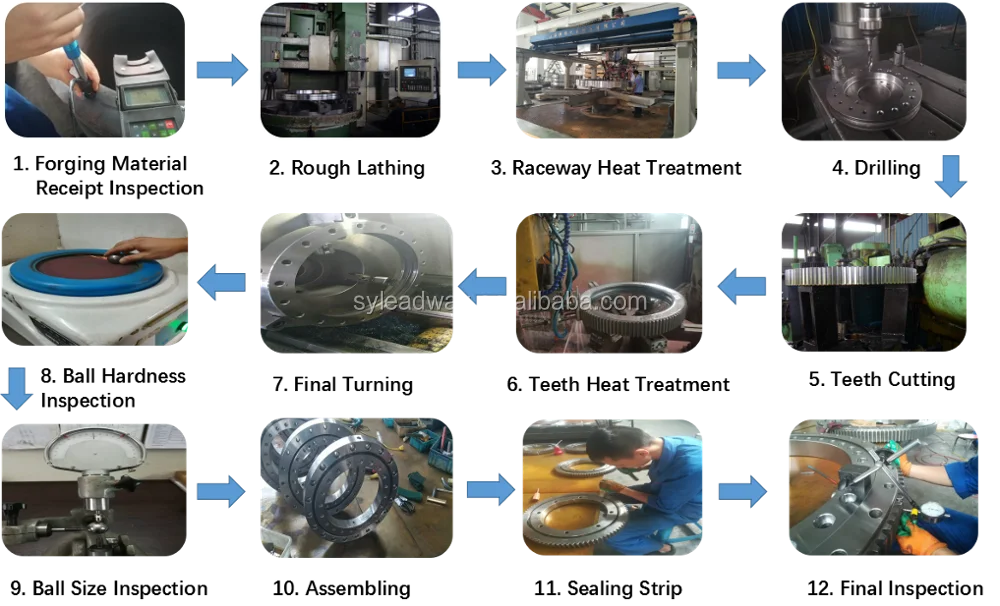

We use controlled engineering and product testing to guarantee our slewing rings for more than 10 years field life. Our slewing bearings meet the standards set by ISO 9001, CE and API Q1 certifications and provide reliable solutions. All components used in creating slewing rings are qualified to ensure the highest quality and durability. Strict inspection of each process.

When slewing ring bearings are ready for shipment, Leadway usually give a light coating of

preservative oil and packaged in a tire wrap of protective paper and a shipping container.

1st: plastic film

2nd: kraft paper

3rd: blue blet

4th: International Standard Wooden Case for by Sea or by Air

This provides adequate protection during the typical short-term storage in a protected area