Машина для холодного прессования деревянных ламинированных

- Категории: Пресс >>>

- Поставщик: Foshan,City,WEHO,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Exhibition

Wood laminate door cold press machine

Wood door cold press machine

1,Thicker steel plate make body stable and durable.

2,Precision platen working table, milling and grinding the surface, maintaining flat surface long time.

3,Easy and convenient control board operation.

4,Time control dial, set pressing time, the pressure plate will automatically rise and remind.

1,Thicker steel plate make body stable and durable.

2,Precision platen working table, milling and grinding the surface, maintaining flat surface long time.

3,Easy and convenient control board operation.

4,Time control dial, set pressing time, the pressure plate will automatically rise and remind.

PRODUCT SPECIFICATIONS

Spec /model No | MH3248-60T |

Press platen dimensions | 2500*1250 mm |

Max. total thrust | 60T |

Pressure of hydraulic system | 210kg/cm 2 |

Max.platen opening | 1000mm |

Oil cylinders size | Diameter 125mm Piston rod 90mm*2 |

Oil cylinders arrange | Straight Line |

Oil cylinders power | 5.5kw |

Overall dimension | 2900*1250*3150 mm |

Weight | 2000 kg |

Details Images

Wood laminate door cold press machine

Automatic feeding system, automatic door cold press machine production line.

Wood laminate door cold press machine

Oil cylinder for lift table, strong power.

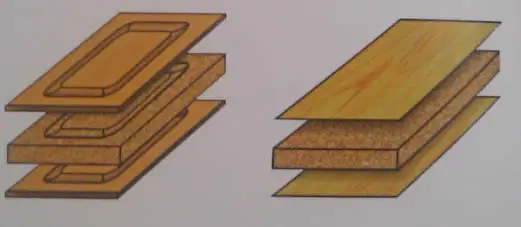

It can press various material

Easy to operation

Good for door skin press

For PVC press on MDF

Wood laminate door cold press machine

We design door production line for customers.

Machines works perfect.

Easy to operate

Long time using.

Wood laminate door cold press machine

surface pressure Posts a variety of decorative material (such

as decorative paper, decorative fabric, fireproof melamine plate,

metal foil, thin man-made and natural wood, natural veneer parquet);

as decorative paper, decorative fabric, fireproof melamine plate,

metal foil, thin man-made and natural wood, natural veneer parquet);

Wood laminate door cold press machine

cold pressing machine can also be used as a veneer drying leveling, leveling color decorative wood chips,

amorphous.

amorphous.

Wood laminate door cold press machine

Used to glue furniture plates,

building partitions, doors, (that is, within the frame and glue thin plywood) and in a variety of wood-based panel (such as

plywood, block board, MDF, particleboard)

building partitions, doors, (that is, within the frame and glue thin plywood) and in a variety of wood-based panel (such as

plywood, block board, MDF, particleboard)

Wood laminate door cold press machine

In additional to, the cold press can be applicable in density boards, shaving board, veneer boards, solid wood boards, wood glue and woodworking industry.

Features:

1.The pressure can be adjusted according to the production process, convenient and wide applicability

2.This machine is simple and reasonable structure, the operation mode is convenient, easy to learn and easy to use.

3. Strong power and high quality steel, column cylinder.

1.The pressure can be adjusted according to the production process, convenient and wide applicability

2.This machine is simple and reasonable structure, the operation mode is convenient, easy to learn and easy to use.

3. Strong power and high quality steel, column cylinder.

Packing & Delivery

Packaging | ||

Size | 3800 (L) * 1250 (W) * 2100 (D) | |

Weight | 4.3 T | |

Packaging Details | The optional package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Our Factory

Our Advantages

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design

and manufacture most of wood processing machines.

Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

and manufacture most of wood processing machines.

Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

FAQ

How to buy

1. Contact WEHO sales and provide your requirents to get best solutions2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve,

our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send

spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 00861337847781. After buying, technical supporting contact 008613326792205

1. Contact WEHO sales and provide your requirents to get best solutions2. Order confirmed, get invoice, contract from WEHO.

3. Normally, producton started against TT by 30% deposit.

4. After one week, WEHO sales inform you production state and delivery date.

5. Order finished, WEHO sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve,

our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for weho machines, including find problems, send

spart parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact Whatsapp 00861337847781. After buying, technical supporting contact 008613326792205

Похожие товары

Furniture Door Vacuum Membrane Press Woodworking Machine

US $750.00-$4450

Продукт на заказ, полировка пластин SUS

US $800.00-$1200

Машина для горячего прессования пресс машина плита

US $800.00-$1200