Многоразовые пеной из терполимера тфэ гфп и перфторалкилвинилэфира машина прессованные полиэтиленовые пенные нудл для

- Категории: Foam Machinery >>>

- Поставщик: Laizhou,Jinlida,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

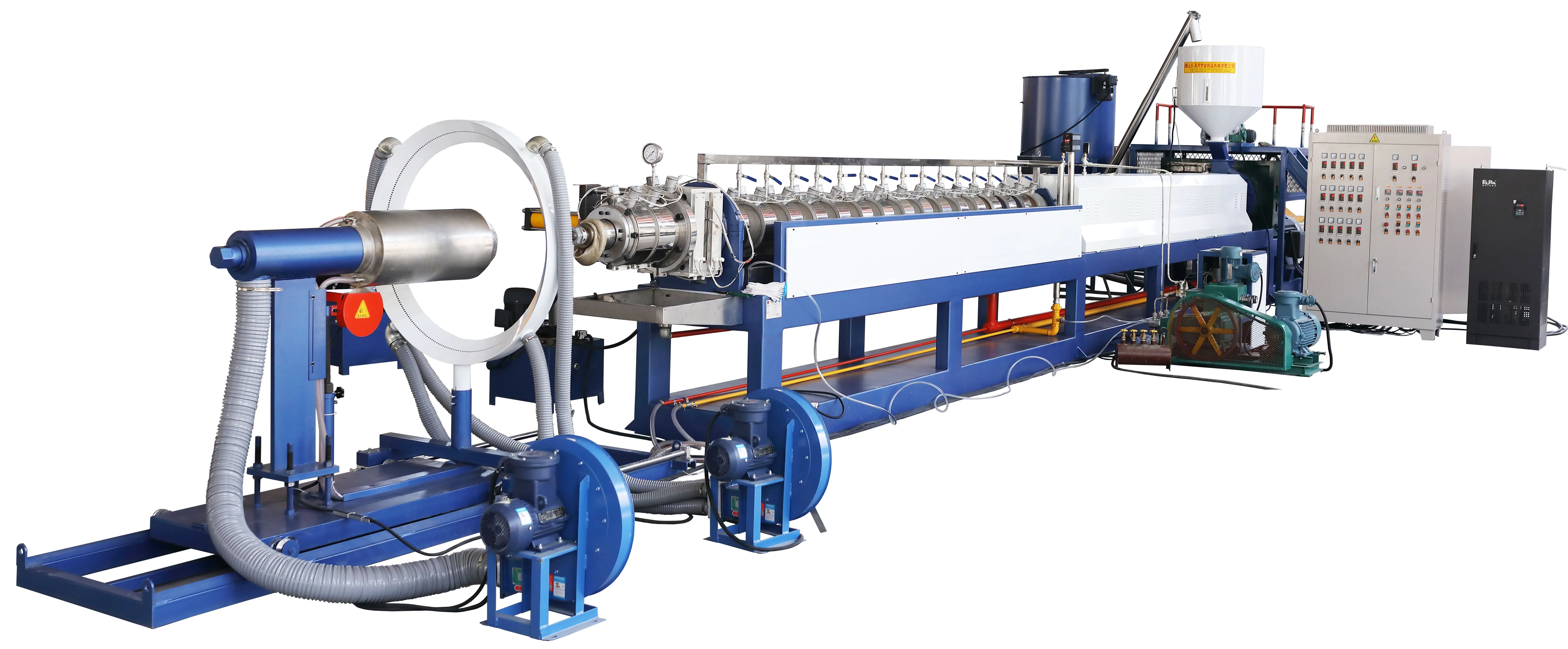

epe foam board making machien

Main Parameters

Item | Unit | Parameter |

|---|---|---|

Model |

| JLD-EFP-120 |

Diameter of screw | mm | 120 |

Applicable material |

| LDPE |

Thickness of product | mm | 0.5-7 |

Max. Product width | mm | 900-2000 |

Output | kg/h | 120-180 |

Screw speed | m/min | 5-50 |

Power supply |

| three phase 380v/50Hz |

Machine Rated power | kw | 115 |

Parts of the machine

A Feeding unit

B Extruder

C Extruder head and mold

D Blowing agent injection unit

E Anti-shrinkage agent injection unit

F Cooling,conveying, hauling and winding machine

G Rewinding device

H Control cabinet

Application area of the EPE product

EPE is widely used in packaging, such as hardware products, toys, fruits, leather shoes, internal packaging, daily necessities and other products packaging.

After adding color antistatic agent and flame retardant, it shows its excellent performance.

EPE is also widely used in the industrial production of sound insulation, thermal insulation materials, agricultural insulation materials, aquaculture floating equipment, protective pads for sporting goods, water operations lifesaving equipment, family, hotel floor decoration, liner and so on.

Its pipes are widely used in air conditioning, buggies, children's toys, furniture, plumbing ventilation and other industries.

nes design epe foam board making machien mainly used to produce EPE sheet, after thawing the LDPE resin mixed with butane gas,

talcum powder, anti-shrinkage agents and other agents through the extruder and foaming from the die and die lip, then after setting ring fixed to the sheet size,

the final product take-up by the roller.

Application of high density automatic floor dampproof mat production line

Click here, sent us inquiry. We can sent you our price list for your reference first.

More details of durable plastic polystyrene ceiling machine

Export standard packig for durable plastic polystyrene ceiling machine

1.Use the PE foam sheet pack every part to make sure every part can not damage

2.Easy rust parts coating anti-rust oil then laminate with strech film

3.Use wood fix every part in container to make sure them can not move

4. Plastic film suitable for shipping

5.As per customer's request

Q:Why I choose your company?

a, We are China Leading foam machine Manufacturer.

b, our company have made foam machine about 14 years with strong experience and advanced technics

c, Best Quality & Best Service with Competitive price.

d, 100% inspection Before Shipment. And we have got CE certificate100%

e, we have Professional technical team, will supply 24 hours service

f, our machine have good quality, 1 year guarantee

Q: Where is your factory located? How can I visit there?

A: Our factory is located in LaiZhou city, Shandong province, you can fly to Yantai Laishan Airport.When you confirm the flight No. and time, please tell me then we will pick you up at Airport

Q :Are you a factory or a trade company ?

A: We are manufacturer ,direct supplier from China.

Laizhou Jinlida Machinery Co., Ltd was established in 2003.

Our company is a collection of scientific research and development, manufacturing sales, technical services as one of the technology-based private enterprises.

Up to now, our company has been focusing on the production of EPE materials manufacturing machines and machines related to the further processing of EPE materials.

Our machines sell well at home and abroad.We have received good comments from customers all over the world.

Our company attaches great importance to customer satisfaction.We will continue to improve the quality of our products and services.