Электрический автобус skd ckd кузов рама сварки сборки jig приспособление

- Категории: Other Welding Equipment >>>

- Поставщик: Zhengzhou,Duoyuan,Automobile,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Body Frame Assembly Machine auto body frame machine

Vehicle Frame Assembly Equipment

The frame assembly equipment is in the production process commonly used by coach manufacturers for batch production. It is also the main way to improve product quality and production efficiency. Through years of research and development, our company has developed the frame assembly equipment suitable for different coach manufacturers. Together with various types of lifts, the equipment can realize high-precision, high-quality and convenient frame assembly.

As the special large equipment for body assembly, assembly equipment is also a kind of necessary equipment for volume production and line production of passenger vehicles. The current body assembly equipment is able to satisfy the production of vehicle in 6 m~13.7 m length and 1.8 m~2.55 m width at present by adjusting the position of positioning points within the range to adapt to the positioning demands of different buses types. Assembly equipment can be used if the body height, length and diagonal of gantry and large gantry satisfy the scope of tolerance and equipment are appraised by the time of model change for assembling different types with assembly equipment. Therefore, the precision of body to be assembled, model change time, equipment stability and type adaptability must be stressed for assembly equipment.

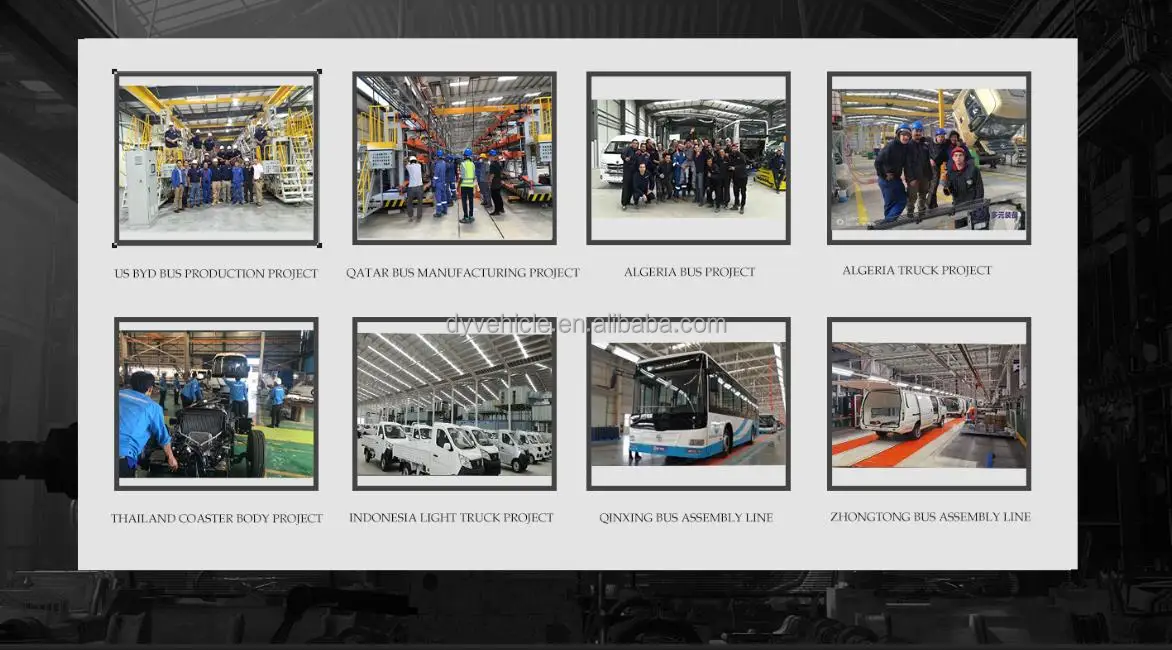

The figure above, made by Duoyuan Equipment, refers to a kind of bus body frame assembly equipment used by main domestic passenger vehicle manufacturers at present, such as Yutong Bus, Zhongtong Bus, BYD Ebus in Los Angeles. All positioning devices of the equipment are set with independent adjustable servo control, which contributes to universality. The models produced by passenger vehicle manufacturers can be assembled seamlessly; all vehicle models can be recovered. The positioning control mode controlled by independent servo control removes the disadvantage of the assembly equipment of previous generations.

Example: Yutong Bus R-Line Equipment Parameters | ||||||

Min. width after Mid Beam Closed | 1780 | Max. width after Mid Beam Opened | 3200 | |||

Min Dist btw mid and bot beam | 0 | Max Dist btw mid and bot beam | 200 | |||

Min Dist btw top beam and bot beam | 550 | Max Dist btw top beam and bot beam | 1500 | |||

Top beam vertical positioning dist | 0~1400 | Bottom beam vertical positioning dist | 0~1400 | |||

Horizontal positioning dist btw top beam and mid beam | 0~200 | Horizontal positioning dist btw mid beam and bot beam | 0~200 | |||

Main Features

1) Fast adjustment and model change, high positioning precision, strong universality and high performance ratio

2) Duoyuan's equipment relying on mature technologies, such as servo, PLC, automatic production equipments are employed to meet the demand for automatic operation such as vehicle conveying, material transfer and model switching.

3) Can satisfy the manufacturing demands of different types, such as single-deck bus, double-deck bus, or school-bus.

Changeable plug auto body frame machine

Model: DYHZ-A

Brand: Duoyuan

The figure refers to a kind of assembly equipment being used by one manufacturer. Consisting of equipment host, propelling plant and electrical control, the equipment can satisfy the manufacturing of different models by changing plug. The large radian of top roof of some vehicles leads to large plug size, which finally results in the heavy labor strength of changing model positioning, long change time and more variety of plugs.

Model: DYHZ-B

Brand: Duoyuan

Such equipment has a positioning device which consists of three slides, each of which is provided with overall mechanical adjustment mode, fast and reliable. It was advantageous on the market in 2012-2015 and still dominates the market of the assembly equipment used by passenger vehicle manufacturers. Currently, BYD e-bus factory in Los Angles is using such equipment, positively meeting the production capacity of 500 buses per year.

Universal PLC Control Adjustable Assembly Equipment Body Frame Assembly Machine auto body frame machine

Model: DYHZ-C

Brand: Duoyuan

The most standout equipment, All positioning devices are set with independent adjustable servo control, which contributes to universality.The models produced by passenger vehicle manufacturers can be assembled seamlessly; all bus models can be recovered.

ABOUT DUDOYUAN

Duoyuan automobile equipment Zhengzhou, founded in March 1998, is a professional technology-based automotive equipment, welding fixtures, wire body conveying equipment, rolling equipment and a variety of related customized automation equipment development, design, manufacturing and service business.

Founded early, along with the vigorous development of Yutong Bus and growing, well-designed for the non-standard equipment, meet Yutong's rising productivity demands, and received consentaneous reputation. At the moment, this has been laid a solid foundation for Duoyuan Equipment to be the first brand of the China's automobile equipment. After years of development, technical accumulation and personnel cultivation, we have developed our passenger vehicle business quickly in recent years. Covering an area over 30,000 m2 (including building area of more than 10,000 m2), we now have totally 150 employees, including 38 specialized technicians who have been working in this field for a medium or long term (including 5 senior engineers), 5 senior technicians, 4 technicians, 52 intermediate and senior technicians, and 4 professional after-sales service personnel, and are equipped with more than 100 sets of machining equipment, such as coordinate measuring machine (CMM) (imported from Norway), portable CMM, NC gantry-type milling machine, boring machine, rigid mill, milling tool machine, processing center, wire cut, NC flame cutting machine, abrator and various kinds of welding machines. We have fixed assets of more than RMB 20 million.

We have establish a close partnership with SCIVC Engineering Corporation and Zhengzhou Research Institute of Mechanical Engineering since establishment. We have also established closed relationship with many domestic automobile manufactures; therefore, we always master and lead the latest development tendency of China's automotive equipment.

In order to realize a better future, we, by upholding the spirit of exploration, learn widely from others' strong points and absorb foreign and domestic advanced experience, and strive for the development of China's automotive equipment!

[Corporate Philosophies]

Enterprise Spirit ---Dedication, Quality and Excellence

Business Philosophy --- Focusing on user and improving customer satisfaction

Enterprise Style --- Strict management, elaborate work, and pragmatic style

Working Principle --- Refining on each link and be meticulous at each test

We sincerely look forward to creating a better tomorrow with you!