Флюоресцентный газовый/Паровой Тип LiBr абсорбционный охладитель/нагреватель поглощающий чиллер прямого

- Категории: Industrial Chiller >>>

- Поставщик: Zhengzhou,Tongxing,Air,Conditioning,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Lithium Bromide Absorption Chiller

Lithium bromide absorption chiller is operating under high vacuum, which would be impaired by leaking of air into the chiller and noncondensable gases produced in the chiller due to corrosion. Poor vacuum will reduce chiller cooling capacity and even increase the corrosion of metal parts in a chiller. So high air-tightness is the decisive factor to guarantee the quality of lithium bromide absorption chiller,

and the key parameter for evaluation of chiller characteristics.

Main Features

1) Pioneering a chiller with two pumps and without spray nozzles solves the degradation of cooling capacity forever.

2) Solution heat exchanger with new construction and flow pattern improves chiller energy efficiency and reduces fuel consumption.

3) Distribution of refrigerant by dripping plates improves chiller energy efficiency and reduces fuel consumption.

4) New tubes and their arrangement in evaporator improves chiller energy efficiency and reduces fuel consumption.

5) Special construction of high pressure generator improves chiller reliability and energy efficiency, and reduces fuel consumption.

Packaging | ||

Size | 3780*2239*2152 mm | |

Weight | 6.7 T | |

Packaging Details | Export worthy for freight,marine,train transportation. unit: stretch film +foam + carton + pallet parts: plastic box+foam + box+carton | |

Quick Man-Machine Dialogue Interface

Data-setting

Control mode selection

Protection from mis-operation or ill intention

Operation record searching

Guidance to operation and maintenance

Shuangliang E-A Shell Structure

Solution heat exchanger with new construction and flow pattern improves chiller energy efficiency and reduces fuel consumption.

Heat exchangers are designed with new tubes and their supports, furthermore with new fl ow pattern, that leads to improve heat transfer and reduce fl ow pressure drop. These measures improved

chiller energy eff ciency and reduced fuel consumption.

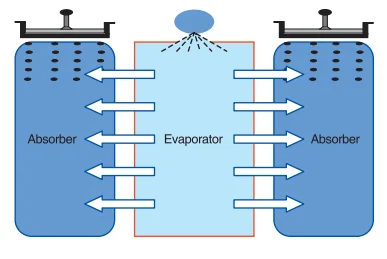

Shuangliang Two Pump Without Nozzle

Shuangliang constructed the f rst in China absorption chiller with two pumps and without spray nozzles, which eliminates the rapid degradation of cooling capacity. In order to attain the aim, a chiller with two pumps and without nozzles is manufactured with the knowhow,

such as Left-Middle-Right arrangement of absorber-evaporator-absorber, absorber with dripping plates instead of spray nozzles, which

did not needs solution spray pump. With this technology, the chiller can be operated for more than 20 years instead of 3~5 years.

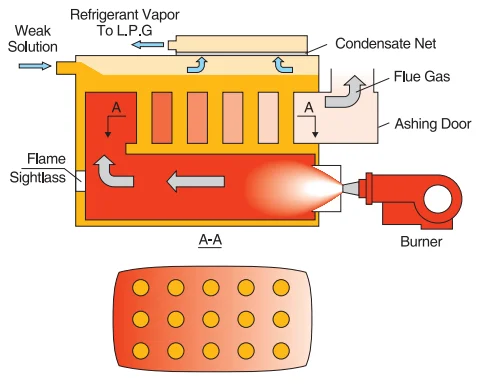

Flow Chart of H.P. Generator (Water Tube)

Serial flow of solution to improve chilller reliability.

Serial fl ow of solution in chiller makes solution fas fromcrystallization line to improve chilller reliability and simplify the control of chiller.