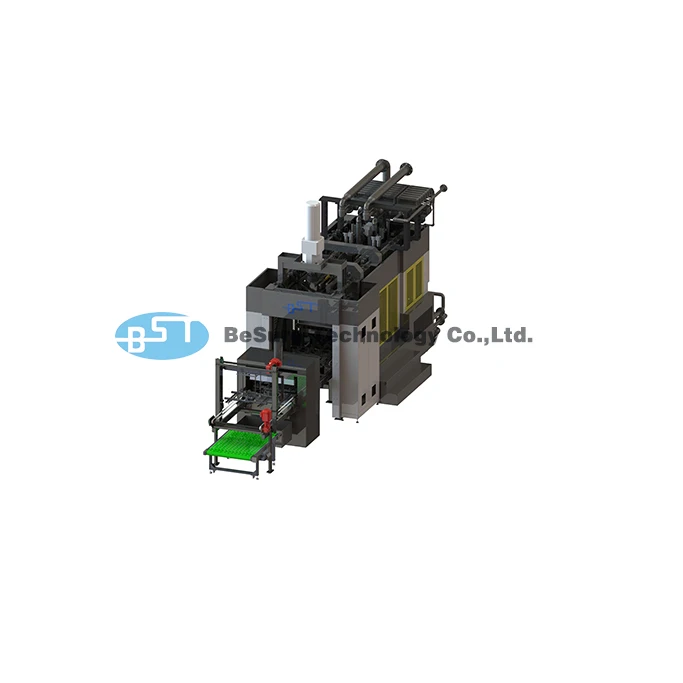

Полностью автоматическая машина для производства целлюлозы TW6000 контейнеров чаш и

- Категории: Paper Production Machinery >>>

- Поставщик: Foshan,Besure,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

BST Semi-automatic, full-automatic, automatic, pulp molding machine, pulp molding production line, pulp molded machine for table ware, catering ware, paper plate, pulp molded plate, paper bowl, pulp molded bowl, food containers, cup holders, saucers, food containers, high efficiency, energy-saving, with CE certified.

Product Parameters | ||

Product name | Disposable Paper Plate Machine | |

Model | TW6000 | |

Applicable industries | Food Processing Industry,Food Supply Industry,Catering Industry | |

Usage | Produce Disposable Molded Pulp Tableware,Molded Pulp Lunch Box, Meat Trays,Vegetable Trays,Paper Plate | |

Capacity | 6t/day | |

Production Consumption | ||||

Description | Consumption Per Hour | Remark | ||

Pulp | 255-285kg | |||

Water | 1.25-1.35t/hr | |||

Electricity | 1600-1800kw/hr | If heated by electricity | ||

Water-proof | 7.65-8.55kg/hr | Solid Content | ||

Oil-proof | 2.2-2.8kg | |||

Main Features

High precision servo motor drive,high efficiency and energy-saving drying line.

1,Use precision reducer servo motor forming and transferring to ensure smiith and fast operation.

2,Use absolute encoder to achieve accurate correction.

3,The use of bronze casting static and dynamic ring structure is more suitable for product dewatering process.

4,The use of mechanical structure to ensure that the mold close on both sides evenly.

5,Large capacity; Water content is low;Save the cost of drying.

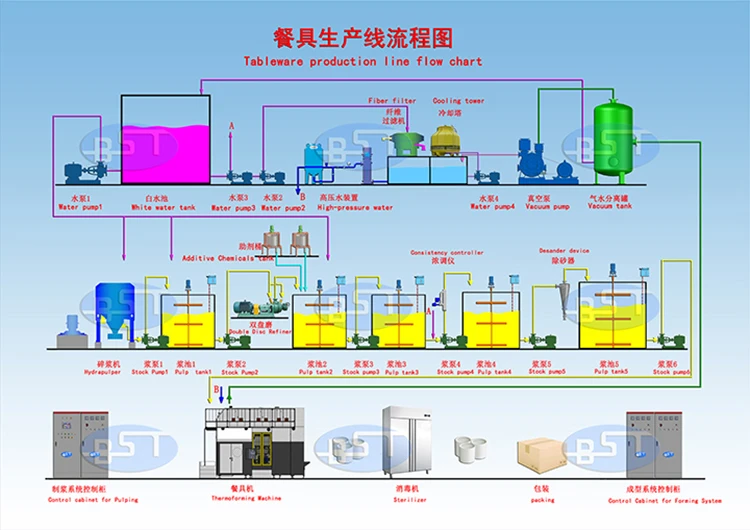

01 PULPING SYSTEM

Pulp board and clean waste paper will be made into pulp with certain concentration through pupling screening, grinding and addition of chemical agents, including:pupler,grinder,pulp tank, water tank,pulp pump,water pump,agitator,consistency and control cabinet.

02 FORMING AND HOT-PRESSING SYSTEM (with the function of forming,drying,hot pressing and stacking)

The pulp is vacuumized to evenly attach to special forming mold as wet blank which is transferred to hot pressing mold ,with finished products made through drying and hot pressing processes;finally products will be transferred and stacked together.

03 VACUUM SYSTEM

Supply vacuum for product forming.

04 AIR COMPRESSOR SYSTEM

Supply compressed air for forming machine.

05 HIGH PTESSURE WATER SYSTEM

Supply high pressure water for washing molds of forming machine.

06 POST TREATMEBT(cementing Machine)

Some products shall be subject to post treatment,e.g.:edgecutting ,punching ,coating ,labeling and printing.BST can provide the corresponding machines.

07 POST TREATMEBT(Laminating Machine)

Some products shall be subject to post treatment,e.g.:edgecutting ,punching ,coating ,labeling and printing.BST can provide the corresponding machines.

08 POST TREATMEBT(Trimming Machine)

Some products shall be subject to post treatment,e.g.:edgecutting ,punching ,coating ,labeling and printing.BST can provide the corresponding machines.

Production Line Overview

Automation Condition;Fully automatic production line.

Output: 6T/Day.(10 "dish,weight:20±2g)

Operator Required: 6-7people/shift to operate the whole system.

Recommended Workshop Size: 24x 48 (m), height>6m.can be adjusted according to customer's requirement

Installation: Supplier should appoint 2 engineers to instruct buyer in installstion,test-run and training

Warranty: Life-long service, sustainable supply and upgrade of parts and components,One-year warranty( three-year warranty for machanical parts and main structure)

Production line configuration: The production line is standard,can also be customized according to customer demand,can be used to produce a variety of pulp molding tableware,such as meal boxes,dishes,plate,discs,separators,etc.

Pre-sales service

With more than 20 years of accumulated technical experience, we will be based on your investment intentions, such as capital, plant, target market and other details of a full range of analysis.

On sale service

1.According to your internal size of the workshop, we will not only provide you detailed layout, the planning of pipe and line design, also provide basis of your equipment infrastructure construction, procurement and installation of materials.

2.When equipment into the factory, by the capable installation team to install and debug; After commissioning, the staff training of the system, including two parts: classroom explanation and practice, the structure of the equipment, principle and production technology, day-to-day maintenance and common troubleshooting and other contents of the detailed explanation and practical exercises.

After-sale service

The equipment we sold: "Lifelong tracking service, one year free warranty" (except for vulnerable parts and abnormal failure), one year after, the cost of spare parts and service.

Paper Plate Machine

Capacity:2000T/Day

Paper Plate Machine

Capacity:4000T/Day

Paper Plate Machine

Capacity:6000T/Day