Сушильная камера с зеленой основой или сухая для

- Категории: >>>

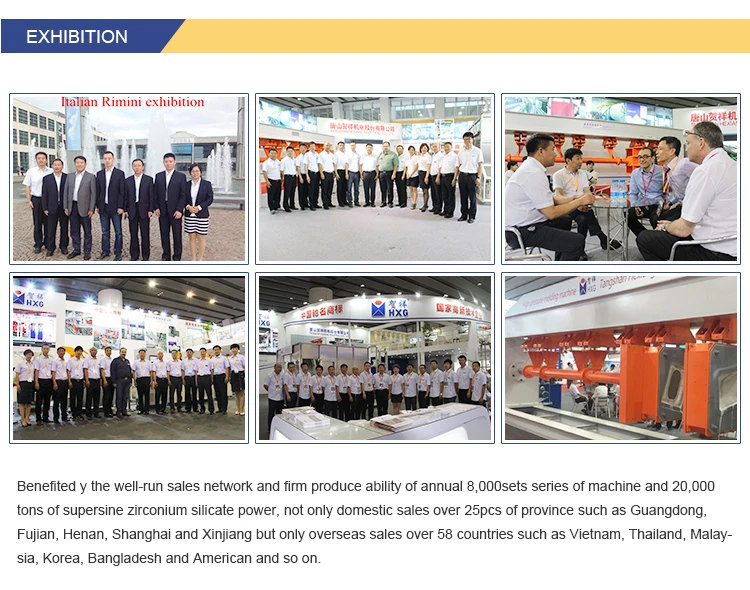

- Поставщик: Tangshan,Hexiang,Intelligent,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Ceramic dryer machine with drying chamber

This equipment mainly used in ceramic industry fast drying green body and plaster mould, this machine adopts advanced automatic control and user-friendly man-machine interface to achieve a fully automatic constant temperature and humidity, automatic row tide, which greatly improves the drying efficiency, reduce work-area.

Technical data:

1-- Automatic control of temperature and humidity

2---PLC control method, with SIEMENS or OMORN, automatic stabilization,

3---Humidity control by Vaisala from Finland

4--Power of 27.9KW= (4×4+7.5×1+1.1×4)

5--calculated as 50% of daily capacity to be dried

6--Material of wall is insulating rockwool with thickness of 75mm

7--4 pcs of wind-tube which realize a better even air distrubtion

8--Drying cycle is 8~18 hours

9--Burner of Riello, model of RS50, with max output power of 500000Kcal/h

Upgrade type for dryer chamber, dryer room

1--Main frame: square pipe, Q235 tube

2--Wall and roof material: polyurethane plate, thickness: 75mm, volume weight: 40kg/m3, fireproofing, antiflaming.

3--Hot air pipe: galvanized pipe: δ75

4—with axial fan, electric air shutter with open and close function with feedback.

5—air outlet: Beijing broll

6—electrical control: Simens brand

7—temperature sensor

8-- Burner of Comtherm, Britain brand

Dryer chamber Main technical data | ||

Dryer room area | 20-250m2 | |

Door size: W x H | 2x2.4m | |

Door type: | hinged door for heat preservation or lifting door | |

Temperature in room | Max 85 degree | |

Dryer time | 14-18 hours | |

Burner brand | Riello from Italy | |

Fuel | Natural gas | |

Calorific value | 8600kcal/Nm3 | |

Maximum output power | 440000Kcal/h | |

Model and specification of heat resistant main fan | type: TCX710-I | power: 4Kw |

Blast capacity | 18000m3/h | |

Full pressure: | 580Pa | |

Circulating fan model and specification: | type: TCX710 | power: 5.5Kw |

Air volume: | 28000m3/h | |

Full pressure: | 340Pa | |

Water contents after dryer: | 1% | |

ceramic making machine, hi-pressure casting machine for toilet(water closet),sanitary ware making machine