- Главная

- Все Категории

- Магнитные материалы

- Канцелярские кнопки пластиковый магнит Pawn

Канцелярские кнопки пластиковый магнит Pawn

- Категории: Магнитные материалы >>>

- Поставщик: Shenzhen,Aim,Magnet,Co.,Ltd.,[Guangdong,China]Shenzhen

Поделиться:

Описание и отзывы

Характеристики

| Material | Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Size | Various kinds or according to customers' request | |

| Shape | Customized (block,disc,Cylinder, Bar, Ring,Countersunk, Segment, hook, cup, Trapezoid, Irregular shapes ,etc) | |

| Performance | Customised (N33 N35 N38 N40 N42 N45 N48 N50 N52 ......) | |

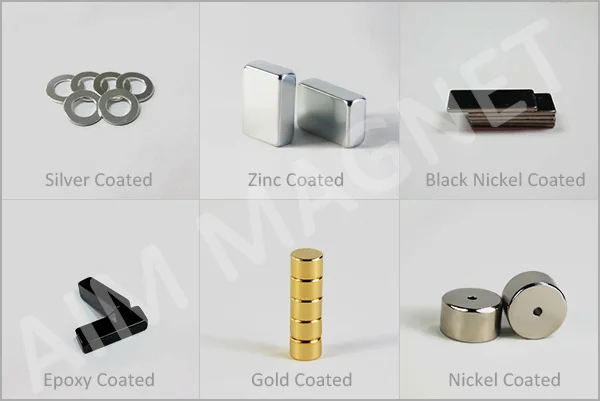

| Coating | Customised (Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, etc) | |

| Size tolerance | ±0.05mm for diamater /thickness, ±0.1mm for width/ length | |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Customzied specific requirements magnetized) | |

| Max. Working Temperature | Grade | Max. Operating Temperatures |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors, microphones, wind turbines, wind generators, printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. | |

| Shape | Block/Rectangle/Square | Disc/Round/Cylinder | Ring/Countersunk |

| Dimension | L (?) x W(? ) xT(?) | D(?) x T(?) | OD(?) x ID(?) x T(?) |

| For other shapes,please tell more in details or drawing would be much appreciated. | |||

| Coating | Zn, Nickel, Ni-Cu-Ni, Epoxy, Au, Silver or other? | ||

| Working Temperature | Normal or High temperature? | ||

Magnet is special goods for shipment , they need to make special packing when shippment is ship by air.AIM magnet company Limited have more than 12 years export experience and transportaion experience.We will arrange air shipment in good condtion.

1.Why are chosen us?

- We are a professional magnet manufacturer since 2006. Our plating factory is the benchmark in the Shenzhen NdFeB industry.

- No returned goods for five years in Europe market.

- We provide magnets for a dozen of Fortune Global 500 enterprises such as Apple, Samsung, Lenovo etc.

- In Europe market, 80% permanent magnets used for range hood are from AIM Magnet Co., Ltd.

- Our company is the main supplier of American top wine box.

- With rich exporting experiences with neodymium magnets, we build supply chain to offer neodymium magnets with professional service.

2. How to control the magnetic property?

- Hight stander raw material

3. How to control the tolerance?

- 1. before ginding and cuting, we inspection the black product tolerance.

- 2. before and after coating, we will inspection the tolerance by AQL standard

- 3. before delivery, will inspection the tolerance by AQL standard

4. How to guarantee the consistancy?

- 1. the sintering control will make sure the perfect consistancy.

- 2. we cut magnet by multi-wire sawing machine to guarantee the dimension consistancy.

5. How to control coating ?

- 1. we have a coatIng factory

- 2. after coating, first inspection by visual, and second is salt spray test, nickel 48-72 hours, zinc 24-48 hours

6. How to control the packing?

- 1. standard packing,

- 2. the cartons must can be bear a man's weight.

- 3. the cartons must be well after fall down test from 1m high position. and the inner packing must not change position