Заводская цена алюминиевый выплавильный горшок 25

- Категории: Промышленные печи >>>

- Поставщик: Yongkang,Yuelon,Electronic,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

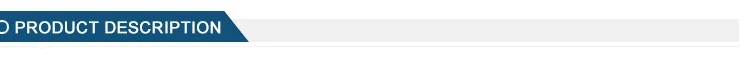

Характеристики

Product name | High frequency induction heating machine with separate transformer | ||

Models | MF-25 | Input voltage | 380V±10% 3-phase, 50/60Hz |

Maximum input power | 25KW | Power supply cooling water desire | ≥0.2 Mpa ≥3L/Min |

Output frequency | 1-20KHz | Whole system cooling water desire | ≥0.2 Mpa ≥6L/Min |

Max input current | 36A | Duty cycle | 100% |

Auto heating time | 1-99S | Generator N.W. | 28 kg |

Auto retaining time | 1-99S | Generator size (L x W x H) | 460 x 270 x 450mm |

Auto cooling time | 1-99S | Packing weight | 50KG |

Features of induction heating equipment:

1. High efficient: energy saving, environmental protection.

2. Heating fast: the fastest heating speed is less than 1 second.

3. Heating wide: can heating variety of metal workpieces (according to different shapes of work pieces, replace removable induction coils).

4. Easy installation: the machine can be used as soon as connected the power supply, induction coils, water inlet and outlet.

5. Small size, light weight, easy to use.

6. Simple operation, several minutes to learn.

7. Start fast, pass water and electric power can start heating.

8. Low power consumption: Energy saving 15%-20%, compared to SCR/KGPS technology Much more efficient than gas-fired and coal-fired method.

9. Good effect: Heating very uniform (by adjusting the induction coils, makes every parts of work piece obtain the respective needs of temperature), warming up fast, less oxidation layer, surface got good gloss after heating.

10. Full protection: has over voltage,over current,temperature is over high,lack of water, lack of phase,etc, alarm lamps indicators. can automatically control and protection the machine itself.

11. Temperature is adjustable, by setting heating time and the infrared thermometer, to control heating temperature of work pieces. thus control heating temperature to a technology points.

12. High security, eliminating the nearly million-Volt high voltage.

Note:

1. The output voltage of medium frequency induction heating generator is 70-550V, high voltage exist on the output connector of the generator and the connector of the compensating capacitor, and especially exists on the induction coil and the connecting cable between generator, capacitor and induction heating coil, so it is very important to insulate all these high voltage connector and parts for the safety of the operator.

2. Whenever poor insulation of the induction heating coil and connecting cables is found, the working must be stopped until good insulation is reformed.

3. For the safety of the operator, it is suggested that the insulating clothes, gloves and boots be worn.

4. The operating table must be made using insulating material.

5. Any change of the connecting the machine, can only be done when the power is off for the safety of the operator.

6. Repair and maintenance of the induction machine can only be done by trained personal.

7. When the induction heating machine is working, do not touch the induction coil and any components inside the machine.

8. High efficiency can only be achieved when there is proper adaptation between generator and capacitor and the induction coil, so please consult with our experts whenever you need.

9. Fast connectors is used to connect from generator to the capacitor, and good connecting is very important for the use of the induction heating machine. The plug must be locked very well to ensure good electrical connection, failure is easily caused by un-proper connection or loose of the plug.

10. Because of the high input power of the machine, good connecting of the input wire should be ensured.

11. Ground with 6mm soft copper wire for the safety of the operator.

12. Cooling water is very important, clean and soft water can reduce the destroy of the induction heating machine,and temperature of the cooling water would not exceed 40°C , So before installation, read carefully the appendix for water system installation.

13. It is suggested that cooling water be lasted another half a hour when finishing everyday work.

Q:Why can I trust your company and choose you?

A: We are a professional induction heating equipment and set r & d, production, sales, service as one of the high-tech enterprises.We have 22 years of professional experience in production and equipment research and development, is currently China's most professional brazing machine, heating complete automation equipment manufacturers.

Q:Where is your company, may I come to visit?

A:Yes,our company located in NO.25 Jinshan East Road,Wujin Technology Park,Yongknag,Jinhua,Zhejiang,China. And you will be welcome to visit our factory at any time

Q:How to install your machine?

A:We have paper installation instructions and video, we will teach till you learn it.

Q:Do you have any equipment in stock?

A:Yes, we have some of the best-selling models in stock, and can shipped immediately after payment

Q: Can you provide free samples of the machines?

A: Sorry, but we can't give you free samples because of the high price of the machines. Our machines will certainly meet your requirements and satisfy you

Q:How is your quality control?

A:We have a professional team responsible for product testing and packaging before delivery, you can be assured to purchase.

Q:How many days can the machine arrive after I bought it?

A:Usually 5-10 days(excluding holiday),large machines take 20-30 days

Q: If the machine get damaged, what can I do ?

A: We will give you some spare parts free of charge during the one-year shelf life of the machine.For the customers who have bought the machine, if there is any problem with the machine, they can take a photo or record a video to us. We will guide the customers to perform the repair.If we still cannot solve the problem, we can send our engineers to your factory.

Q.How about the warranty?

A: All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.