Индивидуальная зеркальная алюминиевая лампа с высоким отражателем для

- Категории: Lamp Covers & Shades >>>

- Поставщик: Shenzhen,Dixuan,Metal,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

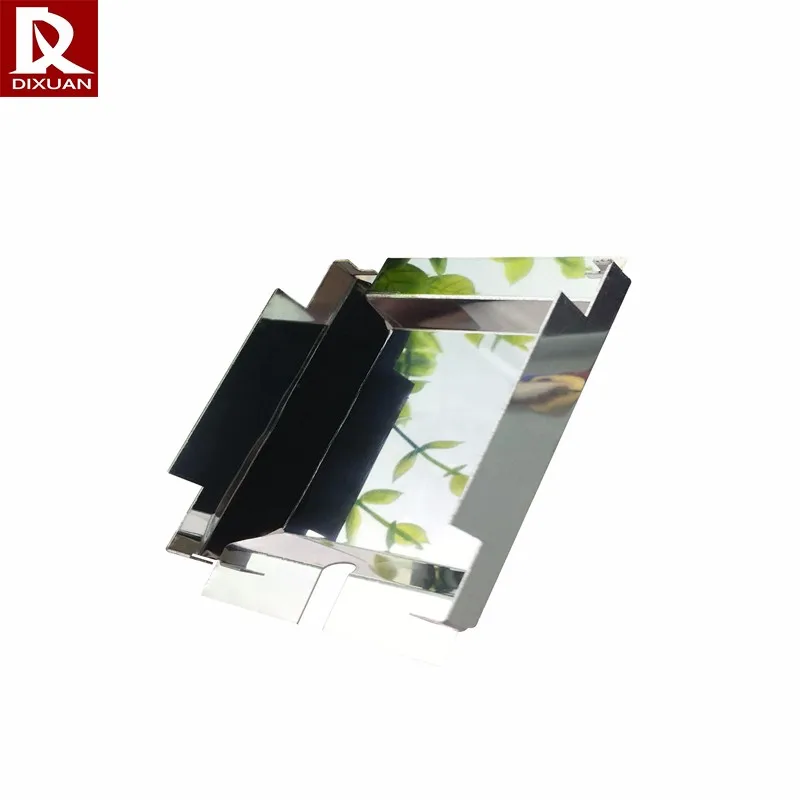

Grille Light Aluminium Reflector cover

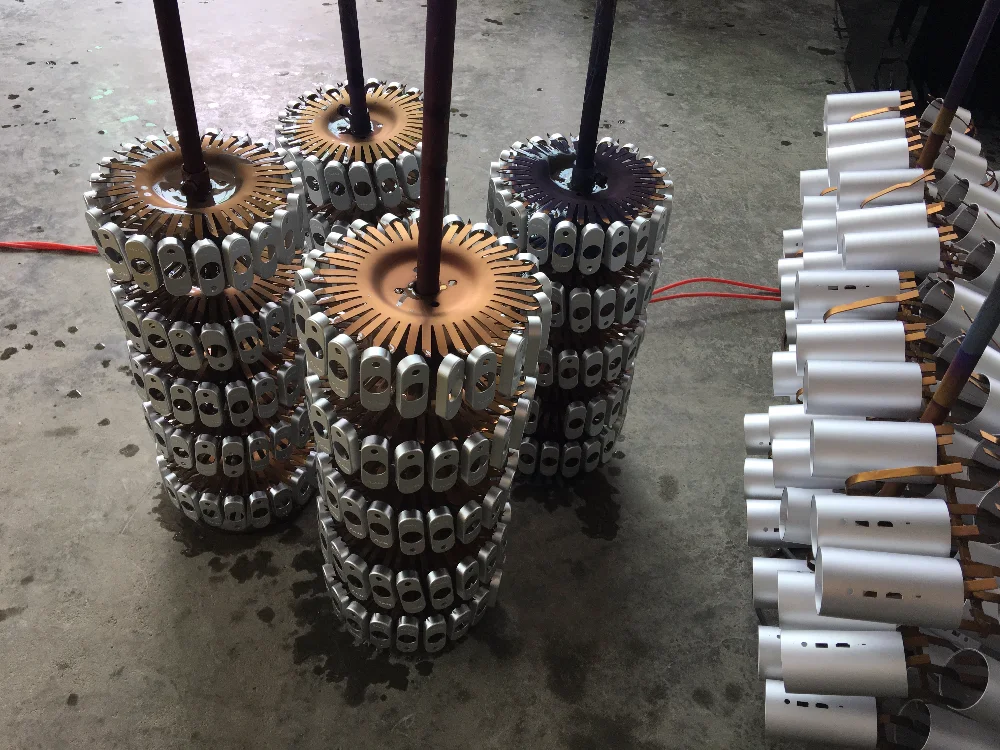

This special product are used for grille light reflector. Some customer buy the whole light, some buy this reflector cover and they assemble on site by themselves.

Name | Reflector Mirror Aluminum Lamps Shade |

Material | Aluminum sheet |

Color | silver |

Payment | T/T, D/P, D/A, L/C, etc. |

Reflectivity | 86%, 95%, 98% |

Surface treating | reflector mirror |

Application: | grille lamp Reflector cover |

Advantage | With competitive price and quality assurance |

Note:

Most of the metal parts are customized design, not available in stock, so if you need

any part, please send us your technical drawing or sample for quotation.

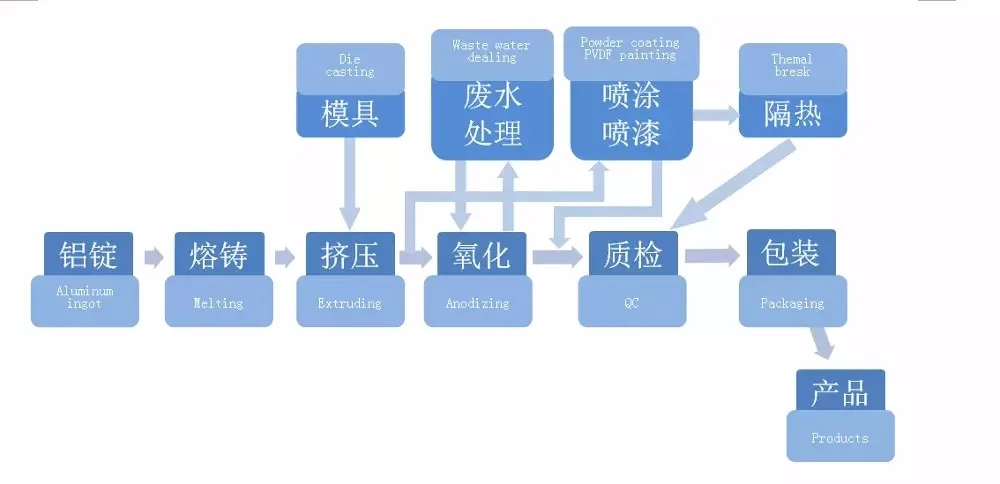

Shenzhen Dixuan Metal Co., Ltd.

Our company mainly produces and sells mirror

aluminum plate, oxide aluminum plate, color mirror

aluminum plate and various aluminum plate customized products,

so as to "individualize, create" better service customers.

1. Why do many people choose aluminum oxide plate anodized aluminum plate?

(1)\tGood processability: Anodized aluminum sheet has strong decoration, moderate hardness, easy bending and forming, continuous high-speed stamping, convenient for direct processing into products, no more complex surface treatment, greatly reducing the production cycle and product cost.

(2)\tGood Weatherability: Standard thickness of oxide film (3 micron) anodized aluminum sheet use indoors for long periods without discoloration, no corrosion, no oxidation, no rust. An anodized aluminum sheet with a thickened oxide film (10 microns) can be used outdoors and be exposed to the sun for a long time without discoloring.

(3)\tStrong sense of metal: high surface hardness of aluminum plate treated by anode, up to gem grade, good scratch resistance, the surface is not covered with paint, retain the metal color of aluminum plate, highlighting modern metal sense, improving product grade and added value.

(4) High fire resistance: pure metal products, no paint and any chemical substances on the surface, 600 degrees high temperature does not burn, do not produce toxic gases, meet fire protection and environmental protection requirements.

Strong stain resistance: No fingerprints, no stain, easy to clean, no corrosion spots

Strong applicability: Widely used, suitable for metal aluminum ceiling, curtain wall board, aluminum plastic panel, fire prevention board, honeycomb aluminum board, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

2. Application range of Anodized aluminum sheet for alumina plate

Anodized aluminum sheet is widely used in mechanical Parts, Aircraft car Parts, Precision instruments and radio equipment, Architectural Decoration, machine casing, Lamp Lighting, consumer electronics, Crafts, Household appliances, Interior Decoration, signs, Furniture, automobile decoration and other industries.

Packing

Individual poly bag for each

Delivery Time

25 working days after 30% T/T payment received.

PS.

If there is any product you want, please contact me, thank you.

Q1: How can you guarantee the quality of mass goods is same as the sample sent to me before?

A2: We kept another same sample and marked on company when we sent to customer. So our production will be based on.

Q2: What about the package of product?

A2: According to customer requirements.

Q3: What's the payment?

A3: 30% T/T in advance, 70% after send the copy of the BL. Or L/C, Western Union ,USD.

Q4: If I need sample, what should I do?

A4: It's our pleasure to send sample for you. You can send me your delivery address by email or message.We will send you free sample at first time.