Машина для производства древесного угля кукурузного стебля рисовой шелухи опилок

- Категории: Energy Saving Equipment >>>

- Поставщик: Zhengzhou,Meida,Machine,Co.,LtdZhengzhou,Ltd

Поделиться:

Описание и отзывы

Характеристики

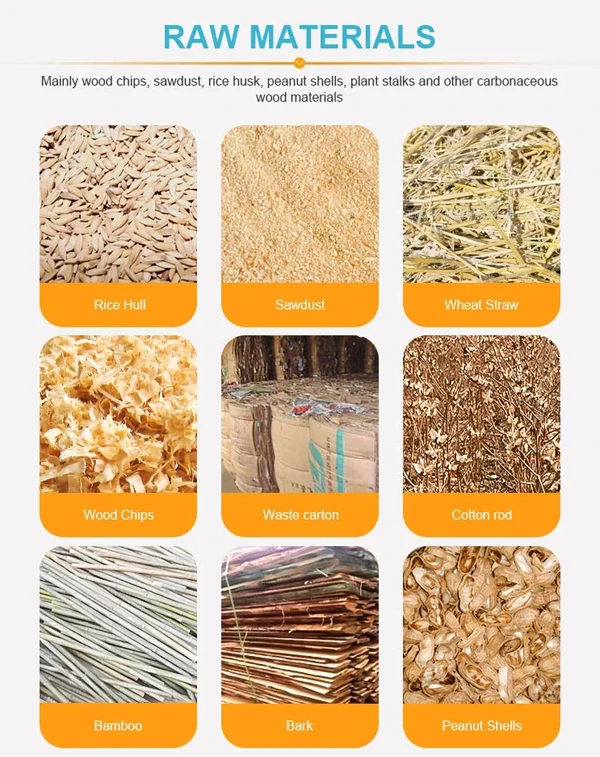

About the raw materials : any biomass materials is ok

Wood log/ coconut shell / palm / peanut shell / rice husk/ straw ...... more than 30style

1 Biomass briquette extruder

1.raw materials moisture: 8-12%

2.biomass briquette density : 900-1400kg/m

3.final briquette length : machine with a automatic cutter, any length can be made

4.final briquette shape : hexagon or square shape

5.final briquette size : diameter 50mm & inside hole 15mm

6. spare parts include mould, heating ring, oil seal, propeller, welding rod, temperature controlled meter

Different Models of Biomass charcoal briquette extruder machine

Model | Power | Weight | Capacity | Size |

250 | 18.5kw | 1100kg | 250-300kg/h | 1.6*0.55*1.25m |

450 | 22kw | 1400kg | 350-450kg/h | 1.7*0.55*1.55m |

Coal stick briquette extruder

Basic Introduction of coal stick briquette press machine

Work Principle: change charcoal powder or coal or other powder into briquette

Final products shape : mold style : square, round, hexagonal, plum blossom and so on

Main Features of the machine

1. This machine can make coal and charcoal powder into sticks.

2. The shape of the sticks can be made by customers’ requirements.

3. The final product made by this machine is no pollution or smoke.

4. It is suitable for charcoal powder, wood charcoal powder, coconut shell charcoal powder, rice husk

charcoal powder, charcoal dust, coal powder.

5. Material required size: <3mm

6. The shape and size of stick can be made as required, such as round, hexagon, cinquefoil, and other

shapes, in the stick center, it can be made with a hole or not.

7. For the length, the automatic cutter is available.

charcoal briquette making machine

Different models of coal briquette make machine

Model Style | 140 | 180 | 300 | 450 |

Capacity | 1-2t/h | 2-3t/h | 3-5t/h | 8-12t/h |

Power | 11kw | 22kw | 90kw | 220kw |

Diameter of briquette | 18-80mm ( buyer need tell us what diameter you need ) | |||

Speed | 60rpm | 60rpm | 132rpm | 132rpm |

Spiral impeller diameter | 120mm | 160mm | 270mm | 420mm |

Size | 1.9*1.1*1.17m | 2.2*1.37*1.44m | 3.6*1.4*1.45m | 5.13*1.52*1.5m |

Raw materials size | <3mm | |||

Raw materials moisture | 12-14% | |||

Charcoal ball press machine

he briquette briquetting machine is a ball-making equipment, which can continuously send various powder materials to the roller pressing area through the pre-pressing device, and press the powder into balls under the pressure of the roller pressing area

| Model | 290 | 360 | 360B |

| Capacity | 2-3t/h | 3-4t/h | 5-6t/h |

| Roller width | 200mm | 250mm | 250mm |

| Roller diameter | 290mm | 360mm | 360mm |

| Power | 5-7.5kw | 7.5-11kw | 7.5-11kw |

| Rotary speed | 18r/min | 18r/min | 18r/min |

| Roller material | Wear-resistant alloy | Wear-resistant alloy | Wear-resistant alloy |

2 carbonization furnace

How to make biomass briquette charcoal ?

A: crush raw materials into size less than 1cm

B: raw materials moisture more than 12% , need use dryer ( less than 12% no need)

C: briquette extruder machine press it to get briquette ,which with density 900-1400kg/m

D: carbonize furnace change briquette into charcoal briquette

3 How to get charcoal from wood log directly ? only use charcoal carbonization furnace

A: one machine include : 3 inner pot + 1 outer stove + 1 hoist

B: one machine each day make charcoal 2-3tons , this is final charcoal capacity

C: raw materials moisture different, the final capacity also will different

( because more moisture means carbonize time will longer )

D: for more video & photo & MANUAL, Contact us by email or whatsapp please.

Different Models of charcoal carbonization stove/furnace/kiln

4 continuous charcoal production line

Full technical details of all models

Model | WTJ-3 | WTJ-4 | WTJ-5 | WTJ-6 |

Carbonize body diameter | 800mm | 1000mm | 1200mm | 1500mm |

Capacity | 400-600kg/hour | 800-1000kg/hour | 1200-1500kg/hour | 2000-3000kg/ hour |

biomass gas furnace diameter | 1700mm | 1700mm | 1700mm | 1700mm |

biomass gas furnace motor | 1.1kw+3kw | 1.1kw+3kw | 1.1kw+3kw | 1.1kw+3kw |

Fan motor(Frequency) | 5.5kw | 5.5kw | 5.5kw | 5.5kw |

Continuous charcoal powder produce parts | 3kw | 3kw | 4kw | 5.5kw |

Cooling parts | 3kw | 3kw | 3kw | 4kw |

Spiral feeding | 3kw | 3kw | 3kw | 3kw |

Condenser | 2pcs | 2pcs | 2pcs | 2pcs |

Spiral separator | 2pcs | 2pcs | 2pcs | 2pcs |

Oil liquid separator | 2pcs | 2pcs | 2pcs | 2pcs |

Burner | 16pcs | 16pcs | 18pcs | 20pcs |

Smaller burner | 2pcs | 2pcs | 2pcs | 2pcs |

Carbonize work temperature | 500-800℃ | 500-800℃ | 500-800℃ | 500-800℃ |

Q1:How Many raw materials can get 1 ton final charcoal ?

A1:usually 2.5-3tons raw materials to make 1ton final charcoal

Q2: What is the normal temperature for carbonizing?

A2: The temperature should around 400°C

Q3: Whether you can sent engineer to do machine install ?

A3: Yes,we can sent engineer to do install & worker training