99.9995% поставщик оборудования для очистки азота и генератора

- Категории: >>>

- Поставщик: Hangzhou,Boxiang,Gas,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

99.9995% Nitrogen Purification Hydrogen generator Equipment supplier

Purification process is combined with two kinds of high efficient catalysts, Hydrodeoxygenation at normal temperature,Removing excess hydrogen(When there is a requirement for hydrogen),The high purity nitrogen were obtained through purification process Removal of water and impurity.

1.Technical characteristics

+ Automatic control of hydrogenation and high automation, Safe and reliable.

+ Using high efficient catalysts, Advanced technology and stable performance.

+ Using safe and reliable control elements , operate reliably.

+ Intelligent interlocking and emptying, a variety of fault alarm, Users find and solve problems in time.

+ Dehydrogenation at normal temperature,no activation,wide range of deoxgenation.

2.Technical Index

| 1 | capacity: | 10-20000Nm3/min |

| 2 | Nitrogen purity: | ≥99.9995%. |

| Nitrogen Pressure: | 0.1-0.7MPa(adjustable) | |

| 3 | Oxygen content: | ≤5ppm |

| 4 | Dust content: | ≤0.01um |

| 5 | Dew point: | ≤-60℃. |

3.Technical parameters

Products Show

Features

1. the press swing adsorption theory is very stable and reliable.

2. purity and flow rate can be adjusted in a certain range.

3. resonable inner structure, keep the balance airflow, alleviate the air high speed impact

4. unique molecular sieve protective measure, extend the working life of the carbon molecular sieve

5. easy installation

6. process automation and easy operation.

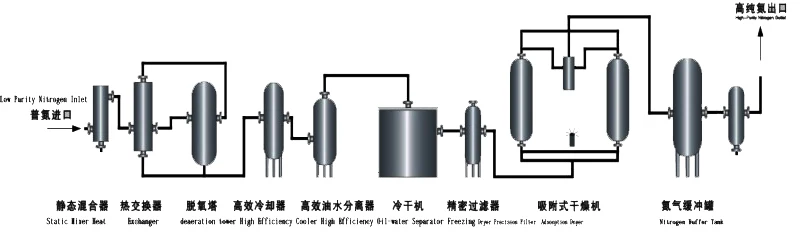

After the mixture of nitrogen and hydrogen is fully carried out in the static mixer, the heat is utilized and the reaction efficiency is improved by entering the heat exchanger. The high-heat nitrogen, oxygen and hydrogen gas enters the deoxidizer to catalyze deoxidization. After the gas comes out, it is nitrogen with trace oxygen, high temperature and water content. Then it is imported into the cooler to reduce its temperature to normal temperature, and then it is imported into the adsorption dryer, which can effectively remove the heat. Carbon dioxide and water can reduce the effective gas consumption, (gas consumption is 5%) and finally filtered by dust filter, the purity is 99.9995%.

| (1) | --Food packaging (cheese, salami, coffee, dried fruit, herbs, fresh pasta, ready meals, sandwiches,etc. ..) |

| (2) | --Bottling wine, oil, water, vinegar |

| (3) | --Fruit and vegetable storage and packing material |

| (4) | --Industry, tire, fire extinguisher, mineral industry, electronic industry and so on |

| (5) | --Medical |

| (6) | --Chemistry |

| (7) | --Lab |

RELATED PRODUCTS SHOW

Q1: Are you mancfacturer or trader?

A: We are professtioanl manufacutrer in air separation plant area.

Q2: What's your main products?

A: Our main pruducts are PSA nitrogen generator, VPSA oxygen genertor, PSA oxygen generator, small-sized liquid nitrogen genertor, compressed air and compressed air filters.

Q3 What is the delivery time of your gas generator?

A: Generally 45 days.

Q4: What is your payment terms?

A: TT and L/C are acceptable.

Q5: What's your advantages?

A: We supply excellent quality, vavorable price, good pre-sale service and after-service.

Q6: Where is your port of shipment?

A: FOB Ningbo or Shanghai.

Q7: How to get a prompt quotation?

A: Please tell us the usage, productivity, purity, pressure and your other requirements about the plant.

Q8: Your products are exported to which countries?

A: Our products are exported to Russia, Germany, The United States,Indonesia,Myanmar,Pakistan,Kazakhstan,Uzbekistan,Bangladsh,Malaysia,Brazil and other Countries.

Send Inquiry Please bring the following description, we have more models to recommend to you ~!

Thank you~! Best Regards

| Technical Information | Your Kind Requirement |

| Capacity | _________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Dew Point | _________℃ |

| Power | ________V/HZ |