plastic raw material/Fast cycling Grade/polystyrene resin/C-103

| Product Specifications : |

| A SERIES Standard Grade |

| Code |

Beads size |

Foam mulfiple |

Foam density(G/L) |

APPLICATION |

| A-103 |

1.00-1.60 |

70-90 |

11-14 |

USE FOR BLOCK AND LOW DENSITY PRODUCT |

| A-104 |

0.85-1.25 |

65-85 |

12-15 |

USE FOR PRODUCT MORE THAN 12MM THICK |

| A-105 |

0.70-1.00 |

60-75 |

13-17 |

USE FOR MIDDLE DENSITY PACKING PRODUCT,FRUIT BOX,FISH BOX,VEGETABLE BOX |

| A-106 |

0.50-0.80 |

55-70 |

14-18 |

USE FOR PRODUCT MORE THAN 8MM THICK |

| A-107 |

0.40-0.50 |

30-65 |

15-18 |

USE FOR PRODUCT MORE THAN 6MM THICK |

| |

|

|

|

|

| B SERIES High Expansion Grade |

| Code |

Beads size |

Foam mulfiple |

Foam density(G/L) |

APPLICATION |

| B-103 |

1.00-1.60 |

80-100/180-200 |

10-12.5 |

USE FOR ELECTRIC PACKING BLOCK |

| B-104 |

0.85-1.25 |

70-90/160-180 |

11-14 |

CRAFTWORK, BOX ETC,ESPECIALLY USE FOR |

| B-105 |

0.70-0.10 |

60-80/130-150 |

12.5-13 |

LOW DENSITY BLOCK |

| B-106 |

0.50-0.80 |

50-60/60-90 |

13-18 |

|

| B-107 |

0.40-0.60 |

30-40/40-70 |

25-33 |

|

| |

|

|

|

|

| C CERIES Flame retardant Grade |

| Code |

Beads size |

Foam mulfiple |

Foam density(G/L) |

APPLICATION |

| C-103 |

1.00-1.60 |

45-65 |

6-14 |

USE FOR BLOCK AND BIG PACKING PRODUCT |

| C-104 |

0.85-1.25 |

40-65 |

8-16 |

USE FOR BLOCK AND BIG PACKING PRODUCT |

| C-105 |

0.70-1.00 |

40-60 |

12-18 |

USE FOR BLOCK AND MIDDLE DENDITY PACKING PRODUCT |

| C-106 |

0.50-0.80 |

30-50 |

15-18 |

USE FOR HIGH DENSITY BLOCK AND SPECIAL USE PRODUCT

|

| C-107 |

0.40-0.60 |

25-40 |

15-20 |

USE FOR HIGH DENSITY BLOCK AND SPECIAL USE PRODUCT

|

| |

|

|

|

|

| D SERIES Fast Cycling Grade |

| Code |

Beads size |

Foam mulfiple |

Foam density(G/L) |

APPLICATION |

| D-103 |

1.00-1.60 |

60-70 |

14-17 |

USE FOR ELECTRIC PACKING, BLOCK

AND CHINA PACKING AND HIGH DENSITY PROUDUCT

|

| C-104 |

0.85-1.25 |

50-65 |

15-20 |

| D-105 |

0.70-01.0 |

40-60 |

17-25 |

| D-106 |

0.50-0.80 |

35-55 |

18-30 |

| |

|

|

|

|

| Properties: |

C Flame retardant Grade

| Specification |

C-103 |

C-104 |

C-105 |

C-106 |

| Beads Size mm |

1.00-1.60 |

0.85-1.25 |

0.70-1.00 |

0.50-0.80 |

| Vol.Cont % |

6.85 |

6.8 |

6.66 |

6.27 |

| H2O % |

0.95 |

1.12 |

1.25 |

1.26 |

| F.M % |

≤0.10 |

≤0.10 |

≤0.10 |

≤0.10 |

| Avg.size mm |

1.32 |

1.01 |

0.8 |

0.63 |

| PRE-EXPENSION DENSITY |

15.0-22.0 |

15.0-25.0 |

17.0-25.0 |

20.0-33.0 |

| Sieving ≥ 95% |

95.0 |

95.0 |

95.0 |

95.0 |

| Oxygen Index |

≥30 |

≥30 |

≥30 |

≥30 |

| Remark |

ALL THE DATA IS BASED ON LAB TEST FOR FIRST TIME EXPANSION IN CONTINOUS EXPANDER |

Flame retardant grade is the one of the most competitive products in our company. Export to many countries.There are quite a number of regular customers of this grade. Every month about 1500 tons for export.

|

| |

B High Expansion Grade

| Specification |

B-103 |

B-104 |

B-105 |

B-106 |

B-107 |

| Beads Size mm |

1.00-1.60 |

0.85-1.25 |

0.70-1.00 |

0.50-0.80 |

0.40-0.60 |

| Vol.Cont % |

7.80 |

7.66 |

7.53 |

7.39 |

7.21 |

| H2O % |

0.50 |

0.57 |

0.61 |

0.59 |

0.37 |

| Avg.size mm |

1.36 |

1.02 |

0.83 |

0.63 |

0.50 |

| Sieving ≥ 95% |

95.00 |

95.00 |

95.00 |

95.00 |

95.00 |

| Remark |

ALL THE DATA IS BASED ON LAB TEST FOR FIRST TIME EXPANSION IN CONTINOUS EXPANDER |

|

|

A Standard Grade

| Specification |

A-103 |

A-104 |

A-105 |

A-106 |

A-107 |

| Beads Size mm |

1.00-1.60 |

0.85-1.25 |

0.70-1.00 |

0.50-0.80 |

0.40-0.60 |

| Vol.Cont % |

6.80 |

6.77 |

6.59 |

6.32 |

6.10 |

| H2O % |

0.39 |

0.43 |

0.40 |

0.45 |

0.40 |

| F.M % |

≤0.30 |

≤0.30 |

≤0.30 |

≤0.30 |

≤0.30 |

| Avg.size mm |

1.35 |

1.02 |

0.81 |

0.63 |

0.50 |

| PRE-EXPENSION DENSITY |

11.0-14.0 |

12.0-15.0 |

13.0-17.0 |

14.0-18.0 |

15.0-18.0 |

| Sieving ≥ 95% |

80.00 |

80.00 |

65.00 |

60.00 |

55.00 |

| Remark |

ALL THE DATA IS BASED ON LAB TEST FOR FIRST TIME EXPANSION IN CONTINOUS EXPANDER |

D Fast cycling Grade

| Specification |

D-103 |

D-104 |

D-105 |

D-106 |

| Beads Size mm |

1.00-1.60 |

0.85-1.25 |

0.70-1.00 |

0.50-0.80 |

| Vol.Cont % |

6.54 |

6.29 |

6.01 |

5.85 |

| H2O % |

0.48 |

0.53 |

0.57 |

0.53 |

| Avg.size mm |

1.20 |

0.99 |

0.79 |

0.63 |

| Sieving ≥ 95% |

60.00 |

60.00 |

60.00 |

50.00 |

| Remark |

ALL THE DATA IS BASED ON LAB TEST FOR FIRST TIME EXPANSION IN CONTINOUS EXPANDER

|

|

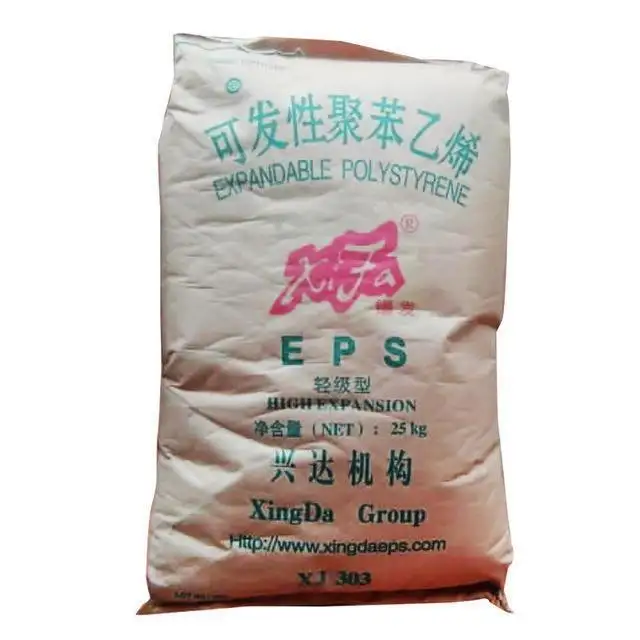

Packaging and shipping

The EPS series products of our company need to be put on the place where it is cool and ventilated, keep the storage temperature below 20°C in order to minimize the lost of frothing agents from escaping.

| 1 |

25kg/paper bag |

680 bags |

17 tons |

one 20feet container |

| 2 |

850kg/textile big bag |

20 junbo bags |

17 tons |

one 20feet container |

| 3 |

25kg/paper bag |

1020 bags |

25.5 tons |

one 40feet container

|

| 4 |

850kg/textile big bag |

30 jumbo bags |

25.5 tons |

one 40feet container

|

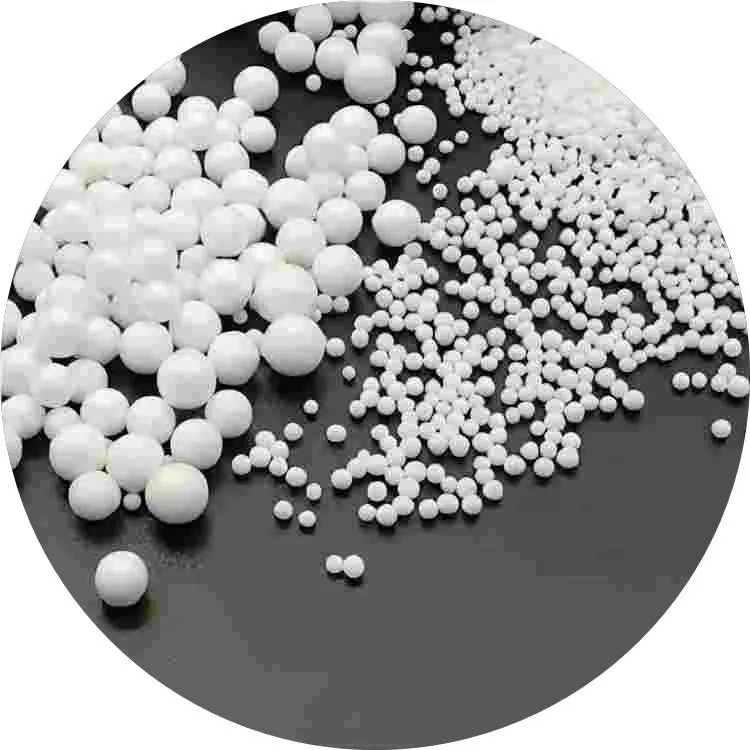

PRODUCT PHOTOS: