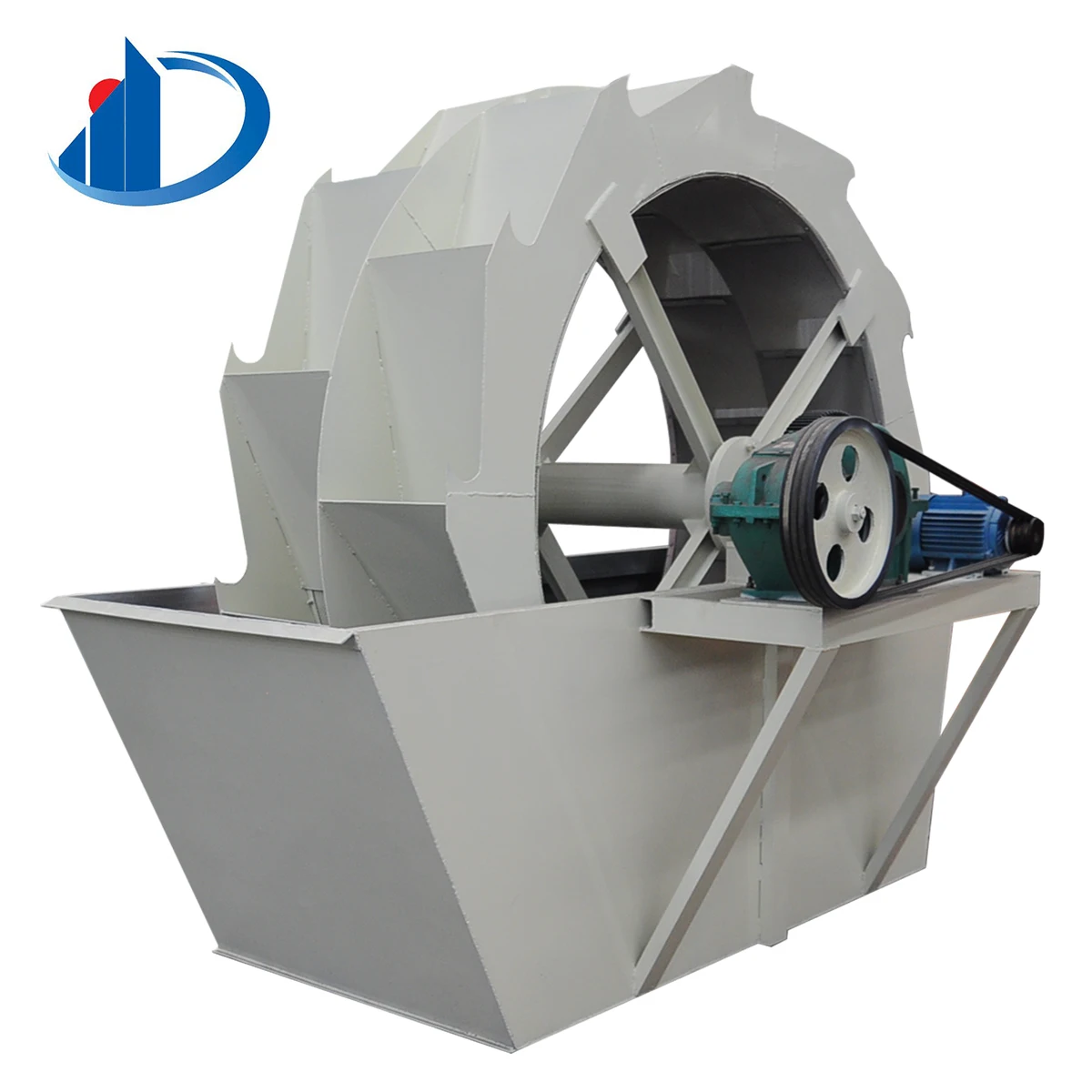

Мини-каменная дробилка цена от поставщика винтовая стиральная машина для

- Категории: Промыватель песка >>>

- Поставщик: Henan,Di,Hai,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Brief Introduction

Type: Necessary Equipment

Input Size: <10mm

Processed Materials: Limestone, calcite, barite, dolomite, potassium feldspar, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, coal, ect.

Applications: Cement, Coal , power plant desulfurization, metallurgy, Chemical Industry, non-metallic mineral, construction material, ceramics.

Features

1. Simple structure.

2. The bearing device of impeller drive is separated from water and 1 materials with water, to avoid the damage of the bearing.

3. New sealing structure and reliable transmission device.

4. Reasonable structure.

5. High capacity, low power consumption.

6. Easy structure, stable operation.

Technical Parameter

| \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t |

1.Screening Cloth is made of high abrasive material, which prolongs the service life.(Polyurethane material also can be used) Except the screen cloth, there are not any other wear parts in the vibrating screen.

2. Bearing are Produced by the largest manufacturers nationwide(ZWZ)SKF also can used.

3.Gear reducer:The complete transmission device including bearings are all separated from water, which avoid the damage of bearings caused by water,sand and any other pollutants.

4.Pulley: It is made of wearable and anti-corrosion materials, Improved the transmission efficiency.

Principle

1.When the machine works, the motor drives the impeller run slowly after being decelerated by v-belt, reducer and gear.

2.The sand enters the wash trough through feeding tank, rolls pushed by the impeller, and rubs mutually to remove the impurities covering on the surface of the sand, it breaks the water vapour which favors dewatering;

3.At the same time, the strong water flow takes the impurities away, and discharged from the overfall.

4.The clean sand is taken away by the impellers, when rising, the water drops down to the wash trough from the nets, this can both dewater the sand and save water.

5.Finally, the sand is poured into the discharge chute and finished cleaning.

1)All the wear out spare parts are packed by plastic films and wooden boxes.

2)Wire cables are used for fastening the machines.

3)FCL: Shipping by standard exporting container.

4)LCL: Poly wood case.

Contact Information

Name: AmyZhang

Tel: 0086-371-67103298

Mobile: + 86 158 9062 6237

WhatsApp: +8615890626237

WeChat: 158 9062 6237