Автоматическая машина для розлива питьевой минеральной воды в бутылки 12000BPH производственной

- Категории: >>>

- Поставщик: Zhangjiagang,City,New,Crown,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Application

The mono-bloc machine is integrated with rinsing, filling and capping together;

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays water to rinse bottle in wall.

| \t | \t | \t | |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

Main Features

1. Washing,filling,capping can be carried out on the same machine. The design of the machine is scientific and reasonable.

2. The water filling machine appearance is beautiful and the function is complete. The operation and maintenance is convenient.

3. The water filling machine adopts advanced technology and normal pressure filling valves, with high filling precision.The speed of filling is fast and the liquid amount is controlled accurately,with same filling level.

4. The water filling machine filling device can be stopped automatically whne there is no bottle or bottles are damaged.

5. Pneumatic value and damped gears are used for bottle conveying, the noise is low and the whole machine runs smoothly.

6. The magnetic torque is used for screw capping.The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed. The caps can not be damaged, the capping is reliable.

bottled drinking water plant

Machine Parts

Name: Rinsing Part

Except the down framework, the transmission parts and some parts that must be made of special materials. Other spare parts are made of stainless steel 304.

The gripper is made of stainless steel, the position where hold the bottleneck is also made of stainless steel, compared with the traditional rubber gripper, it is much hygiene, durable, and no quick-wear parts, the screw parts of the bottleneck can avoid being polluted by the rubber gripper.

Machine Parts

Name: Filling Part

The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of 304 stainless steel.

Machine Parts

Name: Capping Part

Introduce most advanced cap sealing technology called France "ZALKIN ". With the help of expert from institute of electro mechanics and mechanical engineering of Shanghai Communications University, we successfully designed. For example: I) the screwing capping head cam (the main parts which can assure the machine run stationary), while adopting "ZALKIN" technology, the expert improve the authenticity and stability of the machine focused on dynamics and kinematics. II) Screwing capping head (the main parts which can assure the capping quality)

Complete Drinking Water Production Line Flow Diagram

Water Treatment Part

Stainless steel 304 material

Automatic PLC+Touch Screen Control

Water Filling Part

1, The water filling machine filling device can be stopped automatically whne there is no bottle or bottles are damaged.

2, Pneumatic value and damped gears are used for bottle conveying, the noise is low and the whole machine runs smoothly.

3, The magnetic torque is used for screw capping.The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed. The caps can not be damaged, the capping is reliable.

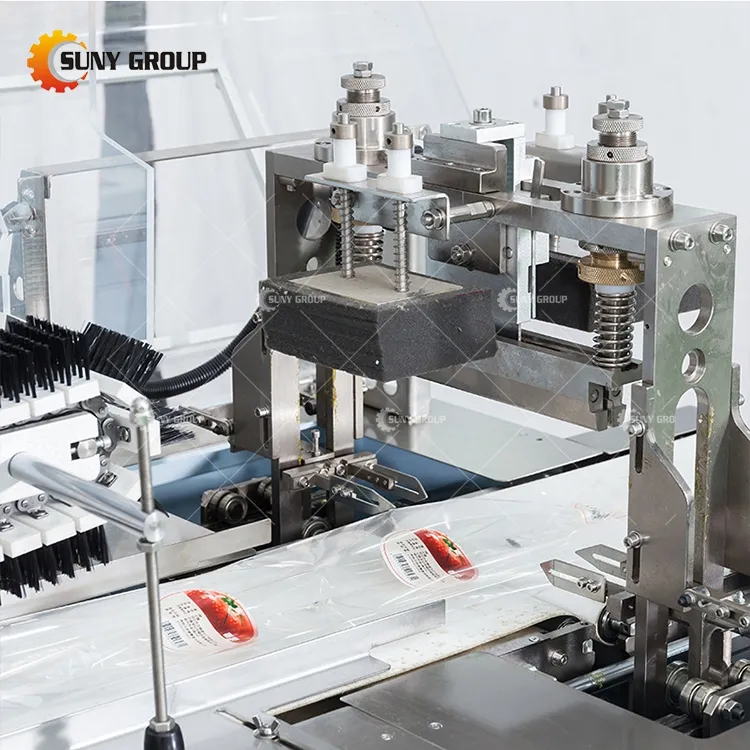

Labeling Machine

Heat Shrink Sleeve Labeling Machine/OPP Hot Melt Labeling Machine/Adhesive Sticker Labeling Machine,with various types of label design,stably and rapidly.

Packing Machine

Semi-automatic PE Film Shrinking Machine/Automatic PE Film Shrinking Machine/Dropping type/catching type carton boxing system/one-piece hot melt glue carton boxing system

Zhangjiagang New Crown Machinery Co.,Ltd.

Since its establishment in 1997, Zhangjiagang New Crown Machinery has been dedicated to the production and research of beverage machinery. At present, Zhangjiagang City New Crown Machinery can provide filling machines for water, juice, carbonated drinks, beer and other liquids. In addition, Zhangjiagang New Crown Machinery has many patents such as glass bottles and PET bottle filling machines.

Q: How to get an appropriate offer from New Crown Machinery?

A: Please inform us:

1, production capacity per hour/per day/per month ... ...

2, filling liquid: water, juice, carbonated drink, beer or ... ...

3, bottle type: plastic bottle, glass bottle, can or ... ...

4, cap type: screw cap, crown cap, can lid or ... ...

5, for water treatment, it's better offer us the raw water quality report ... ...

Q: What can I do if I haven't gotten any clue of the production line? I just wanna open a factory and to do the business.

A: Don't worry about this; You can inform us:

1, the exact production you wanna deal with;

2, the budget of the production line; If no budget of the business, I will send you the popular machine in our factory for your ref;

3, we will help tp design everything including the machine layout and factory layout;

Q: This is the first time I cooperate with your factory. How can I trust you about the machine quality?

A: Before ordering the machine, we will make the offer very clear. For example, the material thickness, the brand etc. We can have the video call and I will show what we have in the factory;

Also you can visit us to see the machine;

Q: If the quality doesn't meet my requirement, how can you solve this problem?

A: Before ordering the machine, we will negotiate the machine inspection standard. Then start production; If you are not satisfied with the quality, show us, we will re-do it before shipping;

Q: Can I run the machines in your factory if I buy the complete line in your factory?

A: Sure, why not. We will have the line connected and tested in our factory before shipping even you didn't mention; We will make it working before arriving at your factory;

Q: How can I get the machine?

A: Our company have the export license, so we can help to ship the machine to discharge port that you are available.

Q: How can I install the machine and commissioning? Do you have the technician to my factory?

A: We have the technician available to your factory for machine installation and commissioning; BUT client should be responsible for the round-way flight tickets, technicians' daily salary, local transportation, local hotel and eating.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Water treatment system

91.8% Response Rate

300BPH 5 gallon production line

91.8% Response Rate

Carbonated drink filling machine

91.8% Response Rate