Лучшие цены завод по переработке отходов шин линейное оборудование для резиновых

- Категории: Другое оборудование для обработки резины >>>

- Поставщик: Henan,Baishun,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Best prices waste tyre recycling plant rubber granules line machinery

Product Application

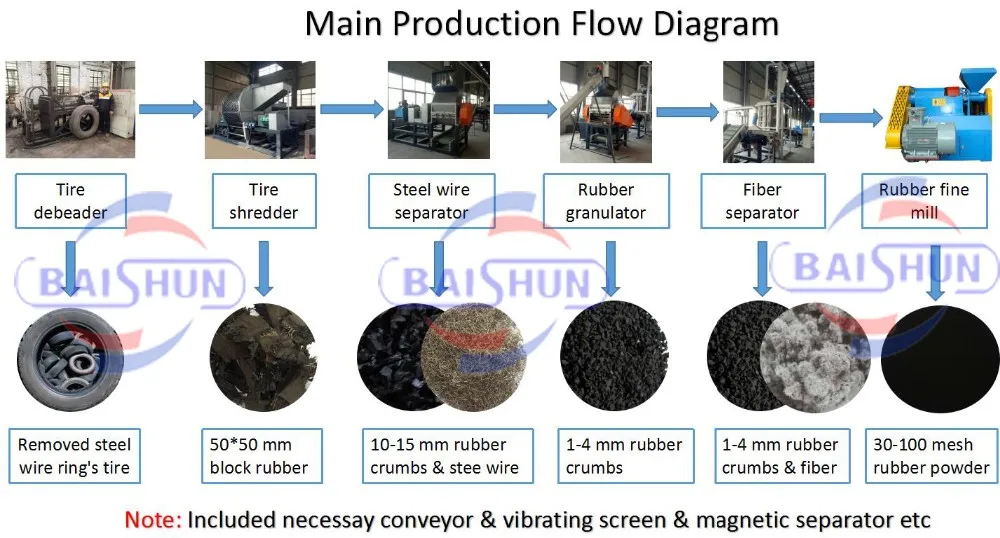

Tire recycling production line ( waste Tire Shredder Machine ) is used for recycling the scrap tires, (either nylon tires or radial tires ) to get rubber crumb. The steel wire can also be separated from the tires and sold to the market and make profit.

The finished rubber granules and rubber powder can be widely used in stadium runway, school playground, modified asphalt and also can be made into rubber pipe, rubber overshoes, rubber conveyor belt, rubber floor tile and deceleration strip by high temperature and high-pressure desulfurization.

Best prices waste tyre recycling plant rubber granules line machinery

1) Long life using, high utilization, multiple maintenance ;

2)The rubber crumbs, steel and fiber can be separated automatically ;

3) PLC control system, simple and easy to control and maintain ;

4) Only need 3-5 persons to operate the machine, reducing labor cost ;

5) Iron/steel removing ratio>99.5%, fiber removing ratio>98% ;

6) We have already received the international certificate CE, ISO .

Machine Parts tire recycling plant machinery

Name: Steel wire drawing machine

Motor power: 11kw

Function: Pull out the steel wire from the sidewall, when remove the steel wire, it can protect the blades of tyre shredder, prolong the service life of the blade and increase the working efficiency of the shredder.

| \t | \t | \t | \t |

| \t | \t | \t | \t |

Name: Tire shredder machine

Motoer power: 75kw*2

Blade materials: H13

Function: Crushing whole tire into small pieces 30-80mm blocks for further processing;

Features: Electronic control system is for PLC programming with start, stop, forward, inversion and overload automatic protection function.

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

Name: Steel wire separator machine

Motor power: 55kw

Blade materials: D2

Function: Cut the rubber (size:50*50mm) into rubber granules (size:10-15mm) and separate the steel wire out from the rubber with steel wire

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

Name: Rubber granulator

Motor power: 75kw

Blade material: D2

Function: It is used to crush the rubber from the steel wire separator and the particls size can reach 1mm after crushing, then they can reach the final size by particle sieving and circulation

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

Name: Fiber separator

Motor power: 11kw

Function: It is mainly applied to separate the nylon fiber from the mixture of rubber powder and nylon fiber, and then get pure rubber powder. It is separation can reach above 99% .

Name: Fine grinder

Motor power: 22kw*3+0.75kw*3+5.5kw

Function: The fine grinder is applied to crush rubber powder or rubber granule into more smaller size and it can reach 100mesh or more smaller

Shipping: Within 10 days after receving the deposit

Container: Usually 3 pieces 40GP container will be okay.

Plastic crusher machine

Mainly crushing waste pet bottle, plastic head, cardboard, plastic boxes, ABS, PMMA, POM, PU, PP, PE, PVC material etc

Plastic shredder machine

Mainly shredding waste plastic film, woven bag, plastic agricultural film, snakesin bag, space bags, woven bags and so on.

Multifunction shredder machine

Mainly shredding waste plastic boxes, cartons, cans, paint bucket, rubber, various waste metal etc

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 7*24 hours after sales service