Молибденовый

- Категории: Molybdenum >>>

- Поставщик: Luoyang,Advanced,Refractory,Metals,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

molybdenum bar

Specifications: 99.95%Molybdenum products.

1. Purity: molybdenum> =99.95%

2. Density :>=10.2g/cm3

3. Properties: Recrystallization temperature between 1500 and 1700

4. Elongation: 15%-20%

5. Specification: according to the needs of users. The concrete specification and shape could be consulted by both parties, such as molybdenum boat, molybdenum crucible, molybdenum barrel, molybdenum tube, molybdenum mandrels, and molybdenum rod and so on.

Grade | The impurity content is no more than % | |||||||

Fe | Ni | Al | Si | Mg | C | N | O | |

Mo-1 | 0.01 | 0.005 | 0.02 | 0.01 | 0.002 | 0.01 | 0.002 | 0.008 |

Mo-2 | 0.01 | 0.005 | 0.02 | 0.01 | 0.002 | 0.01 | 0.002 |

|

Production Name | Molybdenum Rod |

Standard | GB/T17792-1999 |

Density | Mo>=99.95 |

Purity | 10.2g/cm3 |

Application | Molybdenum rod can be stretched into molybdenum wire, molybdenum electrode and it also can be applied to steel-making additives, Electric vacuum parts, gas pipes, lead-wire, pole, side bar, daily-use glass, optical glass, insulation material and glass fiber |

Surface Finish | Black Surface - Surface is "as swaged" or "as drawn"; retaining a coating of processing lubricants and oxides. Ground - Surface is center-less ground to remove all coating and to achieve precise diameter control. |

Dimension | 16>Diameter>0.8xL(mm) |

Size details:

| Diameter | Diameter Tolerance | Length | Tolerance | Length | Tolerance |

| 2~6 | +/-0.03 | 20<L<200 | 0, +0.5 | >=200 | 0, +1 |

| 7~30 | +/-0.05 | 20<L<200 | 0, +0.5 | >=200 | 0, +1 |

| >30 | +/-0.1 | L>=200 | 0, +1 |

Tolerance Details:

| Diameter | Diameter Tolerance | Length Tolerance |

| 2~15 | 0, +0.2 | 0, +1 |

| 16~40 | 0, +0.3 | 0, +1 |

| >40 | 0, +0.5 | 0, +1 |

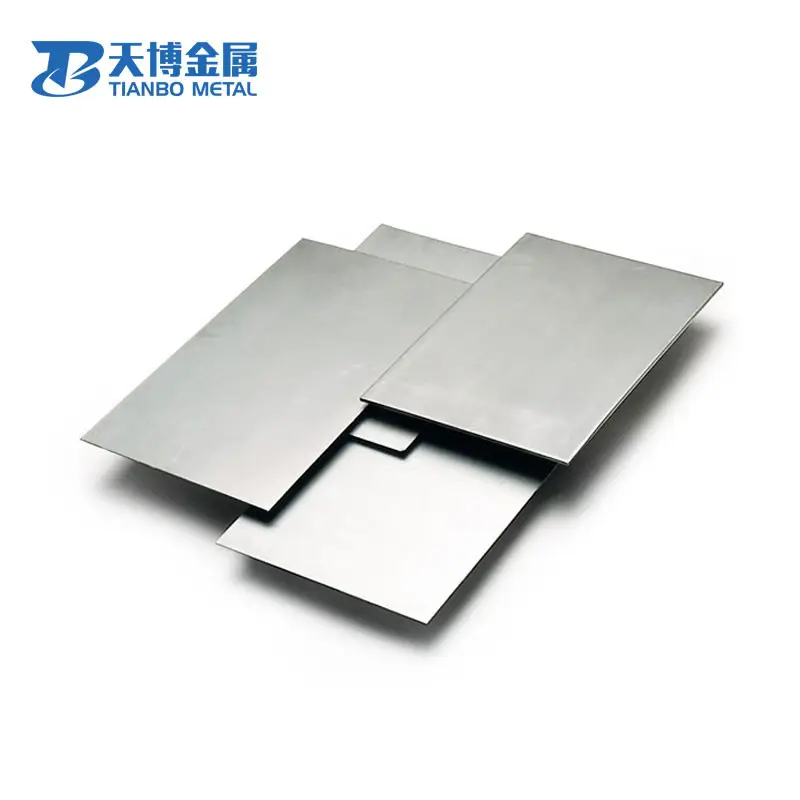

Products Show

Customer Show

We offer material composition sheet and examination report which include density, flaw detection, dimensions and so on. Our products are packed in plywood case with expanded plastic. What's more, the case is moistureproof and grooved for products being placed stably.

We have 15 years experiences in producing and saling qualified Refractory metals to our customers

Production equipments Test Euipments

Test Euipments

Contact details

Contact details