Горячая Распродажа малая машина для извлечения кокосового масла/экстракта

- Категории: >>>

- Поставщик: Henan,Huatai,Cereals,And,Oils,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

coconut oil extract machine

Technology:

We have strong Research & Development team. We have obtained 23 patents and won hundreds of honors.

Coconut is palm tropical woody oil material,Coconut pulp after drying is copra, the moisture content down to 6% -10% ,copra fat is 57% -75%, copra meal after extracting coconut oil can be used as animal feed. Coconut flesh can also be processed into coconut powder, copra and other foods.

coconut oil extraction production line mainly includes pretreatment - extracting oil - refining oil .

coconut oil extraction production line main include crushing section, steaming and roasting station, oil press, degumming section, deacidification, decolorization section, deodorizing section.

coconut moisture should be controlled between 7% -10%, or not conducive to copra oil extraction.

Henan Huatai coconut oil extraction machine has the following advantages:

1, Relatively low energy consumption, long service life, can be the greatest possible for customers to create profits;

2, To minimize the loss of coconut oil, increase the oil yield, improve production quality, improve the quality of coconut oil and meal.

Pretreatment Process of coconut oil extraction machine:

coconut → cleaning → crusher → cooking →pre-press → twice pressing → crude oil

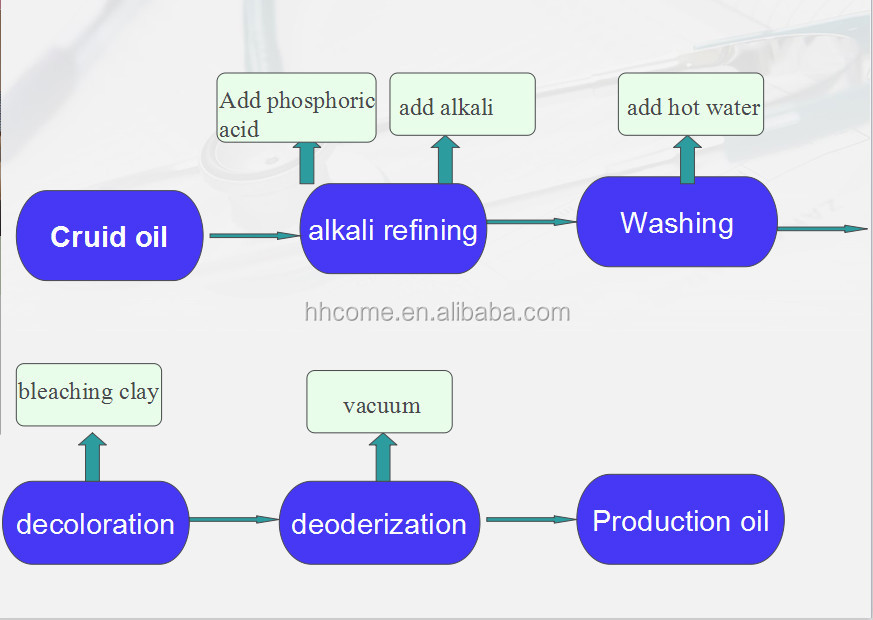

Coconut oil refining basic process of coconut oil extraction machine:

coconut crude oil → filtration → deacidification - degumming → decolorization → finished coconut oil

Coconut oil refining flow:

Main equipment:

Neutralizing tank: using for acid refining, alkali refining and washing;

Decolorizing tank: using for bleaching oil and removing pigment;

Deodorization tank: using for removing the odour of oil

Heat transfer oil furnace: providing the heat energy during producing, the temperature can reach to 280℃;

Vacuum pump: providing the vacuum level when decolorizing and deodorizing, can reach above 755mmHg;

Air compressor: to dry the bleaching clay, and press the product oil;

Filter: to filter the bleaching clay

Steam generator: to produce the steam when steaming and deodorizing.

small coconut oil extraction machine

small coconut oil machine advantages:

1.High oil yield,low residual oil rate of meal

2.Low labor intensity

3.Good working environment

4.Excellent oil quality,Good meal quality.

Huatai Machinery, the full name is Henan Huatai Cereals and Oils Machinery Co., Ltd. Located in Hua County industry Zone of Henan Province. Covering an area of 150,000 sqm, with total investment RMB360 millions, has a modern standard plant and advanced processing equipment, is a research and development, design, manufacture, guidance, installation as one of the major cereals and oil machinery manufacturing enterprise.

Rich experience of large overseas projects

- Hundreds of successful overseas projects;

- Rich experience in government bidding projects;

- Products are exported to all over the world;

- Large project experience, can undertake 3,000t/d projects;

Dozens of certificates and honors

- Won Gold Award of China Invention Exposition;

- Excellent member of China Grain & Oil Association;

- Won the Provincial trustworthy unit for many years;

- China Top 10 Food and Oil Machinery Brand;

Sudan | 30T/D Peanut Oil Pressing and 15T/D Peanut Oil Refinery Project in Sudan |

Ethiopia | Ethiopia 30T Sesame Oil Mill Machine |

Egypt | 2015 Henan Huatai Singed 100TPD Soybean Pretreatment and Soybean Oil Extraction Equipment With Egypt Customer |

Swaziland | 2015 Henan Huatai 30T Soybean Oil Refining Equipment Sent to Swaziland |

Nigeria | 2015 Henan Huatai Singed 50TPD Peanut pretreatment and 15TPD Peanut Oil Refining Equipment With Nigeria Customer |

Russia | 2015 Henan Huatai Singed 50TPD Soybean Oil Production Line With Russia Customer |

Ethiopia | 2015 Henan Huatai Singed 50TPD Fully Continuous Sunflower Oil Refining Equipment With Ethiopia Customers |

Uzbekistan | 2015 Henan Huatai Singed 50T oilseeds pretreatment and oil extraction and oil refining with Uzbekistan Customer |

Nigeria | 2015 Henan Huatai Singed 20T Semi-continuous Palm Oil Physical Refining Equipment With Nigeria Customer |

Peru | 2015 Henan Huatai Palm Oil Physical Deacidification and Deodorization Equipment Sent to Peru |