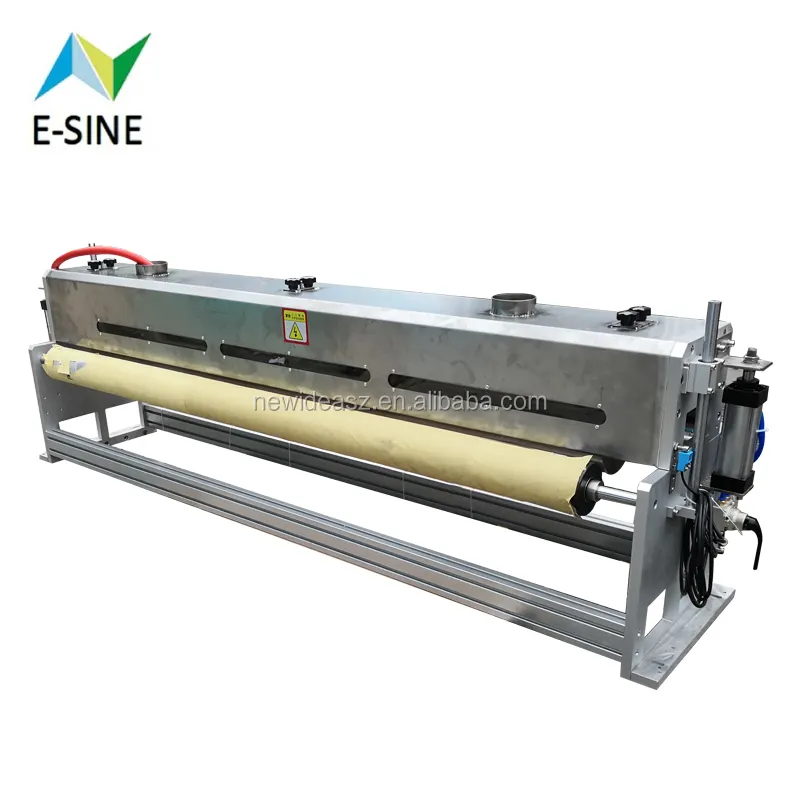

Оборудование для обработки коронавируса с пластиковой

- Категории: Other Plastic & Rubber Machinery >>>

- Поставщик: Shenzhen,Hefengjiada,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Plasma surface treaters,atmospheric plasma surface treaters ,plasma treaters for effective

| model | input voltage/frequency | woring frequency | output power | treating wih | air source |

| FR50BR | AC220/230V±10% 50/60Hz | 22.5KHz | 300-600W | 30-50mm | 0.4Mpa no water |

FR50BR Plasma treatment equipment advantages

1. Increase the bonding strength: after plasma treatment can increase the material's surface tension and makes water-based glue more permeable, enhance box bond strength from the surface to improve the quality of products.

2. Wide application: can be used to paste box gluing machine, auto lamp shell glue, glue car seal, etc

3. Efficient: online processing per minute up to 300 m/min, and pasting box machines, wire can be used, greatly improve production efficiency;

4. Enhance transparency: compared with the traditional grinding wheel, don't leave any traces in the material surface after treatment, and does not produce dust, enhance the aesthetic surface, at the same time to strengthen the printing process;Safety and health, suitable for food, medicine and other packaging industry.

5. Use time and long service life: can online more than a month in a row, guarantee the need of the high strength work, at the same time, through the ISO9001 certification, CE to ensure the quality of use.

6. The use of low cost: electrical work continuously around only once every day, effectively reduce the production cost;

What is plasma application?

1. The printing and packaging industry:

Specifically for UV, laminating, glazing, such as all kinds of high polymer materials surface treatment;solve packing boxe

glue problems (such as toothpaste box, cosmetic box, cigarette case, wine box, electronic toy product box).Improve the work

efficiency, reduce the pollution of polishing and eliminate the paper pasting box machines powder pollution, save material,

save the cost of glue (using ordinary water-based environmental protection glue).

2. Digital industry:

Mobile phones, laptops and other digital products shell spraying, LOGO and decoration of the adhesive, screen of adhesive,

Increase the surface adhesion, prevent digital products shell to take off the paint and the keyboard words fade;

3. The car manufacturing industry:

For all kinds of rubber seals for car doors and Windows, interior trim, light, air conditioning wind device of local coating;Was

also used to increase the automobile brake block, wiper, oil seal, dashboard, the engine of the adhesive sealing, improve the

technology such as waterproof, sound insulation and prevent fall offa lot.

4. Hardware industry:

Metal spraying pretreatment of various steel by plasma surface treatment, to enhance the surface adhesion.After spraying of

metals, prolong the service life, its wear resistance compare without plasma treated increase more than 20 times.

5. Plastic industry:

Is mainly used in coating and adhesive pretreatment , the treated product surface not to drop paint, words don't fall off and fade.

Plasma machine applicate in glass and screen treatment

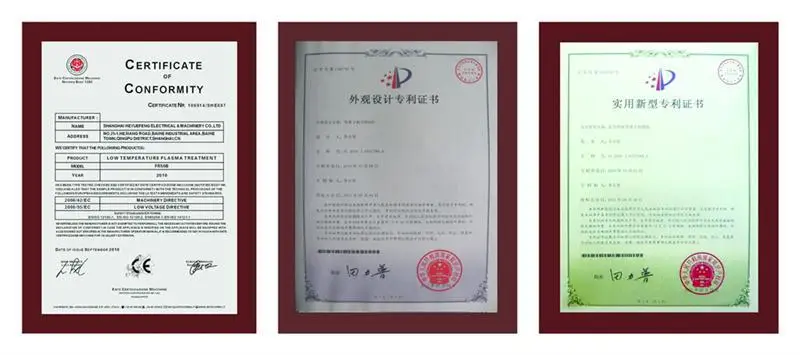

plasma certification

installation case

our advantages

1. 15years industry experience and excellent research team.

2 best quatity, best price and best service.

3,we have our own patented products amd some products get the international CE certification.

4.the corona are custom designed for each installation as required.

we provide good quatity and best service.we are continuously developing new corona and plasma equipment to help soving adhesion problems

HeFeng has been focused on the development and application of Corona surface treatment for about 13 years and continuously developing new equipments. we have abundant experience ,good quality , and best service to meet customer demands. Our main products are corona , plasma , dust cleaner, electrostatic eliminator , some corona accessory, UV curing system and electronic UV. Once you have printing and bonding problems, pls contact us !

Hefeng international exhibitions