Стандартная экспортная деревянная упаковочная машина для сухих пищевых

- Категории: Оборудование для производства кормов для животных >>>

- Поставщик: Jinan,Sunward,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

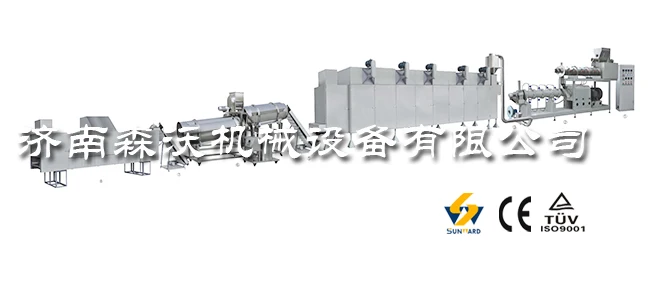

Standard export wooden case packing dry pet food machine processing Line

Pet food making machine is plant or animal material intended for consumption by dogs or other canines. In extruder, the ingredients are cooked under intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife.

1 Machines Configuration of Pet food making mahine :

1. Pet food raw material mixer.

2. Screw Conveyor

3. Animal feed extruder machine

4. Belt Conveyor(Air Conveyor)

5. Roasting Oven(Fryer Machine)

6. Flavoring Machine

2 Production Advantage of pet food making machine:

1. The motor of our extruder machine is Siemens Motor.

2. The raw material of pet food machines is Stainless Steel.

3. Our automatic pet food machines are controled by frequency changer, it is easy to operate.

4. Our factory will send our engineer to install machines for you.

5. pet food processing line have the 12 months guarantee time.

6. Automatic pet food machine is multi-function. Many types of snacks can be manufactured by changing the die head and model. animal feed

3 .HOW IS PET FOOD MANUFACTURED ?

HOW DOES PET FOOD MAKING MACHINE PRODUCE PET FOOD?

- Typical raw materials used in pet food processing include cereal flour, vegetable proteins, minerals and vitamins and, in some cases, meat or fish flour and fresh meat.

- The dry ingredients enter the the pre-conditioner and are steam-hydrated. The counter-rotary twin shaft unit blends the ingredients and ensures proper mixing of steam, moisture and ingredients. Preconditioning produces partial gelatinization of starches and texturing of polymers

- The partially cooked mixture is then fed to the twin-screw extruder. Shearing, internal temperature, pressure, moisture and residence times are accurately controlled to achieve optimum starch gelatinization without loss of food quality. Liquids or steam may be injected through ports in the extruder barrel at various processing stages. Degassing is possible at this stage using a vent-stuffer.

- Granules are then shaped when they are extruded through the die. They are then put through a dryer, which reduces moisture (generally between 8 and 10%). The product is then coated, and flavoring and fat is added before cooling and packaging.

6 Pet food making machine technical parameter

| Model | Installed capacity | Real power | Output | Size |

| TSE65-P | 80KW | 50KW | 100-150kg/h | 2600*870*1950mm |

| TSE70-P | 90KW | 80KW | 200-260kg/h | 2700*870*19*50mm |

| TSE85-P | 110KW | 100KW | 400-500kg/h | 4000*1200*2200 |

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case for pet food making machine

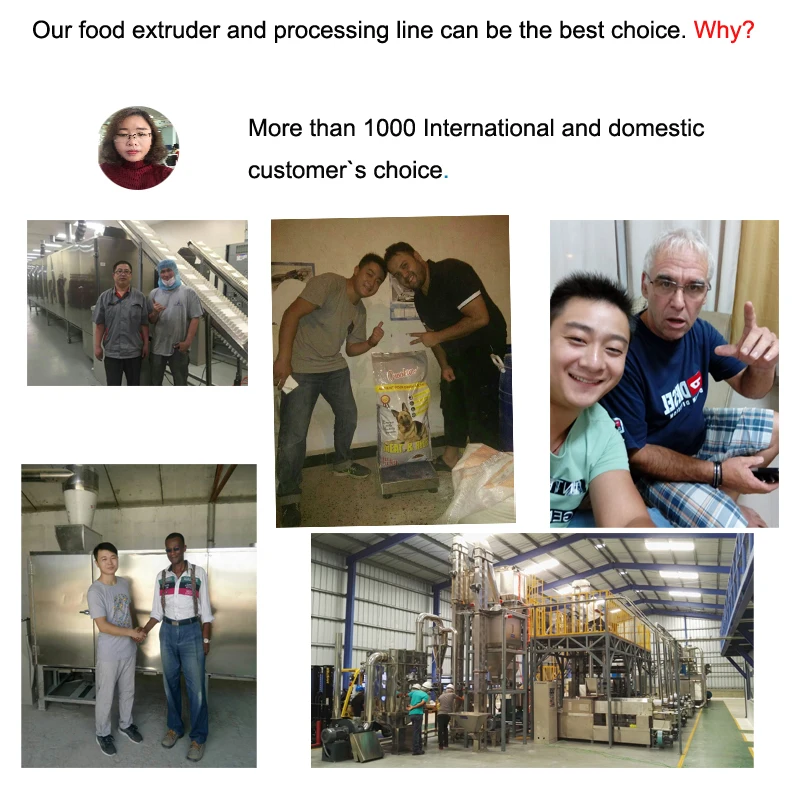

Leveraging our expertise in twin-screw and single-screw technology, we provide integrated turnkey extruder production lines, dryers and ancillary equipment to our customers.These reliable and innovative systems are mainly served for“Food & Feed“industry.

Sunward is constantly innovating through co-development partnership projects with its customers in every cooperation with our customers.The company, which has a strong quality culture and a commitment to responsible environmental action, is certified ISO 9001 and CE.

We provide local services to all our markets by offering our advice and expertise: spare parts and upgrading, equipment and ancillary modules, automation systems, training, process support and remote and on-site maintenance. Technical support is provided by a team of specialists.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service:

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

This production line can also produce other products. we just need to finish it by adjusting the mould from extruder .