High Level Amino Acids Pure and Organic Goat Milk

- Категории: Colostrum >>>

- Поставщик: BIOTARIS,BV

Поделиться:

Описание и отзывы

Характеристики

High Level Amino Acids Pure and Organic Goat Milk Powder

Manufacture of the Goat Colostrum Powder

Goat colostrum low temperature spray dried Pre-milk Powder that contains high level Amino Acids and Immunoglobulins. Yellowish powder from first and second milking of the goat, non-organic. BSE and IBR free, produced in France.

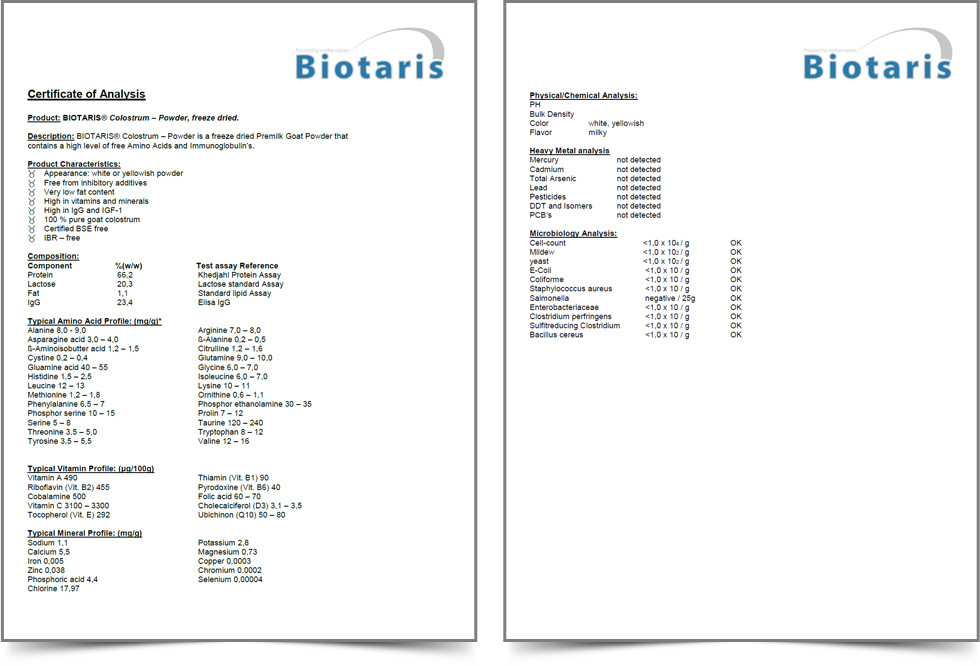

| Component: | % (w/w) | Test assay Reference |

|---|---|---|

IgG | 34 | Elisa IgG |

| Protein | 41.59 | Khedjahl Protein Assay |

| Fat | 24.02 | Standard lipid Assay |

| Carbohydrates | 25.80 | – |

| Ashes | 5.48 | – |

| Moisture | 3.16 | – |

| Made in France | – | – |

| Multilayer bag in export box | – | – |

Biotaris B.V. is a Dutch Company and supplier of high-end bovine and goat colostrum products for many years. By developing a special cold-state-manufacturing procedure for processing raw colostrum further in a loss-free and gentle way, our colostrum products exceeds the common quality standards.

Our suppliers are farmers from Germany, Austria and France. We believe that they have the most precious share in providing us with wholefood products that ensure our survival. This is especially true for organic farmers that, against all resistance, held fast to their philosophy that involves a considerable effort in extra work. Great credit is due to them personally for collecting this precious resource.

Manufacture of Colostrum

First of all, the liquid colostrum is degreased and after that directly deep frozen as it comes from the farm. Colostrum contains approx. 10% fat; therefore it would not be very digestible in its unprocessed form. The next step is the decaseination, in which those constituents are extracted from colostrum that are processed to cheese in a dairy factory. Colostrum whey remains that still contains such high-molecular elements that an immediate sterile filtration would be impossible.

For this reason the whey is micro filtrated so that only these constituents are left over that can pass the small pores of the filter. Those are the immunoglobulin’s (antibodies), growth factors, cytokines, interferons, interleukins, etc. Because bacteria are also very small, the sterile filter must not exceed a maximum size of 0.2 µ. Fortunately the protein molecules of the remaining ingredients are even smaller than the smallest bacterium. Afterwards it is refrozen to be freeze-dried.

In cold manufacturing, as it is used in our company, all ingredients survive processing. This procedure is a purely physical process, where neither chemicals nor other additives - except for one enzyme to separate the casein - are employed. We developed this procedure on the basis of the manufacturing techniques of biotechnology to protect the ingredients and to maintain their biological activity. Even the most sensitive ingredients like enzymes are preserved that way.

Colostrum is not only a highly nutritious functional food but it is also a substance that contains many life supporting and health promoting substances. The significance of Colostrum is best illustrated by the fact that most animals require Colostrum just after birth to survive. Some of these life supporting and growth promoting substances are as follows: antibodies, immune factors, growth factors, attachment factors, cytokines, oligosaccharides, essential fatty acids, and phosphides. The remarkable thing about Colostrum is that all these substances act synergistically in such a way as to enhance the overall effect of each individual component.

From the collection up to processing of colostrum, there are huge quality differences. Profound knowledge and a specific employment are needed to treat such vital and delicate product in the correct manner to ensure keeping the vitality of colostrum.Supplied by certified farms, exclusively from Germany, Austria and France

⇒ Collecting points with freezers

⇒ Clean collecting tanks and documentation of CT

⇒ Colostrum is frozen directly after milking

⇒ Collection by freezer lorry1. and 2. milking only, that means the first 12 hours

⇒ Specifically developed and patented cold processing procedure, does completely without heating

⇒ Bioactive substances are kept for 100% by using the latest and most gentle technologies

⇒ Due to the special treatment, it contains the natural enzyme telomerase! in the final product! as well

In the end, a gigantic combination of active ingredients results with free, vivid, and low-molecular vital substances (immunoglobulin’s, growth factors, proteins, vitamins and minerals). Biotaris and our suppliers have many years of experience in the production of high quality colostrum. In cold manufacturing, as it is used in our factories, all ingredients survive processing. For that reason we can guaranty you the best available quality in the market.

| Copyright © 2019. BIOTARIS BV. All Rights Reserved | Product Ranking Service by Opal Infotech |

|---|