Чистый уменьшенный железный

- Категории: Iron Powder >>>

- Поставщик: Gongyi,Yalv,Material,Co.,Limited

Поделиться:

Описание и отзывы

Характеристики

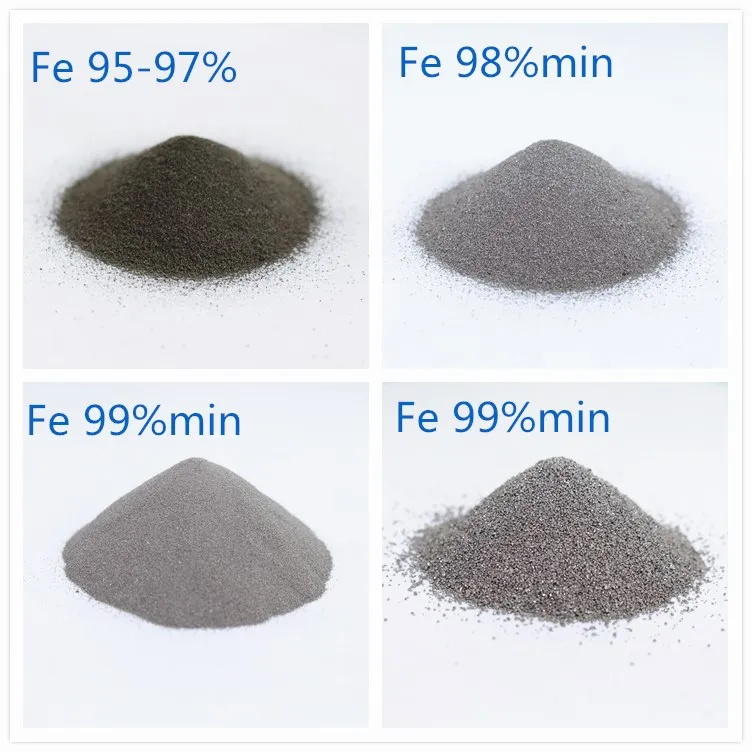

Lowest Price Pure Reduced Iron Powder

Iron powder is one of the most important metal powders in the powder metallurgy industry. The largest amount of iron powder is used in powder metallurgy production. The consumption of iron powder accounts for about 85% of the total metal powder consumption.

Iron powder used in the production of powder metallurgy iron-based products of iron powder, its quality indicators include: general chemical components, such as iron, carbon, oxygen, sulfur, phosphorus and acid insolubles content, oxygen content available hydrogen loss (loss weight) of the reduction in hydrogen approximately;Physical and technological properties, such as size composition, loose packing density, fluidity, compressibility and sintering dimension stability.Such as high density, high strength as manufacturing machinery parts, oxygen content of iron powder and compressibility (iron powder was pressed in certain pressure can reach the compact density) indicators have strict requirements.Reductive method and atomization method have been able to produce low oxygen content and high compressibility of high quality iron powder.

Iron powder specification:

Our wide range of powders with varying chemical and physical properties can match your requirements very well.

ITEMS | Unit | reduced iron powder | reduced iron powder | water atomized iron powder | |

MFY85 | MFY97 | MFY98 | MFY99 | ||

Fe | % | 85-90 | 97 | 98-98.5 | 99-99.5 |

C | % | 0.03-0.04 | 0.01-0.03 | 0.006-0.01 | |

P | % | 0.02-0.03 | 0.02-0.03 | 0.007-0.01 | |

S | % | 0.02-0.03 | 0.02-0.03 | 0.008-0.01 | |

Mn | % | 0.3-0.4 | 0.22-0.28 | 0.10-0.15 | |

Si | % | 0.2-0.3 | 0.15-0.20 | 0.15-0.20 | |

HL | % | 0.3-0.5 | 0.01-0.03 | 0.15 | |

Hydrochloric acid | % | 0.3-0.5 | 0.02-0.04 | / | |

Bulk density | g/cm3 | 2.2-2.4 | 2.6 | 3.0-3.1 | |

Flowability | S/50g | 30-35 | 30-35 | 26-27 | |

Compressibility | g/cm3 | 6.3-6.5 | 6.5-6.7 | 7.0-7.2 |

Welding Rod Iron powder | Ordinary Iron Powder | Cutting Easy Iron Powder | Partially AlloyedSteel Iron Powder | Valve Seat Iron Powder | ||||||

MYT09 | MYA10 | MYA12 | MYA15 | MYA16 | MYA18 | MYA20 | ||||

Bulk density | g/m³ | 3.0-3.8 | 3.0±0.1 | 2.70-3.05 | 3.0±0.1 | 2.90-3.15 | 2.90-3.15 | 3.20-3.40 | ||

Flowability | S/50g | ≤30 | ≤33 | ≤30 | ≤33 | ≤33 | ≤40 | |||

Compressibility | g/m³ | |||||||||

600MPa | ≥7.05 | ≥7.05 | ≥7.05 | ≥7.05 | ≥6.80 | |||||

500Mpa | ≥6.70 | |||||||||

Fe | % | ≥98 | balance | balance | balance | balance | balance | balance | ||

C | % | ≤0.03 | ≤0.02 | ≤0.02 | 0.02-0.8 | ≤0.02 | ≤0.02 | 1.7-1.9 | ||

P | % | ≤0.02 | ≤0.015 | ≤0.02 | ≤0.015 | ≤0.02 | ≤0.02 | ≤0.02 | ||

S | % | ≤0.025 | ≤0.025 | 0.20-0.45 | 0.025-1.5 | ≤0.025 | ≤0.025 | ≤0.03 | ||

Mn | % | ≤0.25 | ≤0.15 | 0.1-0.45 | 0.15-1.5 | ≤0.15 | ≤0.15 | ≤0.5 | ||

Si | % | ≤0.10 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.3 | ||

Ni | % | 1.60-1.90 | 3.50-4.20 | 1.20-1.40 | ||||||

Mo | % | 0.40-0.55 | 0.40-0.55 | 3.00-3.80 | ||||||

Cu | % | 1.40-1.60 | 1.40-1.60 | |||||||

Cr | % | 3.50-4.00 | ||||||||

Co | % | 5-6 | ||||||||

O | % | ≤0.15 | ||||||||

HL | % | |||||||||

Hydrochloric acid | % | |||||||||

particle size distribution | %, μm | |||||||||

>180 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | ||||

180-150 | <10 | <10 | <10 | <20 | <20 | <10 | ||||

150-63 | balance | balance | balance | balance | balance | balance | ||||

<63 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ≥25 | ||||

Iron powder application:

1. Powder metallurgy products;

2, welding electrodes, improve the deposition efficiency;

3, cutting stainless steel iron, improve the cut thickness;

4, chemical iron powder, used as a chemical catalyst, precious metal reduction, alloy addition, copper replacement;

5. Iron powder for metal replacement, used in copper and nickel smelting and processing industries to replace metals;

6, iron powder crafts fill weight, used to increase the imitation of metal craftsmanship effect and weight;

7, Iron powder for sewage treatment, used for electroplating, leather, paper, chemical, ceramics and other industries wastewater treatment;

8, iron powder for heating, for warm bags, heat posts and so on.

Packaging:

10KG/ package,25KG/ package,50KG/ package,25 kg / barrel,50 kg / barrel etc.... Or as customers' requirement.

Shipment:

1. As for the tiny amount(less than 50kgs), we will use express(TNT, FedEx, EMS or DHL etc), which is convenient.

2. As for the small amount (from 50kgs to 1000kgs), we will deliver by air or by sea.

3. As for the normal amount (more than 1000kgs), we usually shipped by sea.

Gongyi Yalv Material Co.,Limited

Gongyi Yalv Material Co., Ltd is a production and sales manufacturer with over 100 employees.It is located in Gongyi Science & Technology Industrial Zone.The company is mainly engages in the production of refractory material, abrasives and water treatment materials.Porducts are Reduced Iron Powder, Atomized iron powder, sponge iron, brown fused alumina, white fused alumina,Walnut shell, silicon carbide, boron carbide, Poly aluminium chloride(PAC), Polyacrylamide(PAM),Coconut shell activatedc carbon, Phosphoric acid, Aluminum dihydrogen phosphate,Potassium aluminium fluoride,Sodium hexafluoroaluminate(Cryolite), Aluminium fluoride, Sodium hexametaphosphate, etcThe capacity of the company is more than 200.000 T per year.

100% factory manufacture and factory direct sales

We have more than 10 years of experience in producing metal powder.

We have ISO9001 quality management system certification.

We have a professional team and technical personnel, can solve all the problems you meet .

Our precision service has won the praise of customers. We have long-term cooperation with these customers.

We are hoping to cooperate with partners in global market to creat win-win business.

Q: Payment term:

A: T/T, Western Union, Money Gram, PayPal; all could be acceptable with discussion.

Q: Delivery Time:

A: If the size we have storage, could delivery within 3 days. If the size you need haven't storage, production time would be 7-15 days based on our production schedule.

Anyway, would try best to delivery our products as earlier as possible with your requirements!

Q: MOQ:

A: Even 1 kg is possible!

Q: Package Information:

A: 20kg/inner thick plastic bag, further put it into wooden barrel or paper bag or as customer's request!

Q: The nearest port of our factory:

A: Tianjin and Qingdao port! Also could send products to any port you need my dear Customer~

Q: The time for deliver ourproducts to Tianjin or Qingdao port:

A: 1-2 days.

Q: How to insure the quality and quantity of our product?

A: We have ISO9001 certificate for our whole production. Own high technical professional lab.

Before delivery, we would send our products to the Third Party Lab for last test too.

And we buy Official Insurance for every shipment!

If you are interested in our iron powder . Any more inquires, please let us know., best price and free samples will be sent to you right away!

Click following to start inquiry ☟