Аппарат для вакуумного покрытия стекла с магнитным

- Категории: Станки для электроосаждения металла >>>

- Поставщик: Ningbo,Junying,Vacuum,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

| Glass Multiole Arc Ion Vacuum Plating Machine |

Specifications

1.Plc Easy to operate

2.Can be customized

3.High quality

The bathroom sanitary ware/gas cover glass coating machine/Hard chrome PVD metallizing machine

A, JYC - 1824 magnetron sputtering coating equipment configuration and the main parameters

1, the vacuum chamber:

(1), inner cavity dimensions: length * width * height = 2400 x520x1800mm

(2), manufacturing materials: high quality 304 wall thickness 10 mm stainless steel materials

(3), the structure form: vertical before the door box-type structure (including well type stiffener, vacuum pressure can resistance - 7)

(4), watch window: with 1-2 observation window, the door in the middle, with manual shutter, convenient observation sputter ion source working condition.

(5), lining plate: random user with a set of glass fiber reinforced plastic lining plate, sliding straight insert structure, convenient cleaning.

6, locks: manual lock. Frame x80mm 40 gb A3 carbon steel.

2, artifacts: workpiece frame with a set of guide rail type, material is stainless steel.(workpiece increase one set)

3, vacuum extraction system:

(1), diffusion pump and one machine production in shenyang KT - 800 high vacuum oil diffusion pump, with cold trap and pumping speed, low return rate.

(2), roots pump: match made ZJP - 1200 Shanghai roots pump station

(3), mechanical pump: chengdu two 2 x - 70 rotary vane pump plunger pump (or 150 a)

(4), maintain pump: chengdu 2 x - 30 rotary vane pump station

(5), vacuum valve: adopt pneumatic stop valve, cylinder is a professional manufacturer of famous brand products, brands combined electromagnetic directional valve group, imported pneumatic sealing element

6, pipeline and shock absorption form: vacuum pipe, valve manufactured A3 carbon steel.The pipeline vibration is made of stainless steel bellows.

All landowners, throttle valve, vacuum system with throttle valve, guarantee the stability of coating vacuum chamber during the process of vacuum degree, improve the uniformity of coating.

Share a set of 4, the coating way: sputtering cathode gyration gumming, middle parallel moving (plus rod and screw, corrugated pipe water).

Cylindrical magnetron target (target 56 mm long, 70 x 1600 x diameter diameter), high purity, target material utilization rate is high, high coating uniformity, dc power supply (a) 50, giving a target inside the magnet.

5: in the form of cooling, the input part of indirect water cooling.(diffusion pump and target material need cooling water circulation).

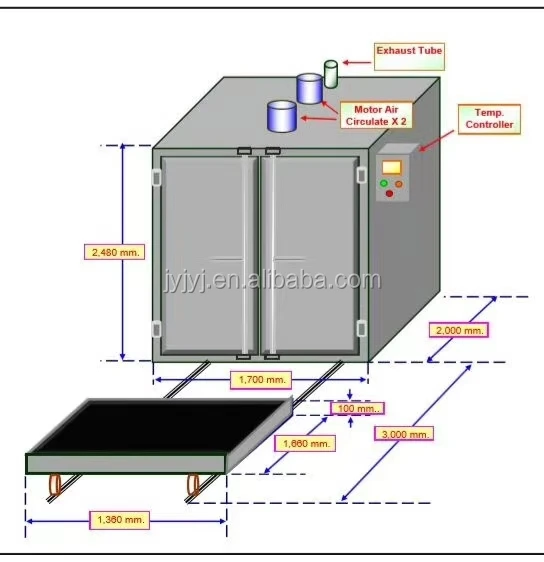

Heating oven: (don't have to pack, would increase the cost of coating auxiliary power, master advice off).

6, electrical control, manual, semiautomatic and fully automatic control mode has, controlled by PLC + 10.4 "touch screen, the main components adopt domestic and Japan, French brand products.Has overcurrent, overload, overheating protection function.Equipment with water shortage protection functions such as alarm at the same time.The valve self-locking interlock.

7, gas supply system: with 1 road Beijing gas mass flow controller, 1000 s.(can be equipped with a set of other billing).

8, vacuum parameters:

(1), the extraction speed: from the atmosphere to the 5 x 10-3 pa 15 minutes or less (light, clean room)

Best regards;Looking forward to your reply!

Wechat: nbjunying