Оборудование для производства Текстурированного Соевого Белка TVP по заводской

- Категории: Оборудование для переработки бобовых продуктов >>>

- Поставщик: Jinan,Sunward,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

TVP Textured Soy Protein Production Equipment Machinery with factory price

1. Brief Introduction

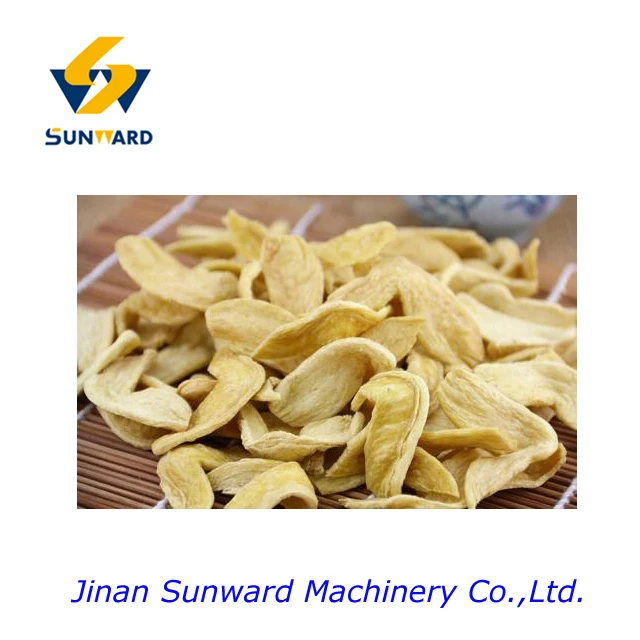

Textured Soy Protein is made from defatted soy flour, which is low oil soy material. So it is plentiful in supply. It is with a great source of vegetable protein without all the fat. Texture Soy protein comes in small dry chunks resembling,well,dried vegetables more than anything, or in a finely-ground form. It's flavorless, but when you re-hydrate it and add your own flavors, it makes a great protein-filled addition to many dishes calling for ground meat.Because of its varying texture, it's versatile, and can take on the texture of many meats. For instance, it's excellent in chili, tacos, veggie burgers and soups. With muscle structure, it has better absorbency and can defend without cholesterol. It can be boiled in high temperature with different tastes, or added into meal product as stuffing. When it's used to replace meat in stews and soups, your family will hardly be able to tell the difference and since you can marinate it in many of the same sauces as meat, it can take on meat's flavors.

2. Capacity: 100-500kg/h

3. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'local voltage according to different countries.

4. Machines Materials: All the machines are made by stainless steel.

5. Flow chart: Mixer--- Screw Conveyor --- Twin-screw extruder --- Air conveyor --- Dryer --- Cooling machine

Main Features

Textured Soy Protein making machine adopts defatted soya flour as raw materials. This production line can be used to produce textured soy protein.

Model | Installed Power | Power Consumption | Production Capacity | Dimension |

TSE 65-S | 90 kw | 60 kw | 200-260 kg/h | 18000*1300*2300 mm |

TSE 85-S | 160 kw | 120 kw | 300-550 kg /h | 22000*3500*3200 mm |

Twin- screw extruder (TSE 65-S)

Installed Power: 53 kw

Consumption: 37 kw/h

Output: 200 kg /h-250 kg/h

Size: 2600*870*1950 mm

The screws are made of the alloy steel and special craft, durable usage, high pressure,the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

Mixer

Installed Power: 4 kw

Consumption: 3 kw/h

Output: 30 kg/batch-40 kg/batch

Mixing Time:(2 minutes-3 minutes)/batch

Size: 1030*920*1350 mm

Function: raw material with water, liquid chemical additive mix together fully.

Multi-layer Dryer

Installed Power: 45 kw

Consumption: 30 kw/h

Output: 200 kg/h-300 kg/h

Size: 5200*1300*2200 mm

Function: Baking and drying the food. All kinds of the inflating food, pet food, TVP /TSP food,peanut, nut, chew nut can be dried.

Cooling machine

Installed Power: 1 kw

Output:According to Extruder

Size:5000*700*1100 mm

Feature:

1.This material that contacts food adopts the stainless steel material.

2.The air from the fan cooling the rice going through the conveyor belt.

3.Motor is Chinese famous brand

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | According to the different size of different machine. | |

Weight | According to the different size of different machine. | |

Packaging Details | The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

I. What's the pre-sale service of your company?

Related machines's technical parameter will be supplied to customer.

1. According to customer's factory size, factory layout can be provided in advance.

2. According to customer's material cost, general formulation can be prepared well.

3. Special machine can be supplied as customer's request.

4. Professional Advice about Market, machines, processing , materials, packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customer request.

II. What's the after-sale service of your company?

1. Allocation chart as the buyer's request will be supplied.

2. Operation manual will be supplied after shipment.

3. One year warranted, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container .

5. First installation can be done by engineer.

6. Training workers in customer's factory.

III. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

IV. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.