Полностью автоматическая аварийная огнеупорная машина для производства

- Категории: Другие текстильные машины >>>

- Поставщик: Zhejiang,Runtai,Automation,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Machine Photo

Product Description

SPECIFICATIONS | ||||||

Speed | 0-70 m/min | |||||

Voltage | 380V | |||||

Power | 1.5kw | |||||

Machine Weight | 1500kgs | |||||

Machine size | 4000*1000*1800 MM (L*W*H) | |||||

Adjustment Range | 1000mm - 3000mm | |||||

Main Features

Emergency blanket folding machine production process: raw materials molding machine → Portrait → → fast interrupt automatic folding → Release Paper Emergency blanket folding machine equipment configuration:

1,1.5KW Delta inverter motor drive.

2, the side of the two pairs of clamping rollers and the folding rollers is fixed and can not adjust the structure, between the rollers should ensure that the base plate parallel to each other and perpendicular. The gap between the pair of rollers with the other side of the adjustment, adjustment range from 0 to 0.4 mm. Adjust the way with the handle with fine thread adjustment handle should be arranged outside the chassis and set tightening mechanism.

3, in addition to the main motor drive and servo interrupt transmission arranged in the lower rack, other transmission should be arranged on a rack for easy adjustment and maintenance.

4, automatic counting device after a certain number of material with automatic folding quickly brought out a good product.

5, breaking part of Panasonic 1KW servo motor, operating in the form of pre-acceleration, the pre-decelerating, and pre-acceleration short segment, pre-decelerating long knife cut to ensure the highest speeds and accurately stop when the break after break.

6, the product length on the touch screen can be adjusted (adjustment range 1000mm ~ 3000mm).

7, emergency blanket folding machine production speed ≤70 meters per minute, breaking speed ≤70 meters.

8, break times count (continuous count and cleared at any time).

9, breaking length (length can be set continuously interrupted, control error of plus or minus 5 mm).

10, discharge using air shaft, raw tension from the magnetic brake. Note: Special specifications, demand-made

Packing & Delivery

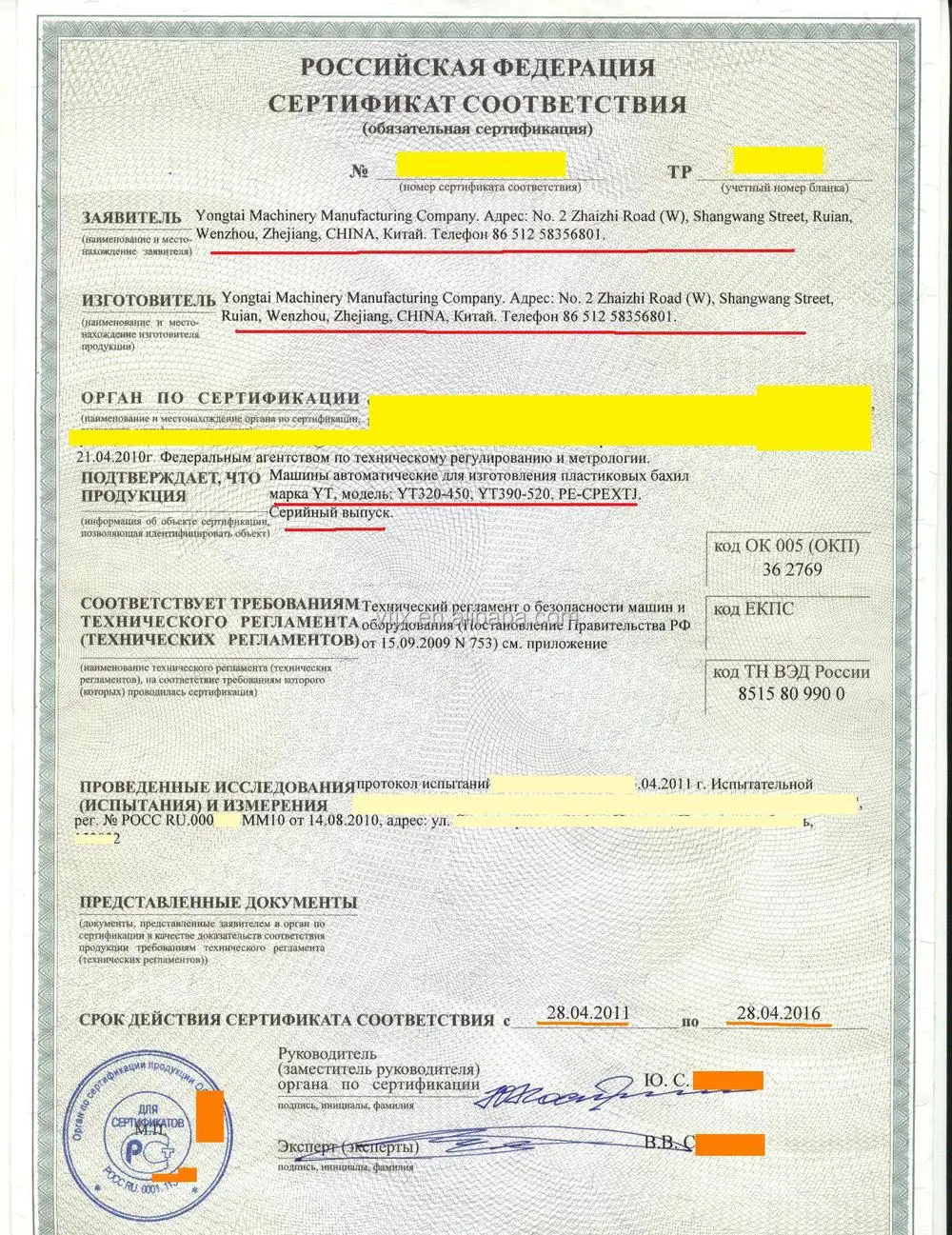

Certifications

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Warranty: 1 year

After-Sales Service

* Lifelong

* Free spare parts

* Video technical and online support

* Field maintenance and repair service

* Field installation, commissioning and training

* Engineers available to service machinery overseas.

Contact

Contact Person | Andy | ||||

Alibaba | cn1001403657 | ||||

Email | salesATyongtaijixie.cn | ||||

Skype | yongtaimachinery88 | ||||

What's App | +8613676596822 | ||||

Fax | 0086-577-58802703 | ||||

Add | No.4, Building E, No.188, Wangxin Road,Ruian Economic Development Zone | ||||

Ruian, Zhejiang Province | |||||

Related Products