Полировка драгоценных камней промышленная зернистость Алмазный кристалл микро

- Категории: Абразивы >>>

- Поставщик: Zhecheng,Hongxiang,Superhard,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

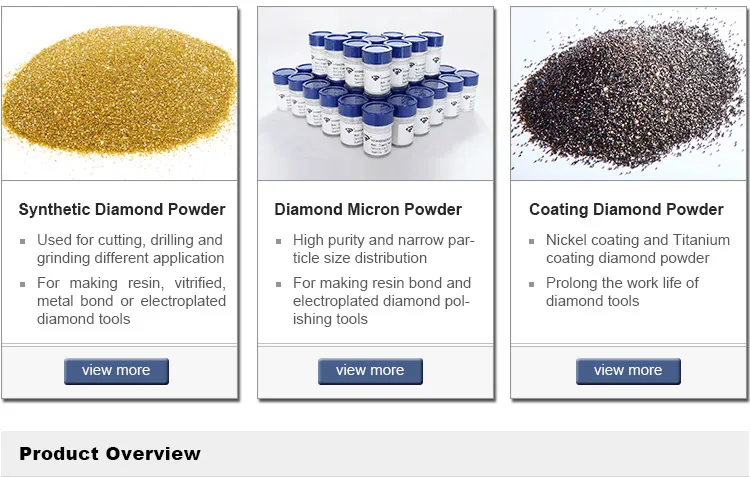

Description HNHONGXIANG synthetic diamond powder is made of the high-quality synthetic diamond as raw material, through many different and strict production processes. Our diamond powder can be processed and applied to the different industries for cutting, grinding, drilling and polishing usage, in order to match the different requirements.

Description HNHONGXIANG synthetic diamond powder is made of the high-quality synthetic diamond as raw material, through many different and strict production processes. Our diamond powder can be processed and applied to the different industries for cutting, grinding, drilling and polishing usage, in order to match the different requirements.

1.Feature:Irregular crystal form with rough surface, low impurity, high grinding strength.

1.Feature:Irregular crystal form with rough surface, low impurity, high grinding strength.

2.Usage:For making resin, vitrified bond or elecplated diamond tools. Diamond grinding wheels, diamond abrasives Fickert, diamond pads, electroplating diamond grinding files, etc.

3.Workpiece Material:Stone, ceramic, glass, concrete, hard alloy, etc. 1.Feature:Economical grade of RVD, high cost-effective. Sharp and irregular shape.The good friability help to enhance the self-sharpening ability and free cutting property, thus, effectively increase the productivity and grinding efficiency.

2.Usage:For making resin bond diamond tools, diamond grinding wheels, diamond abrasive Fickert, diamond pads, etc.

3.Workpiece Material:Tungsten carbides, glass, ceramics and stone material, etc.

1.Feature:MBD series - MBD0, MBD1, MBD2, MBD3, MBD4, MBD5, MBD6, MBD8, MBD10, MBD12. The grade of diamond is higher, the diamond powder has the much better hardness, wear resistance, and thermal stability, fewer impurities, and the more regular blocky shaped perfectly octahedral crystals.

1.Feature:MBD series - MBD0, MBD1, MBD2, MBD3, MBD4, MBD5, MBD6, MBD8, MBD10, MBD12. The grade of diamond is higher, the diamond powder has the much better hardness, wear resistance, and thermal stability, fewer impurities, and the more regular blocky shaped perfectly octahedral crystals.

2.Usage:For making metal bond or electroplated diamond tools, diamond drill bits, diamond saw blades, diamond grinding wheels, diamond wire saw, diamond roller, diamond squaring wheels, etc.

3.Workpiece Material:Ceramic, stone, concrete, refractory, etc.

1.Feature:The highest grade of diamond powder series, SMD25, SMD30, SMD35. Regular blocky shaped perfectly octahedral crystal form, high purity, high hardness and wear resistance, and thermal stability.

1.Feature:The highest grade of diamond powder series, SMD25, SMD30, SMD35. Regular blocky shaped perfectly octahedral crystal form, high purity, high hardness and wear resistance, and thermal stability.

2.Usage:For making metal bond diamond tools, mining and geological diamond drill bits, diamond saw blades, diamond drilling bits, diamond wire saw, etc.

3.Workpiece Material:Stone, concrete applications and construction industries. 1.Diamond Micron Powder Feature: General grade diamond micron powder for multi-purpose Manufactured on the basis of the diamond industry standard, which is the multi-purpose product. Relatively regular crystal form, good hardness and impact resistance, and few impurities, comparatively narrow particle size distribution.

2.Diamond Micron Powder Usage : for making the resin bond, vitrified bond or electroplated diamond wheels, diamond pads, diamond abrasive Fickert, diamond lappato, or diamond lapping paste, etc.Less Impurities and lowder magnetic.

3.Diamond Micron Powder Workpiece Material: Aim of grinding and polishing glass, ceramic, stone, concrete, gemstone, hard alloy, wire die, sapphire, semiconductors, etc.

1.Feature:Rough and spiny surface, improve the retention between diamond and bond, avoid the diamond peeling off early, thus, extend the service life of diamond tools.

1.Feature:Rough and spiny surface, improve the retention between diamond and bond, avoid the diamond peeling off early, thus, extend the service life of diamond tools.

2.Feature:Rough and spiny surface, improve the retention between diamond and bond, avoid the diamond peeling off early, thus, extend the service life of diamond tools.

3.Usage:Recommend for making resin bond diamond tools, for example, resin bond diamond grinding wheel.

1.Feature:Avert to oxidize and graphitize when the diamond powder during the high-temperature circumstance. Reduce the heat damage, effectively extend the service life of diamond tools.

1.Feature:Avert to oxidize and graphitize when the diamond powder during the high-temperature circumstance. Reduce the heat damage, effectively extend the service life of diamond tools.

2.Type:Gain weight 1% to 3%.

3.Usage:Recommend for making metal bond diamond tools.

| Grit | RVG | RVD | MBD0 | MBD1 | MBD2 | MBD3 | MBD4 | MBD5 | MBD6 | MBD8 | MBD10 | MBD12 | SMD25 | SMD30 | SMD35 |

| 30/35 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 35/40 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 40/45 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 45/50 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 50/60 | √ | √ | √ | √ | √ | √ | |||||||||

| 60/70 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 70/80 | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| 80/100 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 100/120 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 120/140 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 140/170 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 170/200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 200/230 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 230/270 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 270/325 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 325/400 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 400/500 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Standard of China | Standard of International | Mesh | D50um | Standard of China | Standard of International | Mesh | D50um |

| W0.25 | 0-0.25 | 60000 | 0.11~0.20 | W0.5 | 0-0.5 | 30000 | 0.20~0.30 |

| W1 | 0-1 | 15000 | 0.6~0.8 | W1.5 | 0-2 | 13000 | 1 |

| W1.5 | 1-2 | 12000 | 1.1~1.3 | W2.5 | 1-3 | 10000 | 1.6`1.8 |

| W3 | 2-3 | 7000 | 1.9~2.1 | W3.5 | 2-4 | 6500 | 2.2~2.6 |

| W3.5 | 2-4 | 6000 | 2.6~3.0 | W4 | 2-5 | 5000 | 3.1~3.4 |

| W5 | 3-6 | 4000 | 3.5~4.2 | W6 | 4-6 | 3500 | 4.4~5.0 |

| W7 | 4-8 | 3000 | 5.0~6.0 | W10 | 4-9 | 2500 | 6.1~6.5 |

| W10 | 5-10 | 2000 | 6.5~7.3 | W10 | 6-12 | 1800 | 7.3~8.3 |

| W12 | 8-12 | 1600 | 8.3~9.0 | W14 | 7-14 | 1500 | 9.1~10.5 |

| W14 | 8-16 | 1300 | 10.0~12.0 | W20- | 10-20 | 1200 | 12.5~15.0 |

| W20 | 12-22 | 1000 | 15.0~17.0 | W20+ | 15-25 | 800 | 18.0~20.0 |

| W28 | 20-30 | 700 | 20~23 | W28+ | 22-36 | 600 | 23~26 |

| W40- | 20-40 | 500 | 26~29 | W40 | 30-40 | 450 | 29~32 |

| W40+ | 35-45 | 400 | 32~36 | W50 | 36-54 | 37~43 | |

| 325/400 | 320 | 43~48 | 270/325 | 280 | 48~55 | ||

| 230/270 | 240 | 56~64 | 200/230 | 200 | 65~73 |

For more details about price,packing,shipping and discount. Tel: 86-0371-86038278

For more details about price,packing,shipping and discount. Tel: 86-0371-86038278

Cel: 86-13613801611

Web: www.hnhongxiang.com