Листогибочный станок с ЧПУ DELEM DA66T MB8 200T

- Категории: Оборудование для обработки металлических листов >>>

- Поставщик: Maanshan,Durmapress,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

CNC Press Brake

The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

1. High bending precision,fast working speed, and efficient,operational safety,performance stably.

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc.

4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. All parts are produced by cnc produce center,according to standard drawing.

6. High executive force,high standard and high professional machine assembled team.

7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

9. Providing comprehensive bending program for all press brake,shearing machine user.

10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

13.The similarity of images and shipping machine can reach 99.5%.

14.In time fast delivery.

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc.

4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. All parts are produced by cnc produce center,according to standard drawing.

6. High executive force,high standard and high professional machine assembled team.

7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

9. Providing comprehensive bending program for all press brake,shearing machine user.

10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

13.The similarity of images and shipping machine can reach 99.5%.

14.In time fast delivery.

Model | MB8 200T 3200 | ||||

Pressing force | 2000 | KN | |||

Working length | 3050 | MM | |||

Distance between uprights | 2600 | MM | |||

Stroke | 250 | MM | |||

Distance table/ram | 485 | MM | |||

Gap | 400 | MM | |||

Table width | 200 | MM | |||

Apprach speed | 100 | MM/S | |||

Working speed | 11 | MM/S | |||

Return speed | 120 | MM/S | |||

Motor | 22 | KW | |||

Volume of oil tank | 550 | L | |||

Overall Dimension | 3800*1900*2800 | MM | |||

Main Configuration

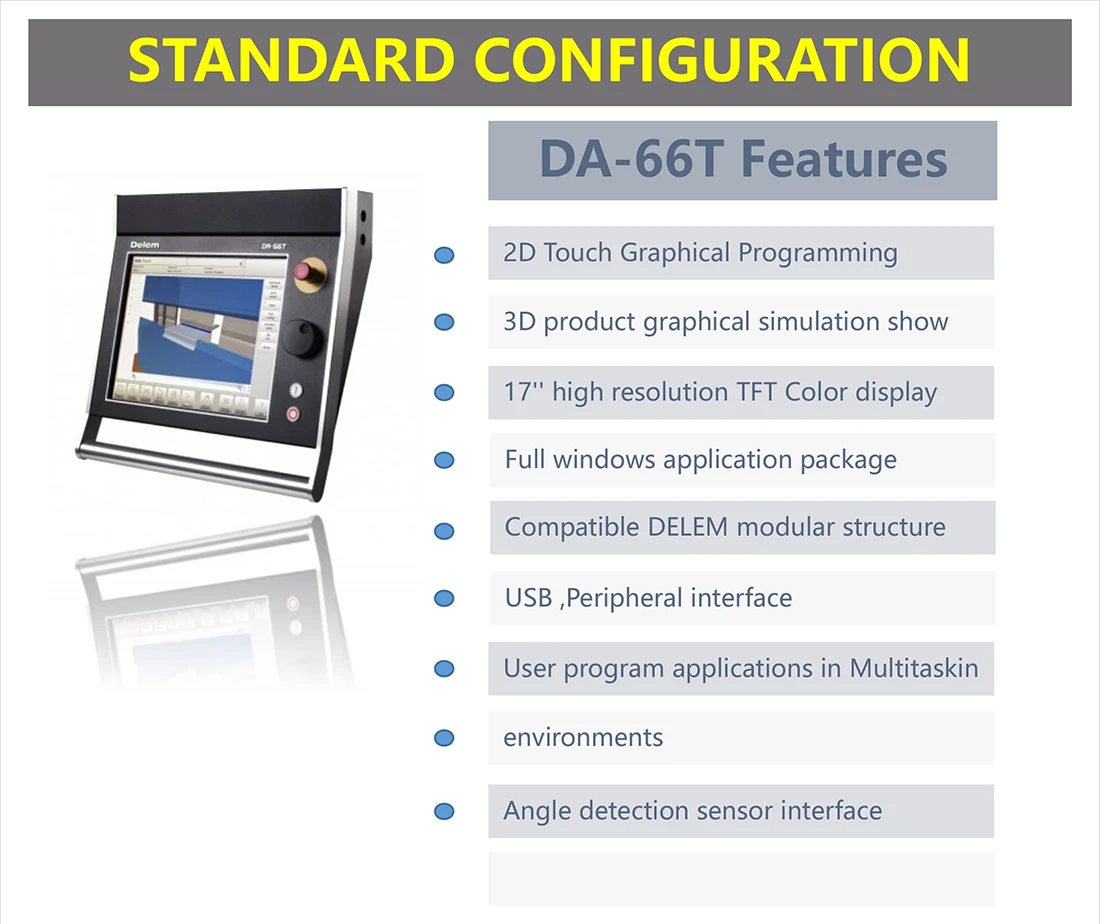

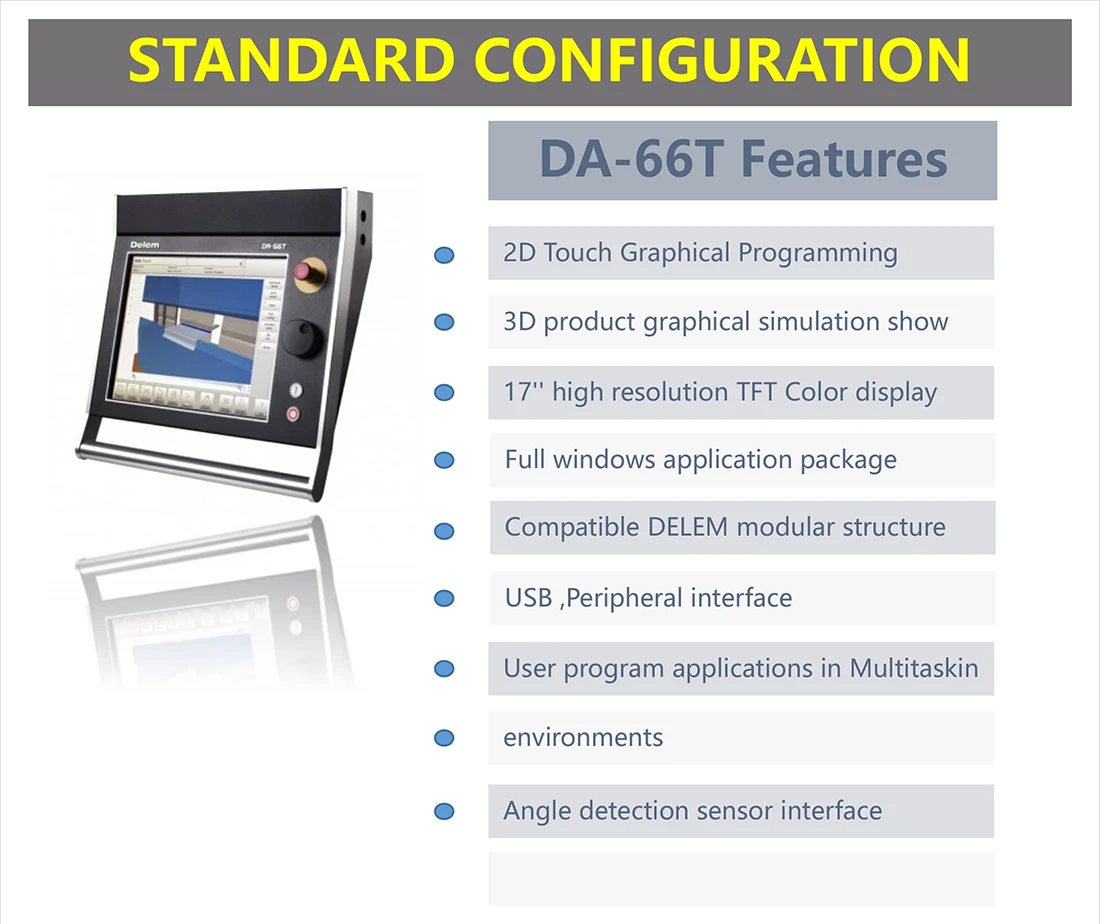

DA66T CNC Controller

Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Automatic Mechanical compensation

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

Detailed Images

Fast Clampings

Standard double V lower die with different size and various shaped slots for choice ,convenient for exchanging dies,capable for bending regular plates, with high cost performance CNC double-V die workbench,convenient for installation of segmented dies

Siemens Motor

German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment

Mechanical Crowning Worktable

Through compensation, the angle of the workpiece is prevented from increasing in the full length range, the angle and linear accuracy of the bent workpiece are effectively improved.

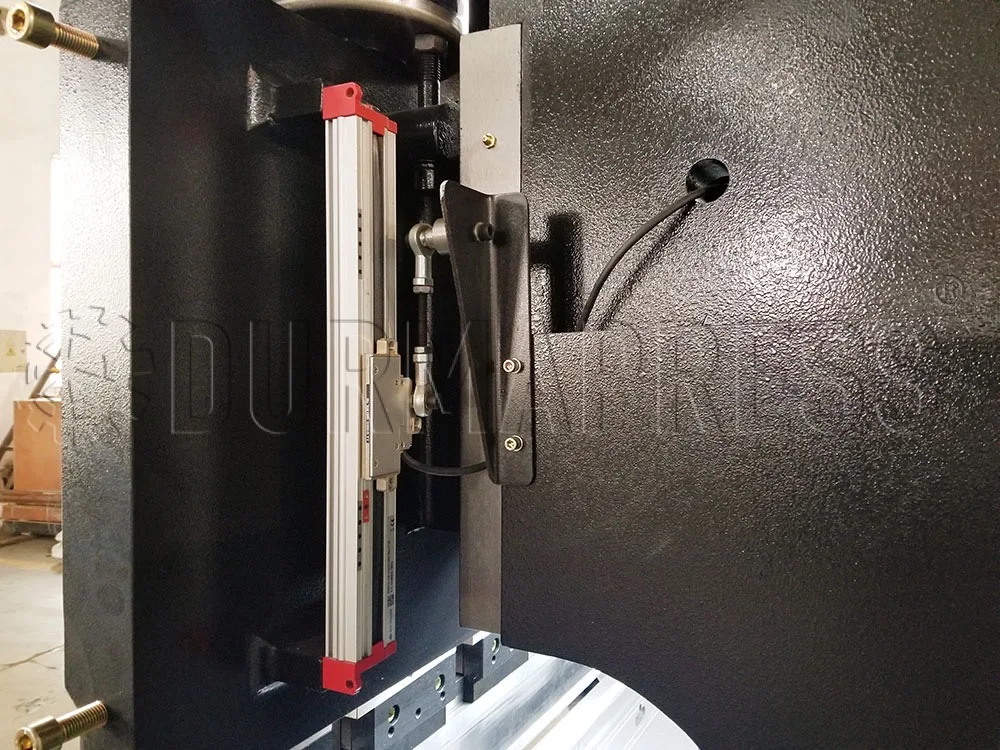

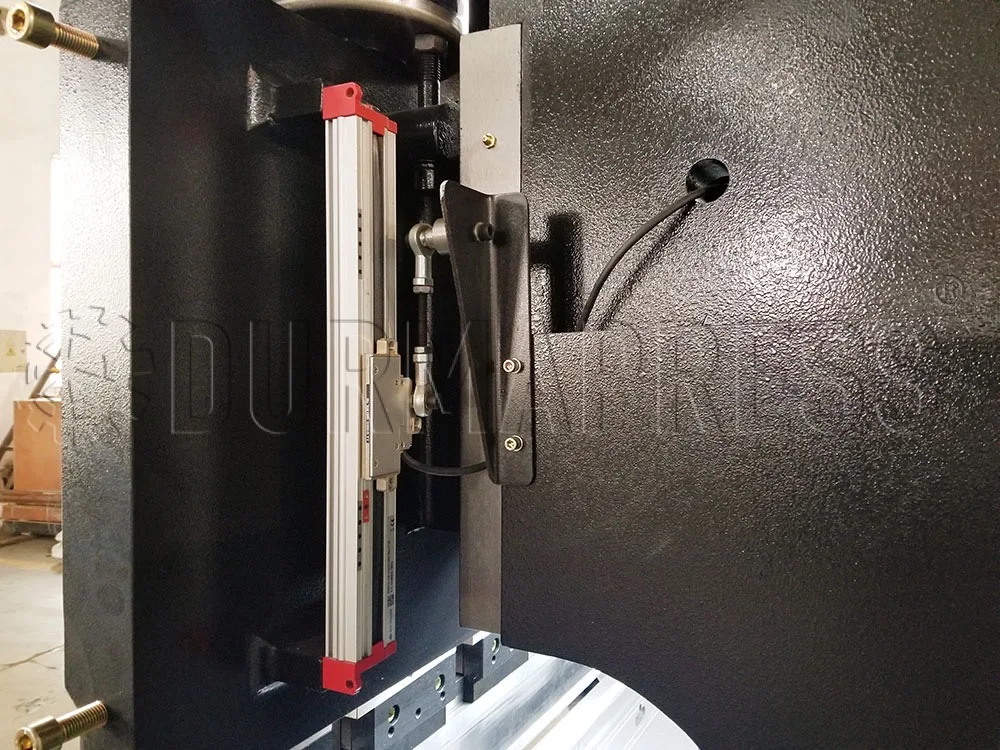

Spain FAGOR Grating Ruler

Slider position signal is feedbacked to controller by spain FAGOR Grating ruler, then the CNC Controller adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider ( Y1,Y2) running on the same frenquency ,maintaining the parallel state of the worktable

Press Brake Tooling

Press Brake toolings are made from 40CrMo Materials with hardness up to 52 degrees to ensuring die service life

Front Supportor

Front supporter with features of simple structurer, powerful functions ,can be adjusted up and down , or moved along the workbench in rightwards and leftwards

Backgauge

6 Axis CNC Backgauge ,including the R1 R2 ; X1 X2 ; Z1 Z2 ,can move up and down ; front and back , left and right , the fine adjustment with high accuracy up to ± 0.02mm